Aqueous ink PVC floor

A water-based ink and flooring technology, applied in the field of plastic flooring, can solve problems such as pollution, consumer health damage at home, printing workers and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of water-based ink PVC floor, the preparation method of described PVC floor comprises the steps:

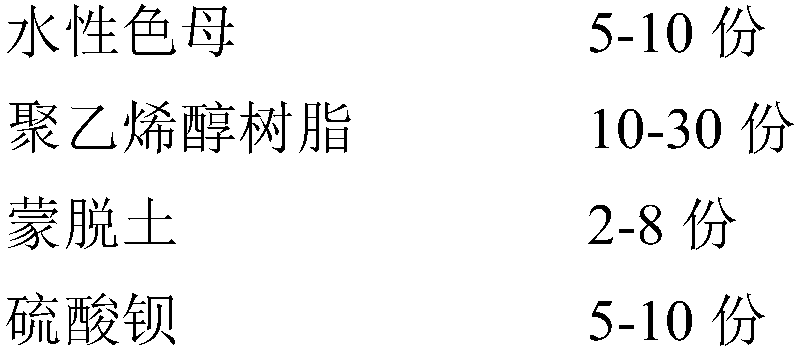

[0025] A. Preparation of PVC floor water-based ink:

[0026] (1) Add 2 parts of montmorillonite, 10 parts of barium sulfate, and 40 parts of water into the dispersion kettle in sequence, and stir at a speed of 200rpm, then add 10 parts of water-based color masterbatch, stir and mix evenly at a speed of 200rpm, and then use Three-roll mill grinding to a particle size of less than 500nm to obtain an inorganic premix;

[0027] (2) At room temperature, mix the inorganic premix prepared in step (1), 10 parts of polyvinyl alcohol resin, 1.5 parts of silicone defoamer and 30 parts of sodium hydroxypropyl cellulose, and stir for 30 minutes at a speed of 300 rpm , followed by filtering and discharging to obtain the water-based ink.

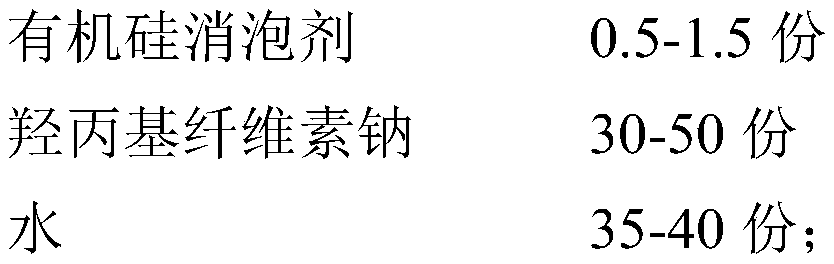

[0028] B. Preparation of PVC floor film

[0029] (1) Heat 100 parts of polyvinyl chloride resin to 80 ° C, add 15 parts of calcium carbonate...

Embodiment 2

[0033] A kind of water-based ink PVC floor, the preparation method of described PVC floor comprises the steps:

[0034] A. Preparation of PVC floor water-based ink:

[0035] (1) Put 8 parts of montmorillonite, 5 parts of barium sulfate, and 35 parts of water into the dispersion kettle in sequence, and stir at a speed of 100rpm, then add 5 parts of water-based color masterbatch, stir and mix evenly at a speed of 150rpm, and then use Three-roll mill grinding to a particle size of less than 500nm to obtain an inorganic premix;

[0036] (2) At room temperature, mix the inorganic premix prepared in step (1), 30 parts of polyvinyl alcohol resin, 0.5 part of silicone defoamer and 30 parts of sodium hydroxypropyl cellulose, and stir for 60 minutes at a speed of 200 rpm , followed by filtering and discharging to obtain the water-based ink.

[0037] B. Preparation of PVC floor film

[0038] (1) Heat 100 parts of polyvinyl chloride resin to 80°C, add 10 parts of calcium carbonate, 10 ...

Embodiment 3

[0042] A kind of water-based ink PVC floor, the preparation method of described PVC floor comprises the steps:

[0043] A. Preparation of PVC floor water-based ink:

[0044] (1) Add 6 parts of montmorillonite, 8 parts of barium sulfate, and 38 parts of water into the dispersing kettle in turn, stir at a speed of 100-200rpm, then add 8 parts of water-based color masterbatch, and stir and mix at a speed of 150-200rpm Uniform, and then use a three-roll mill to grind to a particle size of less than 500nm to obtain an inorganic premix;

[0045] (2) At room temperature, mix the inorganic premix prepared in step (1), 20 parts of polyvinyl alcohol resin, 1 part of silicone defoamer and 50 parts of sodium hydroxypropyl cellulose, and stir for 40 minutes at a speed of 250 rpm , followed by filtering and discharging to obtain the water-based ink.

[0046] B. Preparation of PVC floor film

[0047] (1) Heat 100 parts of polyvinyl chloride resin to 75°C, add 12 parts of calcium carbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com