Ultra-light high-modulus high-strength casting aluminum-lithium matrix composite and preparation method thereof

A composite material and casting aluminum technology, which is applied in the field of metal materials and metallurgy, can solve problems such as poor wettability, achieve the effects of reducing hydrogen absorption and oxidation, obvious refinement effect, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to an ultra-light, high-modulus, high-strength cast aluminum-lithium-based composite material and a preparation method thereof. The preparation method is specifically:

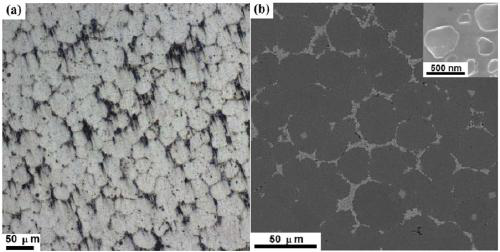

[0038] Firstly, TiB was prepared by in situ authigenic molten salt reaction 2 / Al base material, the specific steps are as follows: pure aluminum as the base material, NaBF 4 and Na 2 TiF 6 As a reaction mixture salt supplemented with Na 3 AlF 6 、LiF 3 , LiCl 3 As a reaction auxiliary agent, the ratio is 2:1:1, the total amount is 10% of the reaction mixed salt, the reaction auxiliary agent is added at a temperature of 760 ° C, and the reaction time is 30 minutes; rotating and blowing argon for stirring, and the rotor speed is 300r / min, the flow rate of argon gas is 10L / min; the intensity of the pulsed magnetic field is controlled at 1.5T, and the intensity of the high-energy ultrasonic field is controlled at 200W / m 2 , to prepare TiB 2 In situ reinforcement of pure alu...

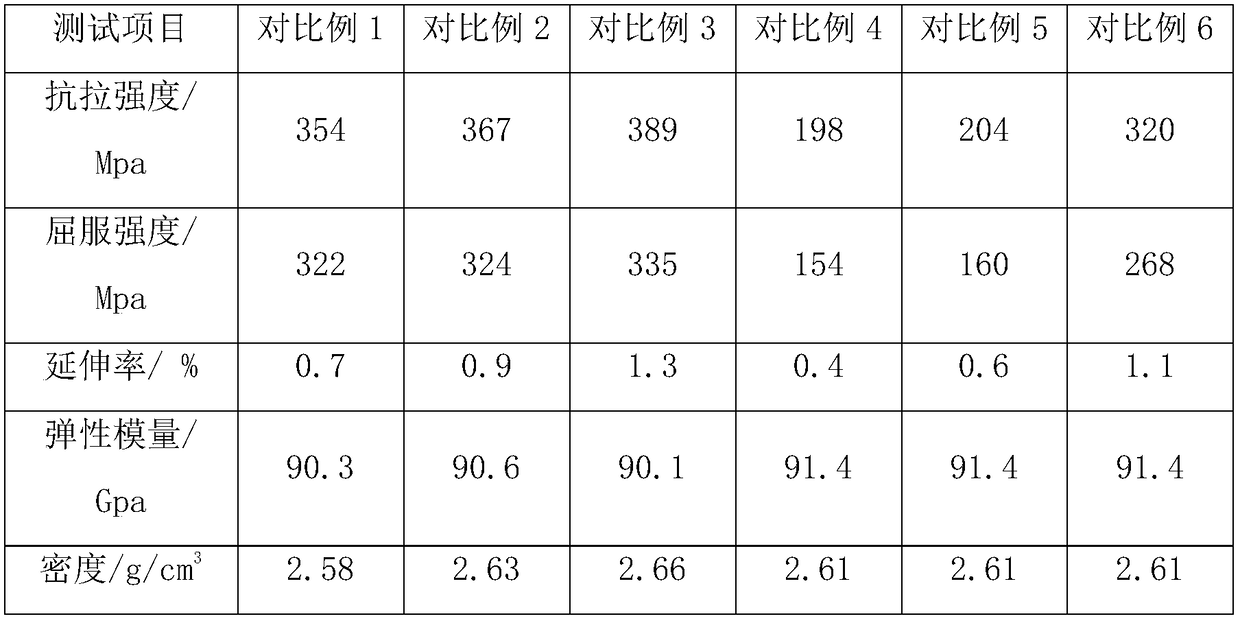

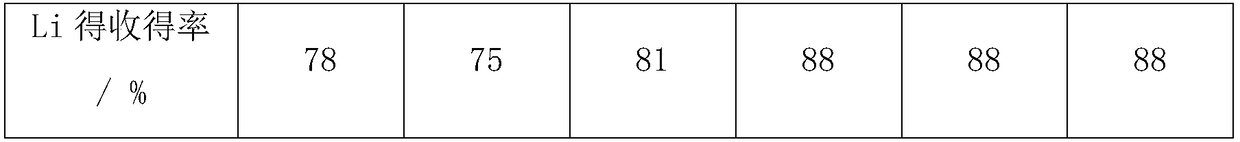

Embodiment 2

[0049] This embodiment relates to an ultra-light, high-modulus, high-strength cast aluminum-lithium-based composite material and a preparation method thereof. The preparation method is specifically:

[0050] Firstly, TiB was prepared by in situ authigenic molten salt reaction 2 / Al base metal, preheat base metal, pure aluminum, Al-Mg master alloy, Al-Cu master alloy to about 200℃, and then TiB 2 / Al base metal and pure aluminum are melted in a molybdenum crucible. After the aluminum ingot is melted, add the Al-Cu master alloy at 750-760 °C, wait for the temperature of the aluminum liquid to rise to 750-760 °C, then add the Al-Mg master alloy into the aluminum liquid, and keep it warm for 5 minutes after the temperature is stable. After the heat preservation is over, add Al-Zr, Al-Sc, and Al-Cd master alloys in sequence at 750-760 °C, stir evenly after they are completely melted, and sprinkle the covering agent (3:1=LiCl:LiF) on the surface of the melt . Subsequently, the A...

Embodiment 3

[0059] This embodiment relates to an ultra-light, high-modulus, high-strength cast aluminum-lithium-based composite material and a preparation method thereof. The preparation method is specifically:

[0060] Firstly, TiB was prepared by in situ authigenic molten salt reaction 2 / Al base metal, preheat base metal, pure aluminum, Al-Mg master alloy, Al-Cu master alloy to about 200℃, and then TiB 2 / Al base metal and pure aluminum are melted in a molybdenum crucible. After the aluminum ingot is melted, add the Al-Cu master alloy at 750-760 °C, wait for the temperature of the aluminum liquid to rise to 750-760 °C, then add the Al-Mg master alloy into the aluminum liquid, and keep it warm for 5 minutes after the temperature is stable. After the heat preservation is over, add Al-Zr, Al-Sc, and Al-Cd master alloys in sequence at 750-760 °C, stir evenly after they are completely melted, and sprinkle the covering agent (3:1=LiCl:LiF) on the surface of the melt . Subsequently, the A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com