Element with hydrogen absorption and desorption and foreign gas adsorption functions and preparation method thereof

A technology for impurity gas, hydrogen absorption and desorption, applied in electrical components, spark gap parts, spark gaps with auxiliary triggering devices, etc. The effect of improving hydrogen absorption rate and hydrogen absorption capacity, and high effective reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

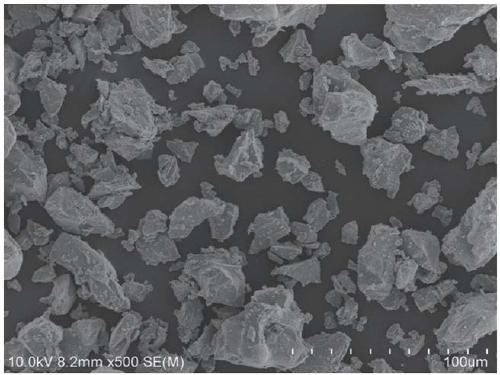

[0038] The hydrogen absorbing and desorbing alloy component, that is, the TiZr alloy is melted in a vacuum suspension furnace at 1600°C according to the atomic percentage of 3:1, and the alloy ingot obtained after the furnace is cooled is crushed to 20 mesh by crushing ball milling in an argon protective atmosphere, and the powder enters the airflow Grinding, the grinding gas is argon (purity ≥ 99.999%), the pressure is 0.50MPa, and the sorting frequency is 60Hz. Collect the powder to obtain TiZr powder, the microscopic appearance is as follows figure 1 As shown, the powder particles are of irregular geometric shape with a diameter of ≤50 μm.

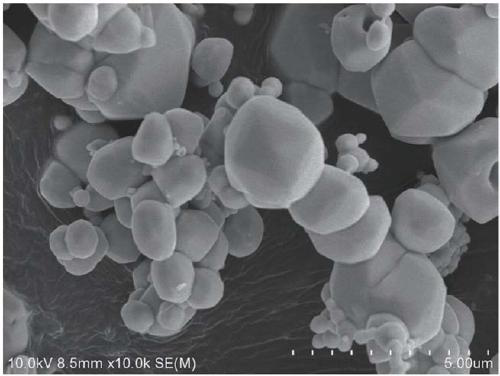

[0039]Add 12mol% Mo powder in the obtained TiZr powder, the microscopic appearance of Mo powder is as follows figure 2 As shown, the powder particles are spherical, with a diameter ≤ 10 μm, and the hydrogen absorption and desorption alloy Ti 0.66 Zr 0.22 Mo 0.12 .

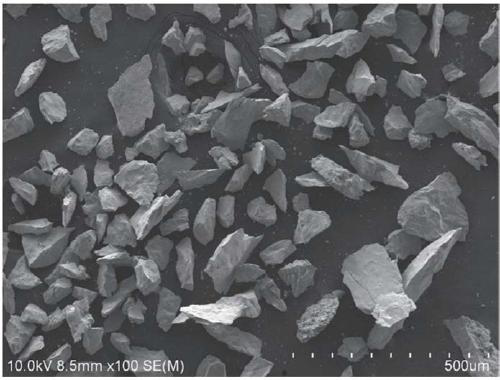

[0040] The impurity gas is adsorbed to the alloy composition, tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com