Draining structure

A technology of drainage structure and parapet wall, applied in the direction of roof drainage, building structure, roof, etc., can solve the problem that the width of the drainage ditch cannot meet the drainage requirements, the angle between the connecting rods of the support nodes is too much, and it is difficult to realize the longitudinal slope of the drainage ditch. and other problems, to achieve the effect of saving steel consumption, less connecting rods, and large width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

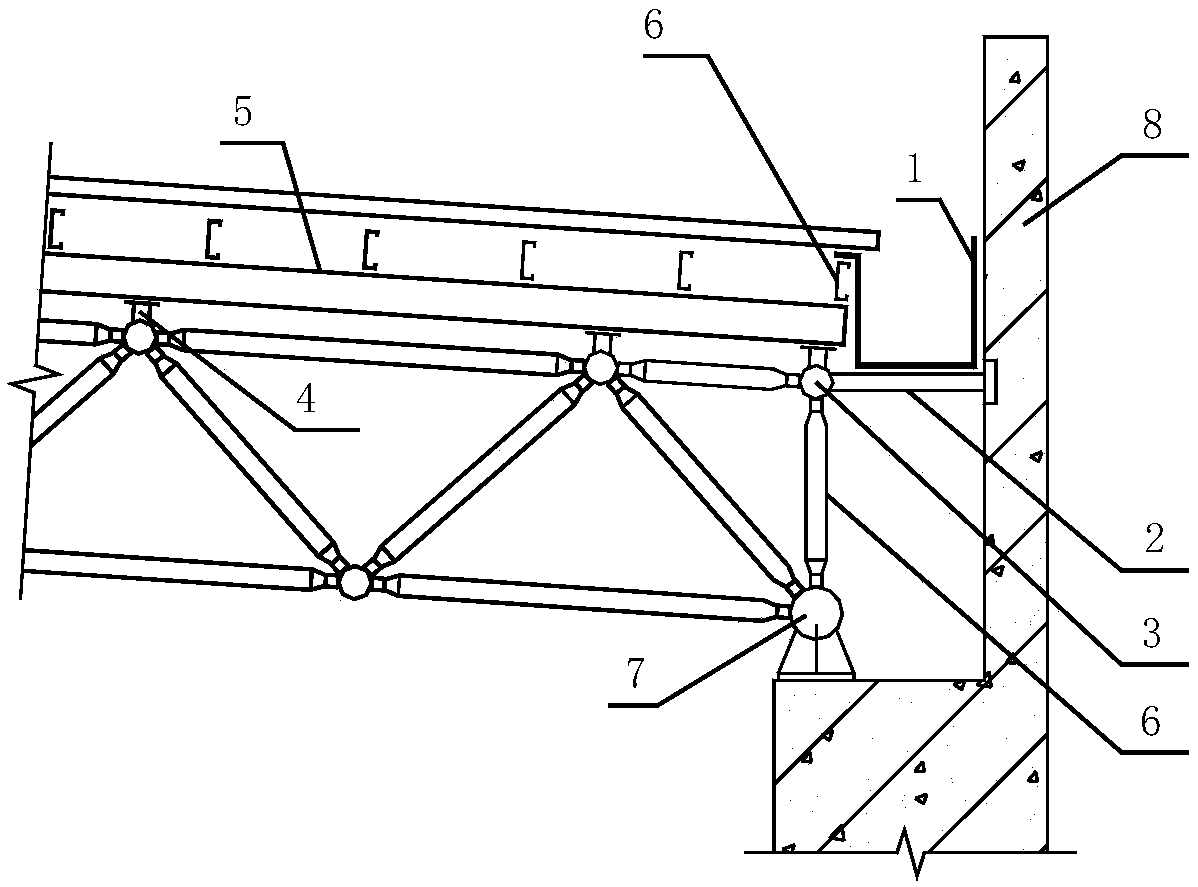

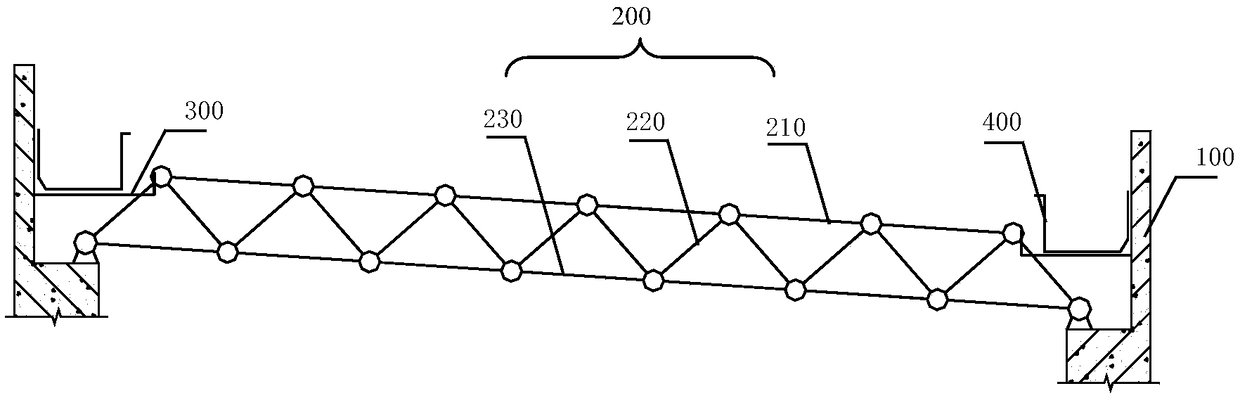

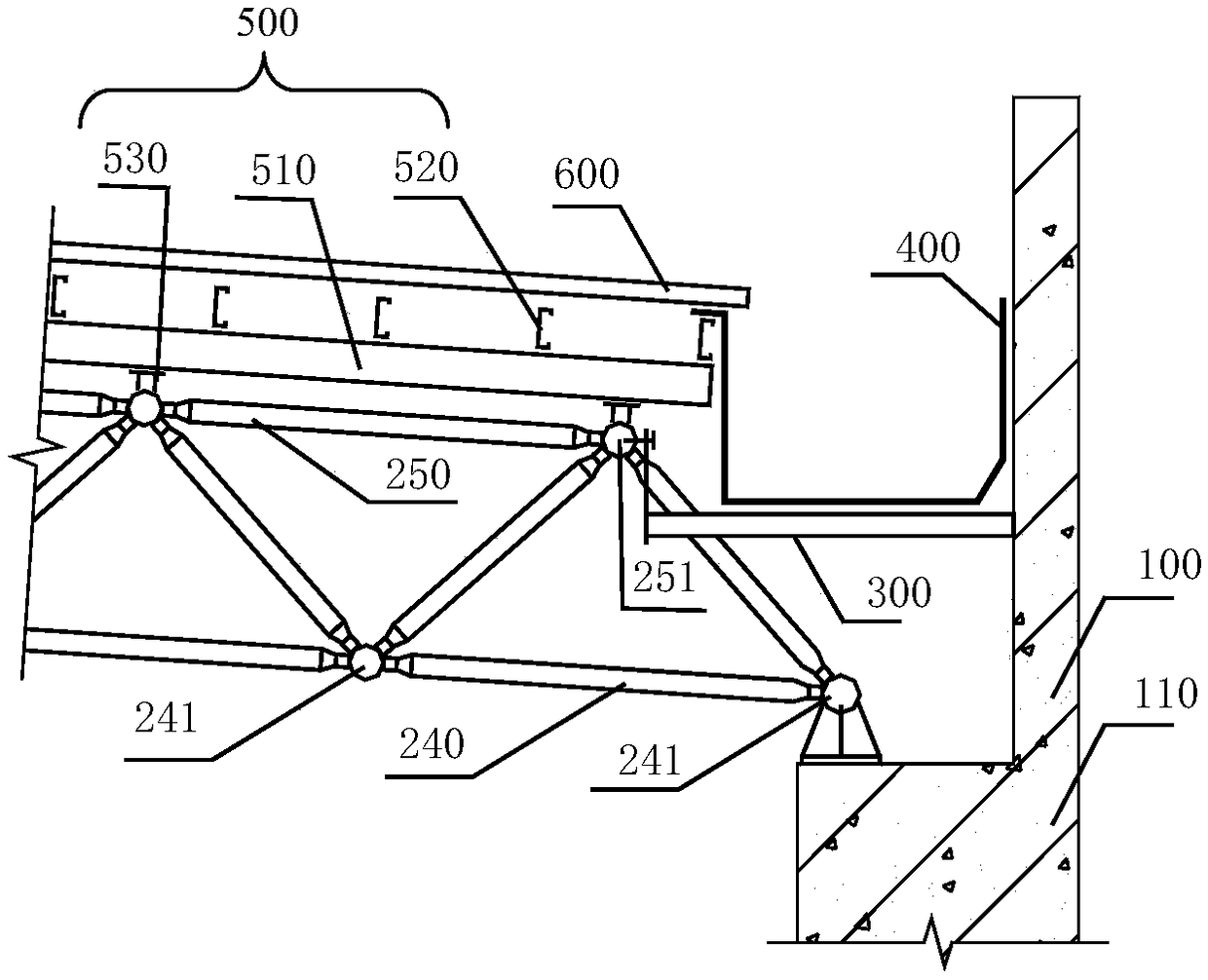

Embodiment 1

[0069] A drainage structure with a structure such as Figure 2-5 As shown, the size of the upper chord planar grid components of the grid frame is smaller than the size of the lower chord plane grid components, the number of ball nodes on the upper string string of the grid frame is smaller than the number of ball nodes on the lower string string of the grid frame, and the cross section of the grid frame is a trapezoid with a small top and a large bottom. Connect a gutter support beam between the first volleyball node near the parapet on the upper chord plane and the parapet. One end of the support beam is fixed on the first volleyball node of the upper chord plane grid assembly near the parapet by hanging the steel plate, and the other end is fixed on the parapet wall by the steel plate through expansion bolts. The height of the support beam is between the upper and lower chord plane grid components between. The gutter is located on the supporting beam, and the gutter is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com