Liquid crystal glass sheet alignment laminating machine

A liquid crystal glass, laminating machine technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of long operation time, low processing efficiency, high use cost, etc., to achieve low use cost, high production efficiency, alignment Quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

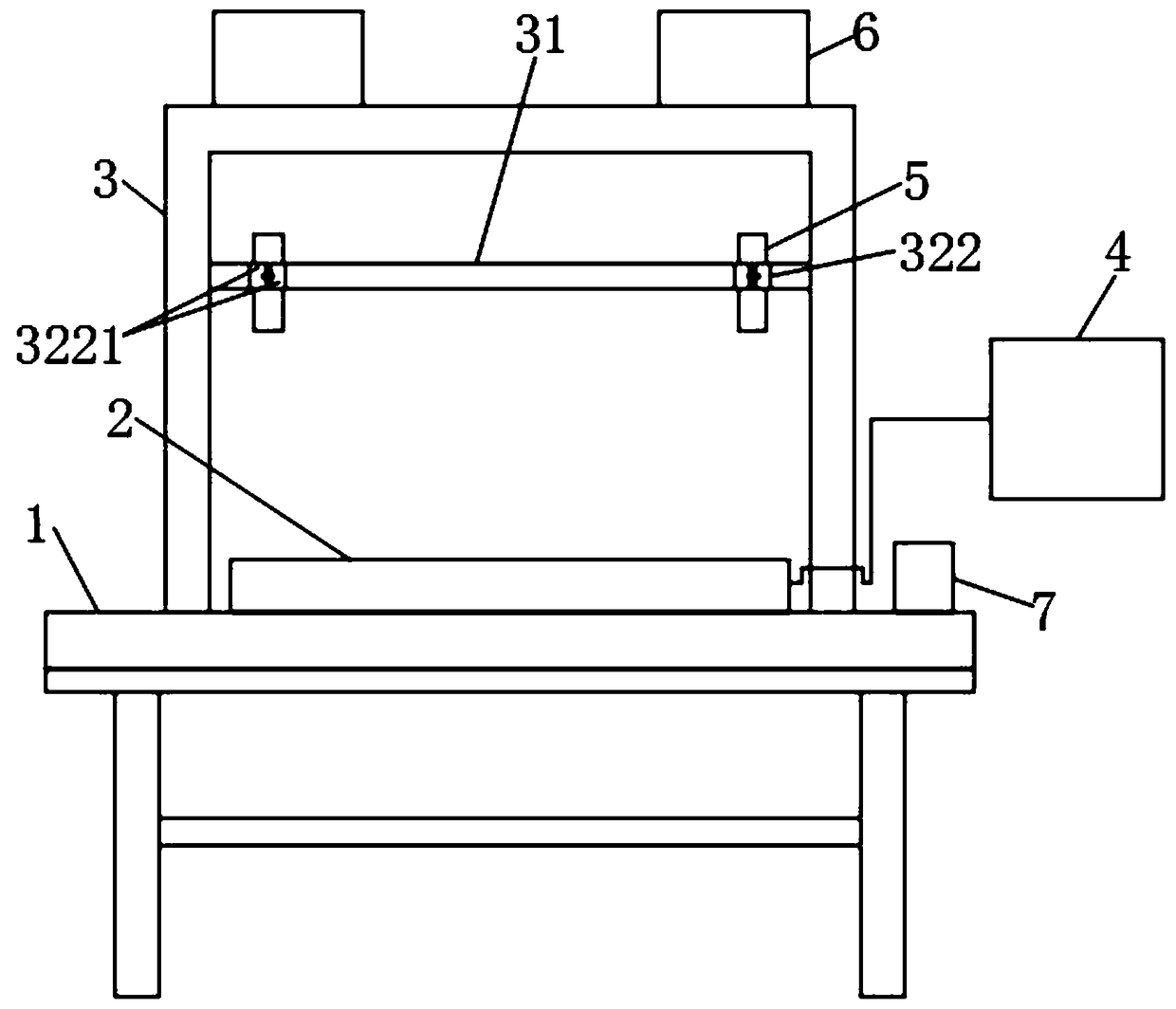

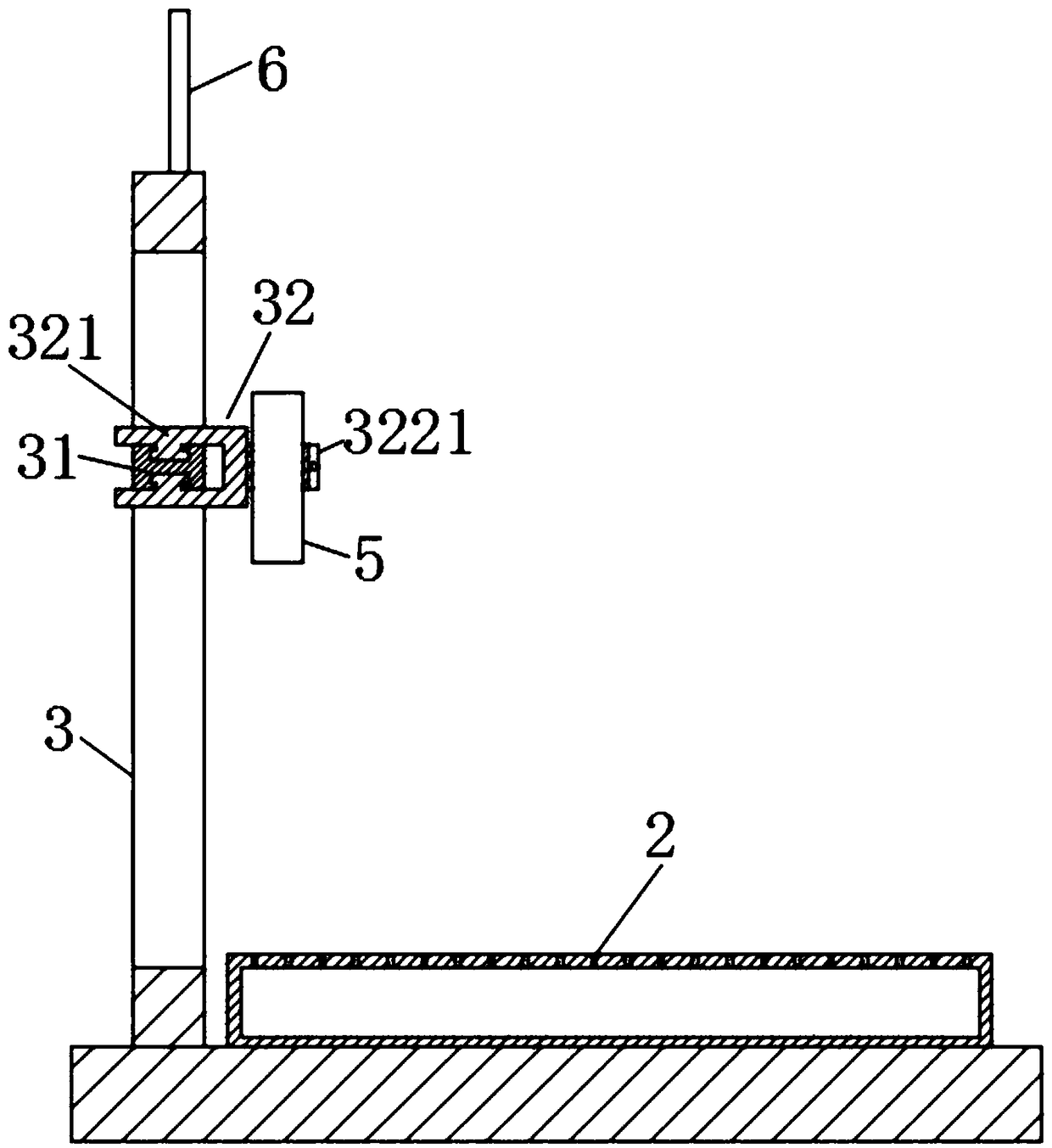

[0029] Example: such as Figures 1 to 3 As shown, the alignment bonding machine for liquid crystal glass sheets of this embodiment is used to align two rectangular liquid crystal glass sheets with the same specifications and stacked up and down. It is characterized in that it includes a workbench 1, an alignment platform 2, a support 3. Two sets of cameras 5, two sets of display screens 6 and negative pressure generating device 4;

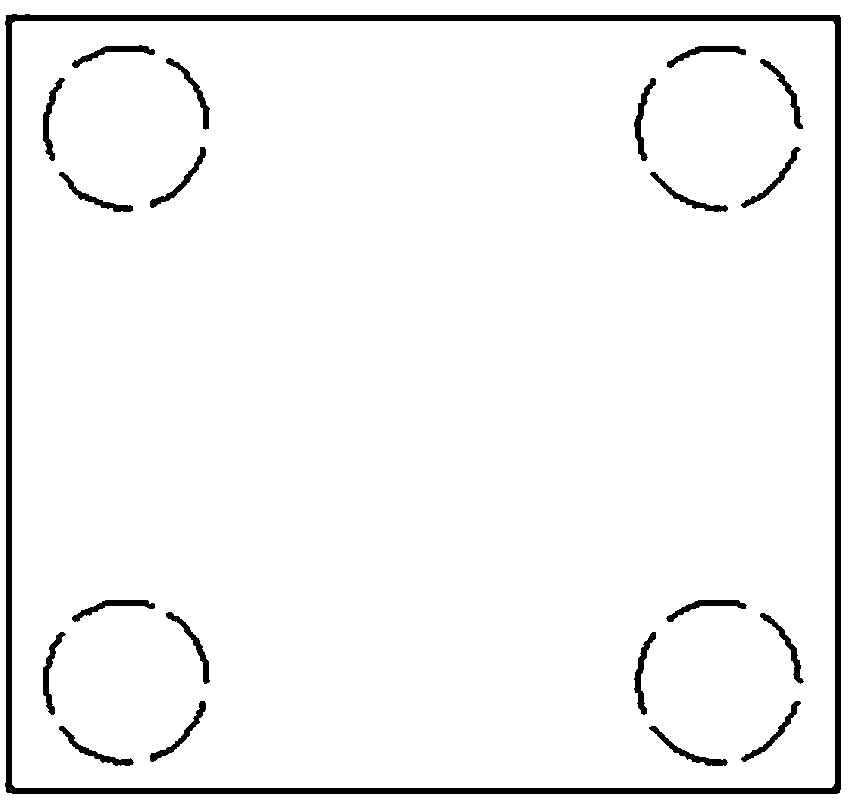

[0030] The above-mentioned workbench 1 is arranged horizontally, and the above-mentioned alignment platform 2 is horizontally installed on the above-mentioned workbench 1. The interior of the above-mentioned alignment platform 2 is hollow and has a plurality of adsorption holes connected to the inside of the above-mentioned alignment platform. The road is internally connected with the above-mentioned alignment platform 2;

[0031] The above-mentioned bracket 3 is installed on the above-mentioned workbench 1 and is located on the side of the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com