A single-sided transfer type graphene film structure and a preparation method thereof

A graphene film and graphene layer technology, which is applied in cable/conductor manufacturing, electrical components, conductive layers on insulating carriers, etc., can solve the problems of complicated procedures, high production costs, complicated preparation methods, etc., and achieves a simple production method. , enhance the electrical conductivity, enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

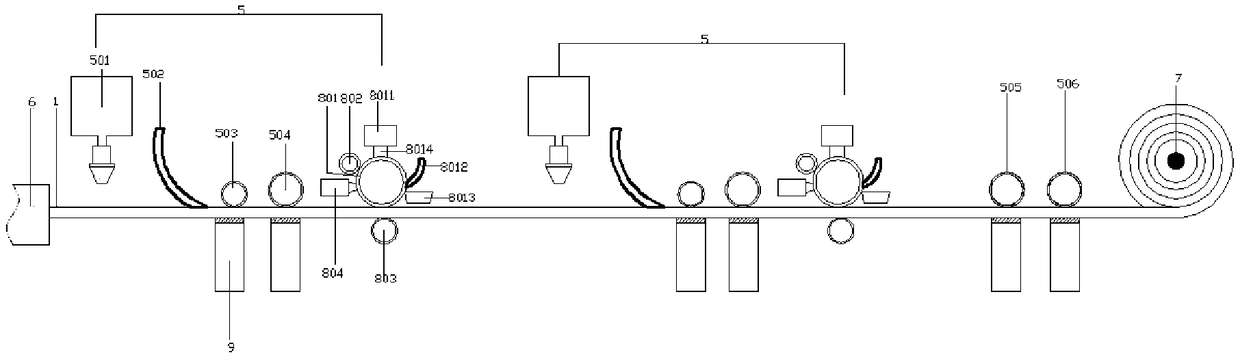

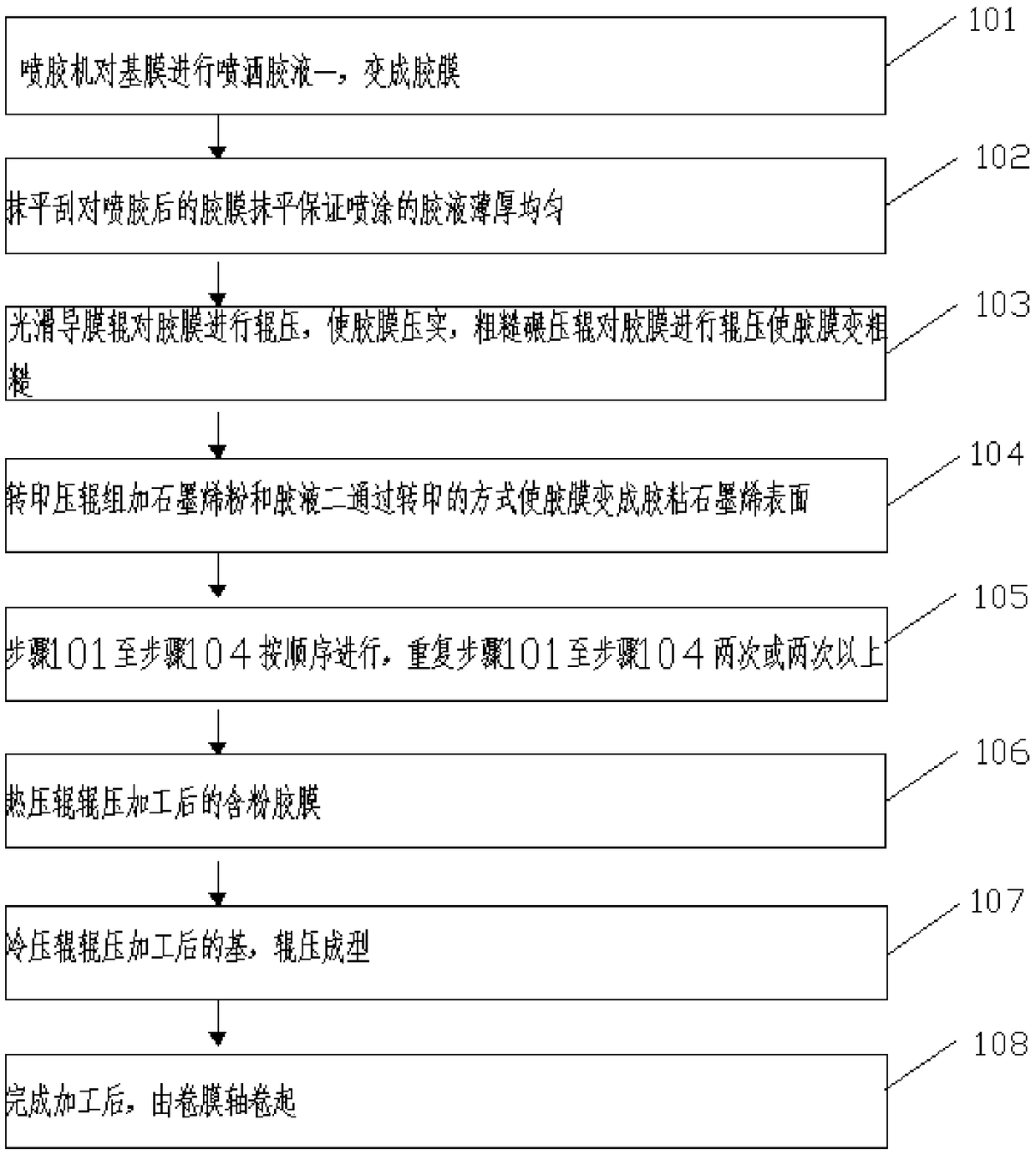

[0050] A kind of preparation method of single-sided transfer type graphene membrane, described graphene membrane comprises following preparation method by:

[0051] Step 101: The glue sprayer 501 sprays the glue solution 1 on the base film 2 to form a glue film;

[0052] Step 102: Squeegee 502 to smooth the adhesive film after glue spraying to ensure that the thickness of the sprayed glue is uniform;

[0053] Step 103: the smooth film guide roller 503 rolls the film to make the film compact, and the rough rolling roller 502 rolls the film to make the film rough;

[0054] Step 104: Adding graphene powder and glue solution 2 to the transfer press roller group 8 to make the adhesive film become an adhesive graphene surface by means of transfer printing;

[0055] Step 105: Steps 1 to 4 are performed in sequence, and steps 1 to 4 are repeated two or more times;

[0056] Step 106: hot pressing roller 505 rolls the processed base film 2;

[0057] Step 107: The base film 2 processe...

specific Embodiment

[0064] In actual use, the base film 2 is sent out through the film outlet 6, the glue sprayer 501 sprays the glue solution 1 on the base film 2 to make it into a film, and the smoothing scraper 502 smoothes the sprayed film Ensure that the thickness of the sprayed glue is uniform, the smooth film guide roller 503 rolls the film to make the film compact, the rough rolling roller 502 rolls the film to make the film rough, and the transfer roller set 8 plus Graphene powder and glue solution 2 make the adhesive film become an adhesive graphene surface by transfer printing, repeat the above steps twice, continue to spray glue solution 1, continue to smooth, continue to roll, continue to transfer and roll, increase Adhesion effect, effectively prevent the glue and graphene powder from peeling off, and greatly enhance the electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com