LED driving power supply and working method thereof, and LED lamp

A technology of LED drive and power supply, applied in the field of chargers and LED lighting, can solve the problems of poor anti-surge ability, poor reliability, grid interference, etc., and achieve the effect of convenient expansion, lifespan and reliability advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

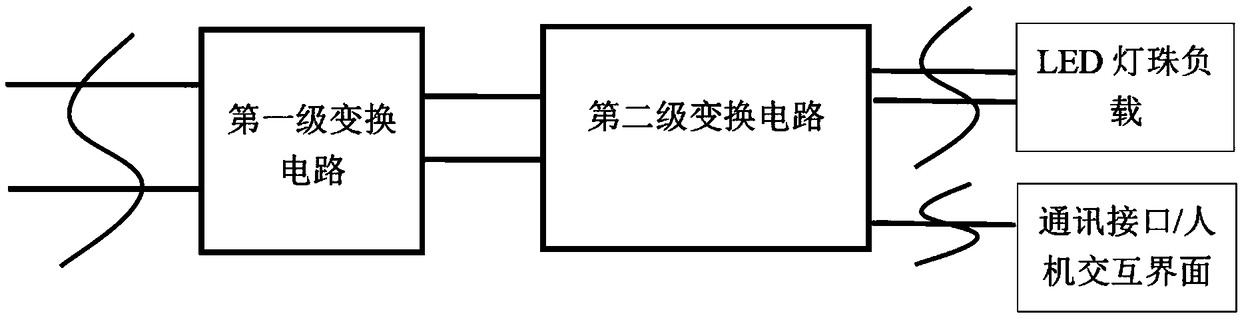

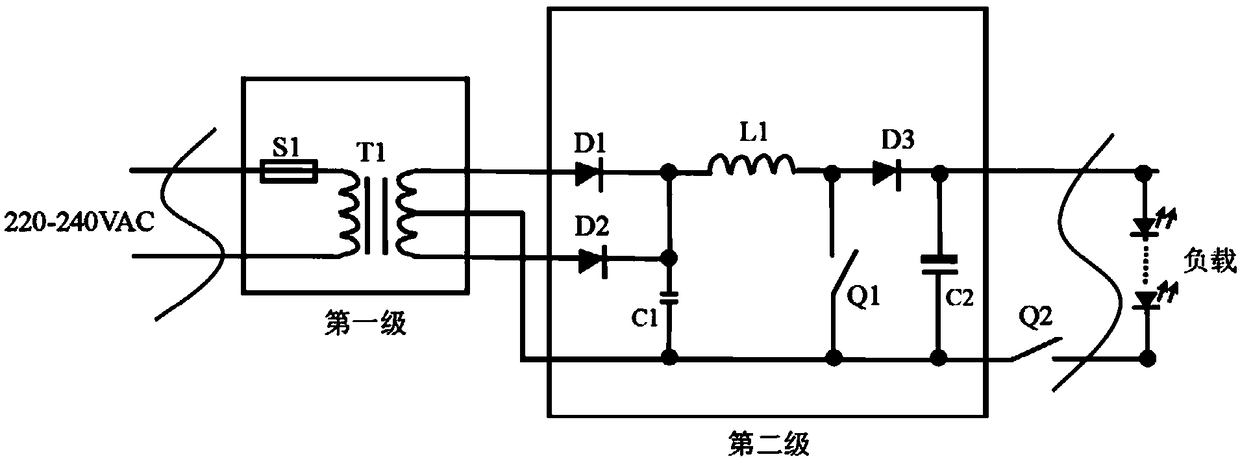

[0043] Such as figure 1 , 2 , the realization idea of LED drive power supply is as follows:

[0044] (1) The entire topology is divided into two levels, such as figure 1 .

[0045] Among them, the first-stage conversion circuit adopts a power frequency transformer to convert the mains high-voltage AC into low-voltage AC. The output AC voltage of the first stage is generally 12VAC ~ 48VAC to meet the requirements of SELV (Safety extra lowvoltage) in IEC 61558 . Generally, a fuse or a self-recoverable fuse can also be added to the primary side of the power frequency transformer to provide self-protection capability under abnormal conditions.

[0046] The power frequency transformer used in this stage has the characteristics of inductive impedance on the primary side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com