Sphagnum solidified fiber soil and preparation method and application thereof

A technology for curing fibers and water moss, which is applied in the field of greening, can solve the problems of inability to be widely used, high cost, and limited application range, etc., and achieve excellent greening effect, good molding degree, and reduce engineering and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

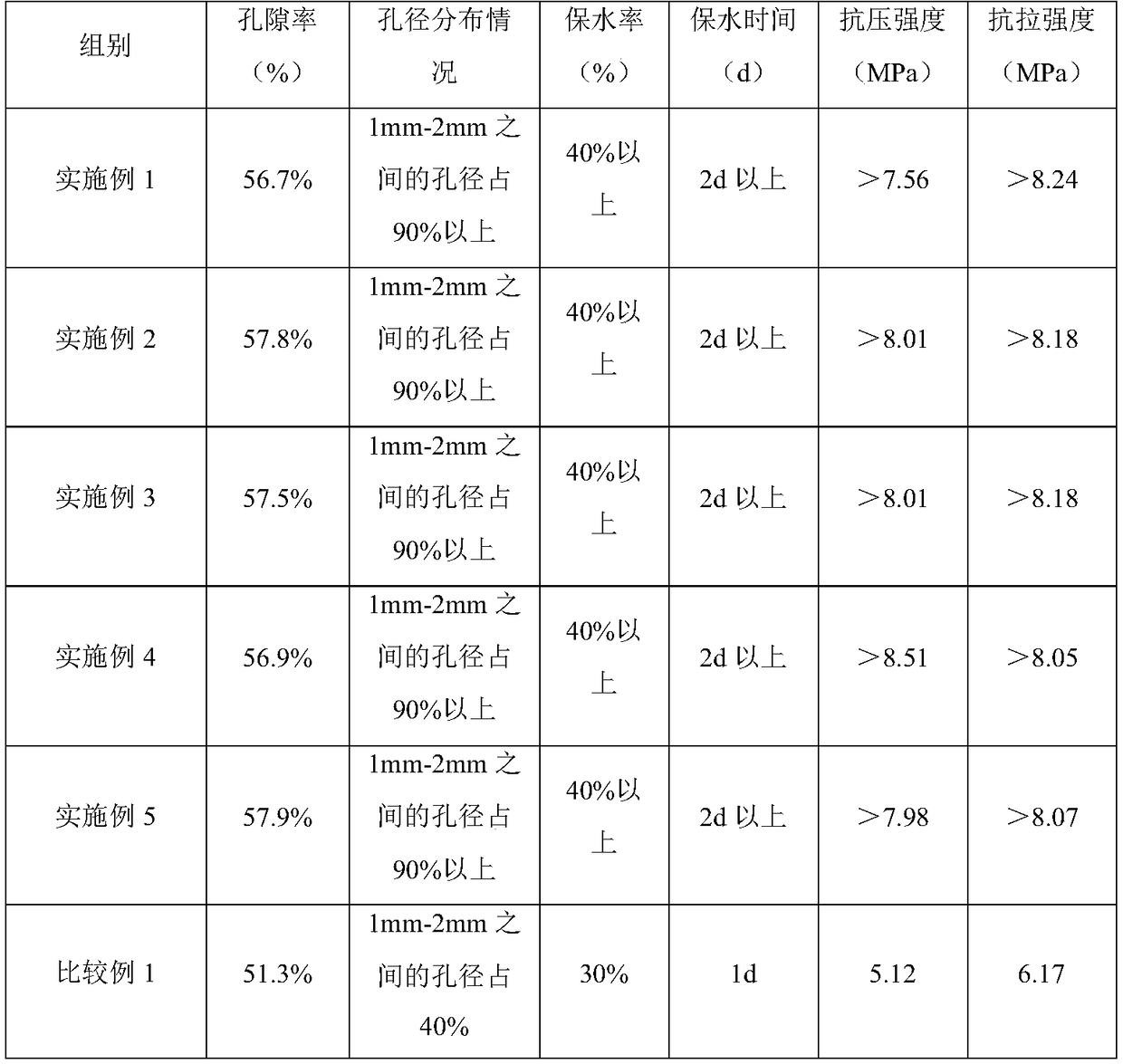

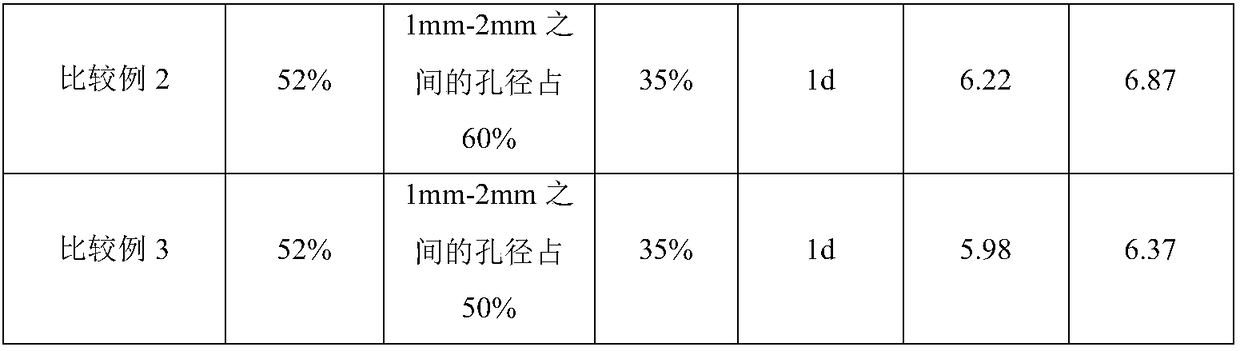

Examples

Embodiment 1

[0035] The preparation method of sphagnum solidified fiber soil is carried out according to the following steps:

[0036] 1) Weigh according to the following quality: 12kg of sphagnum moss, 15kg of coconut peat, 2kg of fiber cotton, 8kg of perlite, 11kg of vermiculite, 30kg of peat soil, 7kg of gypsum powder, 3kg of talcum powder, and 4kg of pine fiber;

[0037] 2) Mix the above 9 kinds of raw materials according to the above formula, and use a drum mixer to stir at high temperature for 20 minutes to prepare a uniform sphagnum fiber soil dispersion;

[0038] 3) Take out the uniform sphagnum fiber soil powder, place it in a 40°C steamer box for autoclaving, melting and bonding, and prepare a viscous warm object with a water content of 6%;

[0039] 4) With a weight of 1.5kg, place the viscous warm object in a tray with a length, width and height of 560mm×280mm×80mm, cool it, and press film to form;

[0040] 5) Select a convex mold plate with a length, width and height of 560mm×28...

Embodiment 2

[0046] The preparation method of sphagnum-solidified fiber soil is carried out according to the following steps:

[0047] 1) Weigh according to the following quality: Guizhou sphagnum moss 17kg, Hainan coconut peat 10kg, fiber cotton 7kg, perlite 13kg, vermiculite 6kg, peat soil 40kg, gypsum powder 2kg, talc powder 4kg, pine fiber 8kg;

[0048] 2) Select the top-quality Guizhou sphagnum moss and place it in a dry state with a moisture content of about 1.5%, use an ordinary pulverizer to stir, grind the Guizhou sphagnum moss into a 3-5cm long fiber-shaped object, and prepare general-purpose cured coconut peat. Coconut peat whose wool fiber length is between 2-5cm is selected from waste leftovers in cotton textile mills, and is squeezed twice through a machine to crush it into a lint-free fiber-like material with a length of 1-3cm. And screen the perlite with microparticle diameter between 0.2-0.3cm and the vermiculite with microparticle diameter between 0.3-0.5cm, choose the fr...

Embodiment 3

[0058] The specific operation method is basically the same as in Example 2, except that the raw materials are weighed according to the following quality: 13kg of Guizhou sphagnum moss, 14kg of Hainan coconut peat, 3kg of fiber cotton, 12kg of perlite, 7kg of vermiculite, 32kg of peat soil, 6kg of gypsum powder, and talc Powder 3.2kg, pine branch fiber 7kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com