Device for drying cereals in sun

A grain and equipment technology, which is applied in the field of equipment for drying grain, can solve the problems of heavy labor burden, inconvenience for people, easy microscopic cracks on the surface of grain, etc., and achieve the effect of reducing labor load and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

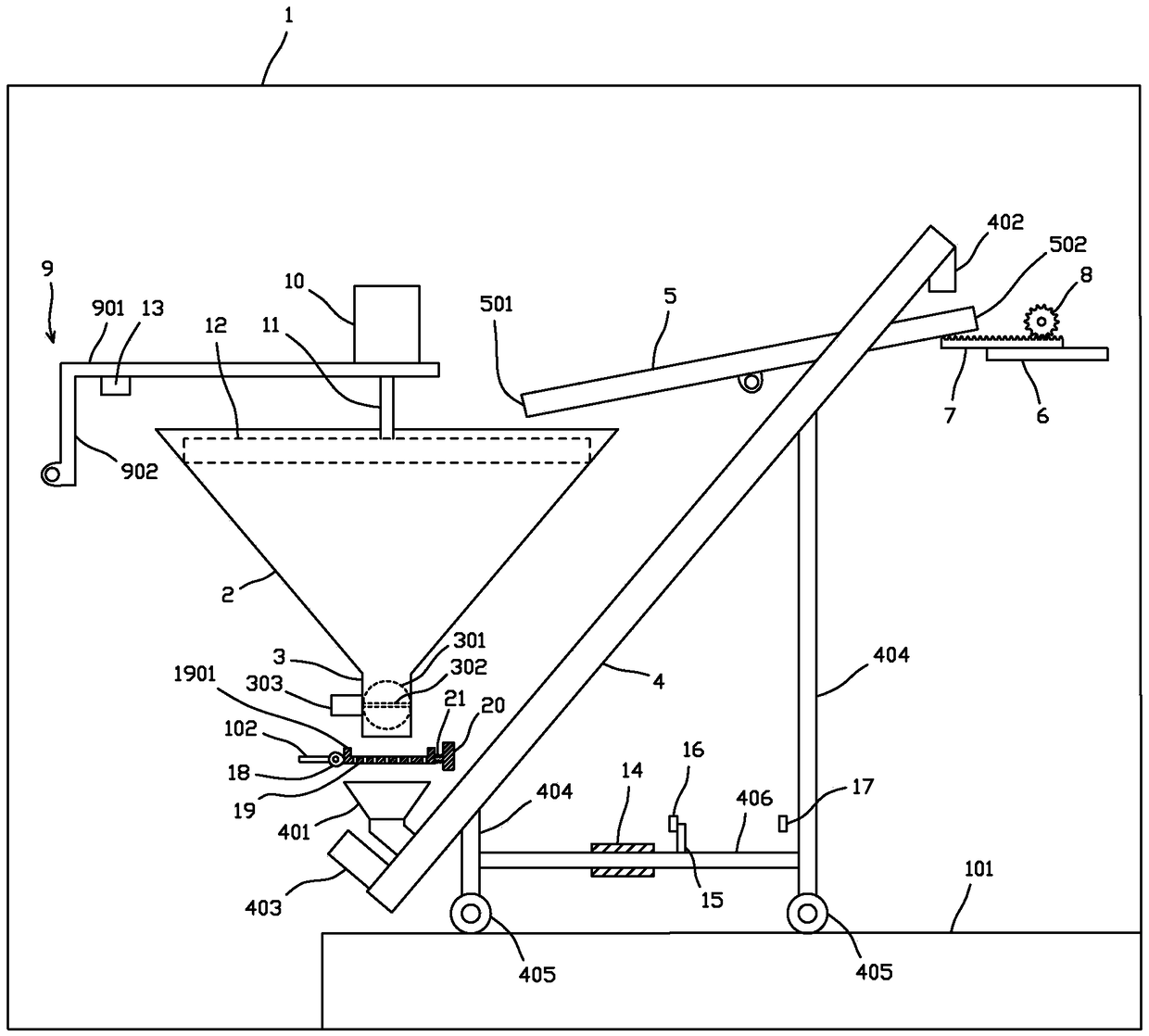

[0027] figure 1 Among them, the inclined screw conveyor 4 is in the first position, the feeding trough 5 is in the first state, and the mounting plate 9 is in the first state.

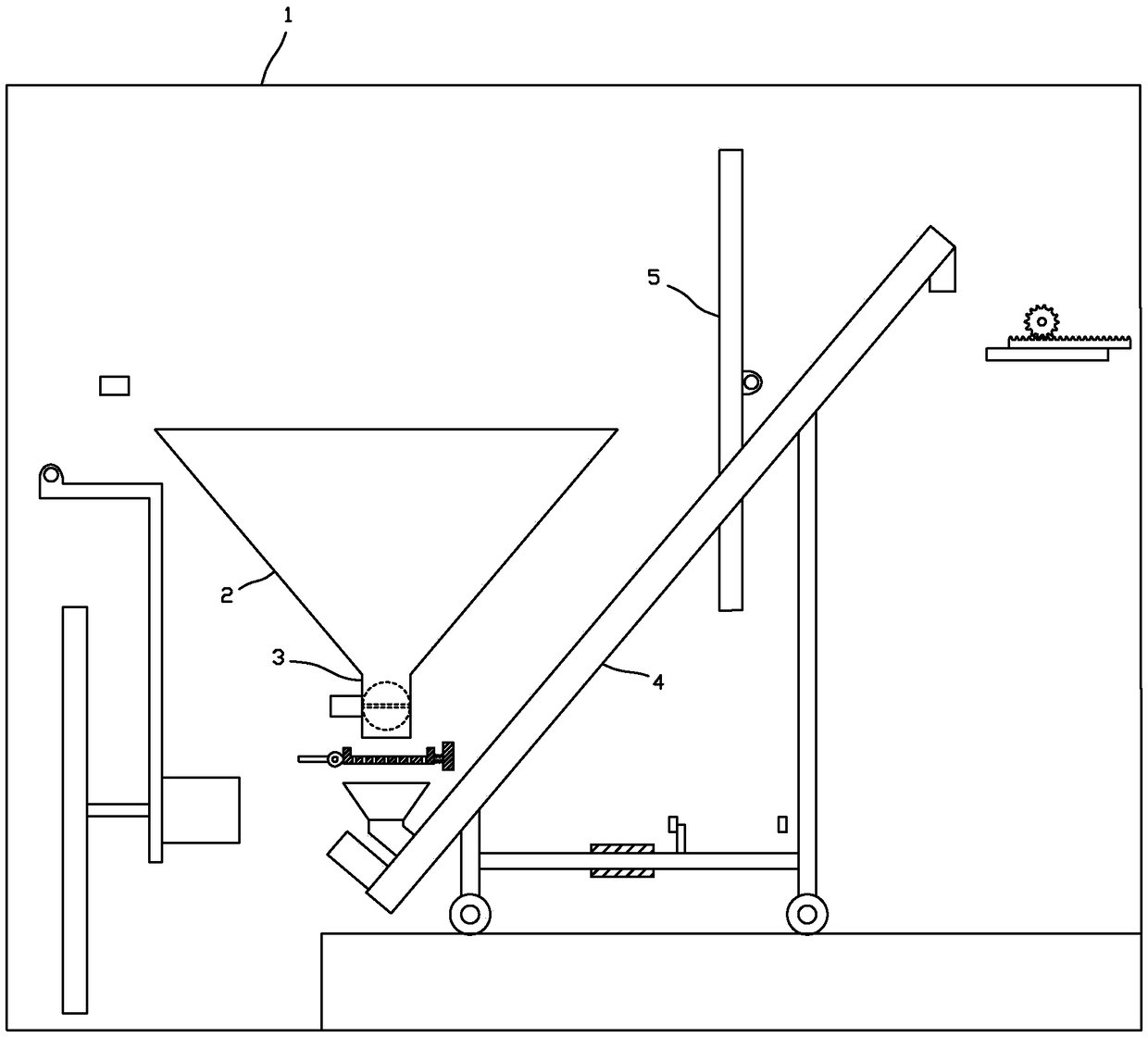

[0028] figure 2 Among them, the inclined screw conveyor 4 is in the first position, the feeding trough 5 is in the second state, and the mounting plate 9 is in the second state.

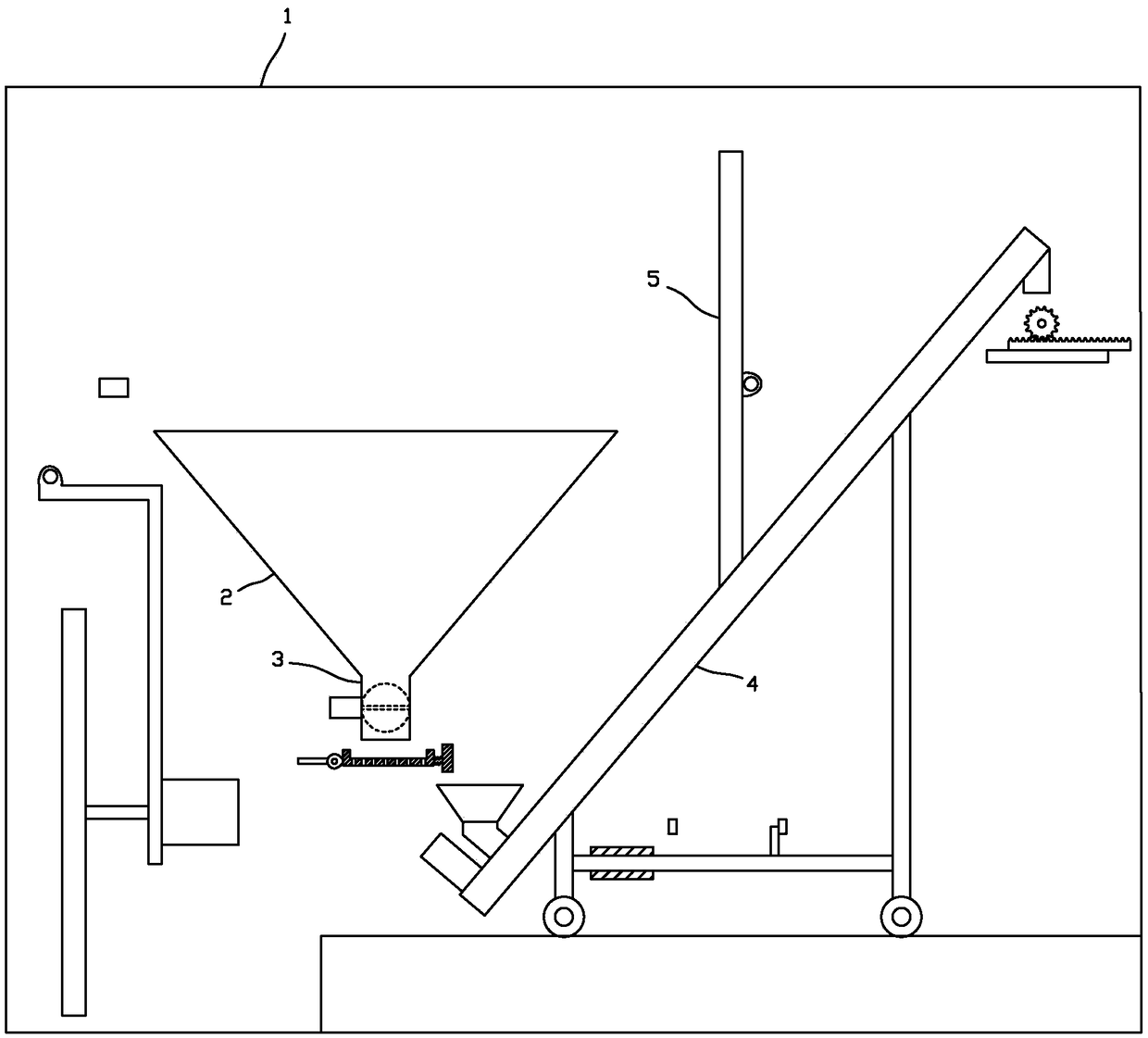

[0029] image 3 Among them, the inclined screw conveyor 4 is in the second position, the feeding trough 5 is in the second state, and the mounting plate 9 is in the second state.

[0030] Depend on Figure 1-Figure 6 As shown, the present invention is used for the equipment that grain is carried out to dry and comprises a frame 1, and frame 1 is provided with a material cylinder 2 for holding grain, and material cylinder 2 is placed horizontally, and material cylinder 2 is big up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap