High-calcium gristle pork plate and manufacture method thereof

A technology of pork and crispy bones, which is applied in the direction of meat/fish preservation, food ingredients as emulsifiers, meat/fish preserved by freezing/cooling, etc. It can solve the problem of affecting the taste and appetite of users, rarely directly eating pork crispy bones, The patient is not easy to chew and other problems, and achieves the effect of reducing the probability of fracture, unique taste and distinct layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

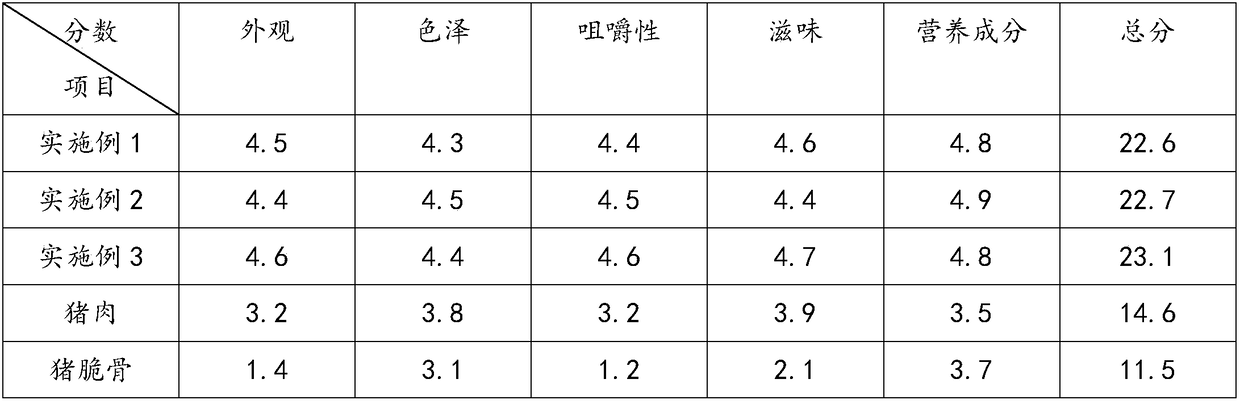

Embodiment 1

[0034] A high-calcium crispy pork plate, characterized in that the raw material formula is as follows: 75 parts by weight of pork, 25 parts by weight of pork crispy bones, 2.5 parts by weight of soybean protein, 2.5 parts by weight of edible salt, 1.5 parts by weight of white sugar, and 1.5 parts by weight of konjac powder , 0.01 parts by weight of food additives, 0.01 parts by weight of edible flavors and fragrances, 0.015 parts by weight of compound emulsifiers, and 0.5 parts by weight of water.

[0035] Specifically, the pork brittle bones are pork brittle bones with pork, wherein the ratio of pork to brittle bones is 2:8, and the particle size of the pork brittle bones is 0.5 cm.

[0036] A kind of preparation method of high-calcium brittle pork plate, is characterized in that, concrete steps are as follows:

[0037](1) Pork segmentation: select fresh pork, remove the congestion, broken bones and pig hairs in the pork, and divide the pork into 5cm×5cm×0.3cm slices to obtai...

Embodiment 2

[0047] A high-calcium crispy pork plate, characterized in that the raw material formula is as follows: 85 parts by weight of pork, 15 parts by weight of pork crispy bones, 3 parts by weight of soybean protein, 3 parts by weight of edible salt, 2 parts by weight of white sugar, and 2 parts by weight of konjac powder , 0.02 parts by weight of food additives, 0.02 parts by weight of edible flavors and fragrances, 0.02 parts by weight of compound emulsifiers, and 0.8 parts by weight of water.

[0048] Specifically, the pork brittle bones are pork brittle bones with pork, wherein the ratio of pork to brittle bones is 2:8, and the particle size of the pork brittle bones is 0.5 cm.

[0049] A kind of preparation method of high-calcium brittle pork plate, is characterized in that, concrete steps are as follows:

[0050] (1) Pork segmentation: select fresh pork, remove the congestion, broken bones and pig hairs in the pork, and divide the pork into 5cm×5cm×0.3cm slices to obtain sliced...

Embodiment 3

[0060] A high-calcium crispy pork plate, characterized in that the raw material formula is as follows: 90 parts by weight of pork, 20 parts by weight of pork crispy bones, 3.5 parts by weight of soybean protein, 3.5 parts by weight of edible salt, 2.5 parts by weight of white sugar, and 2.5 parts by weight of konjac powder , 0.04 parts by weight of food additives, 0.04 parts by weight of food flavors and fragrances, 0.025 parts by weight of compound emulsifier, and 1 part by weight of water.

[0061] Specifically, the pork brittle bones are pork brittle bones with pork, wherein the ratio of pork to brittle bones is 2:8, and the particle size of the pork brittle bones is 0.5 cm.

[0062] A kind of preparation method of high-calcium brittle pork plate, is characterized in that, concrete steps are as follows:

[0063] (1) Pork segmentation: select fresh pork, remove the congestion, broken bones and pig hairs in the pork, and divide the pork into 5cm×5cm×0.3cm slices to obtain sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com