Carpet cleaning machine

A carpet cleaning machine and trigger technology, applied in the field of cleaning tools, can solve the problems of long distance between the floor brush assembly and the handle, difficult to see whether it is clean, and high center of gravity of the carpet cleaning machine, so as to improve the convenience of operation and the ability to raise dust on the side. and drying ability, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

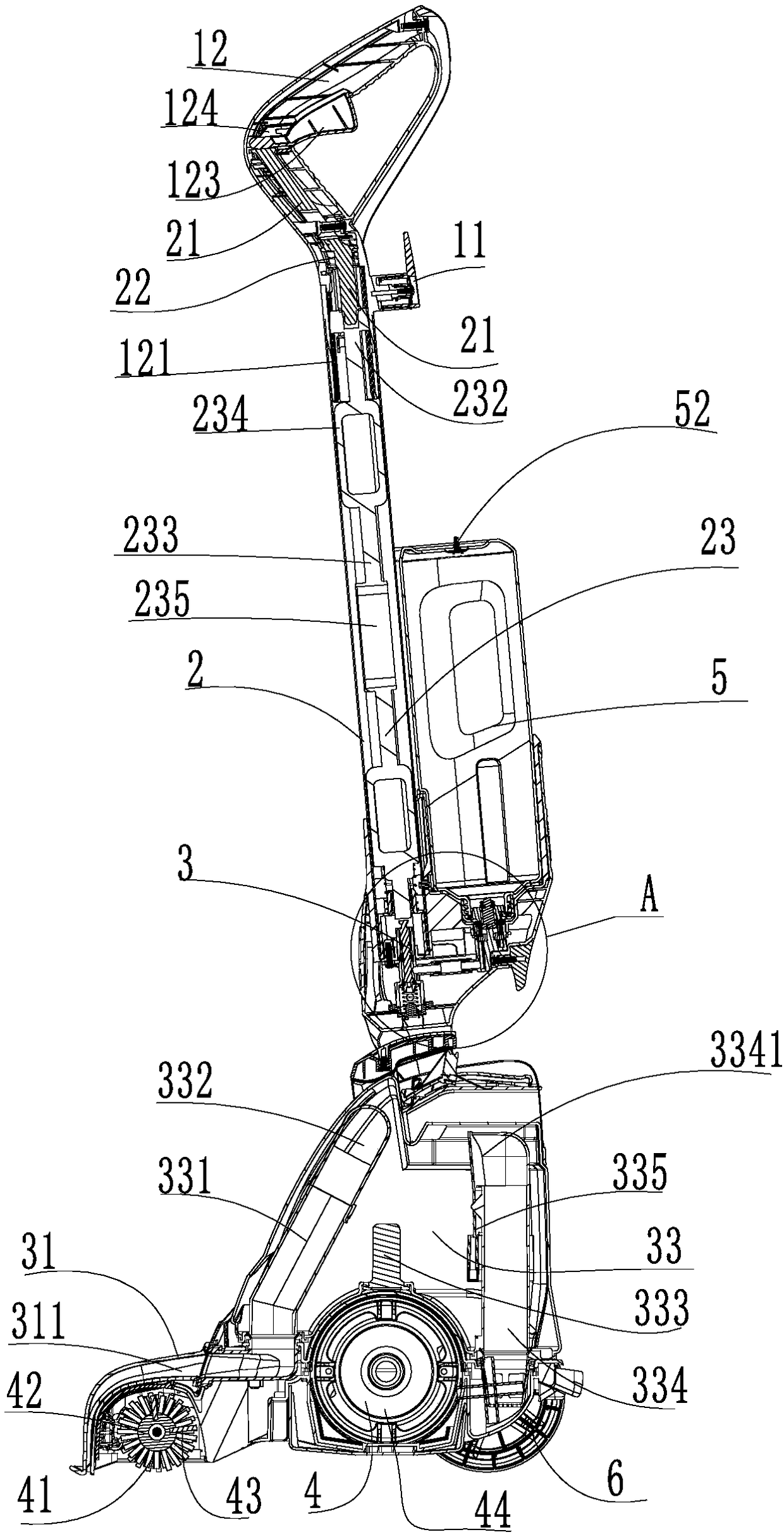

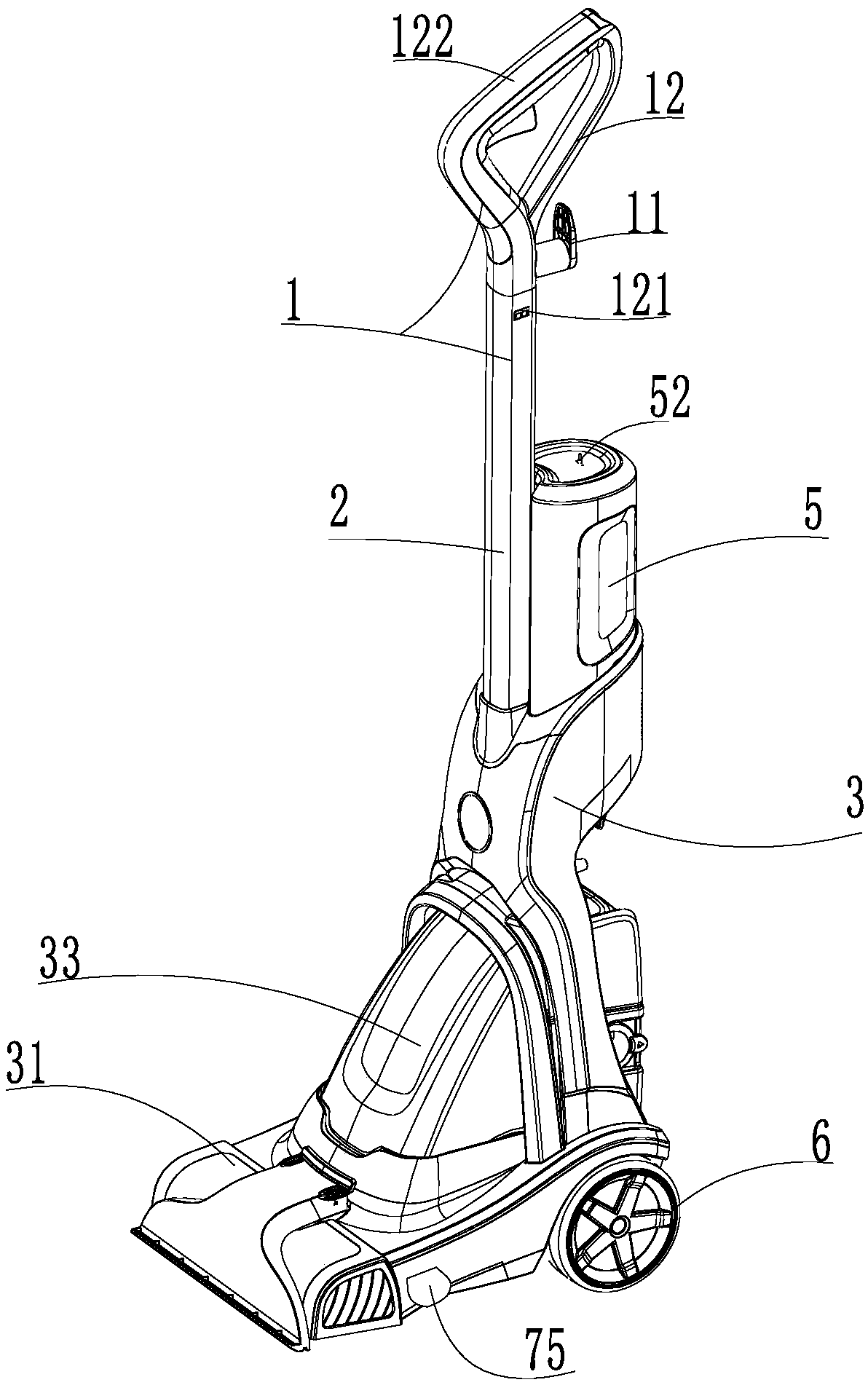

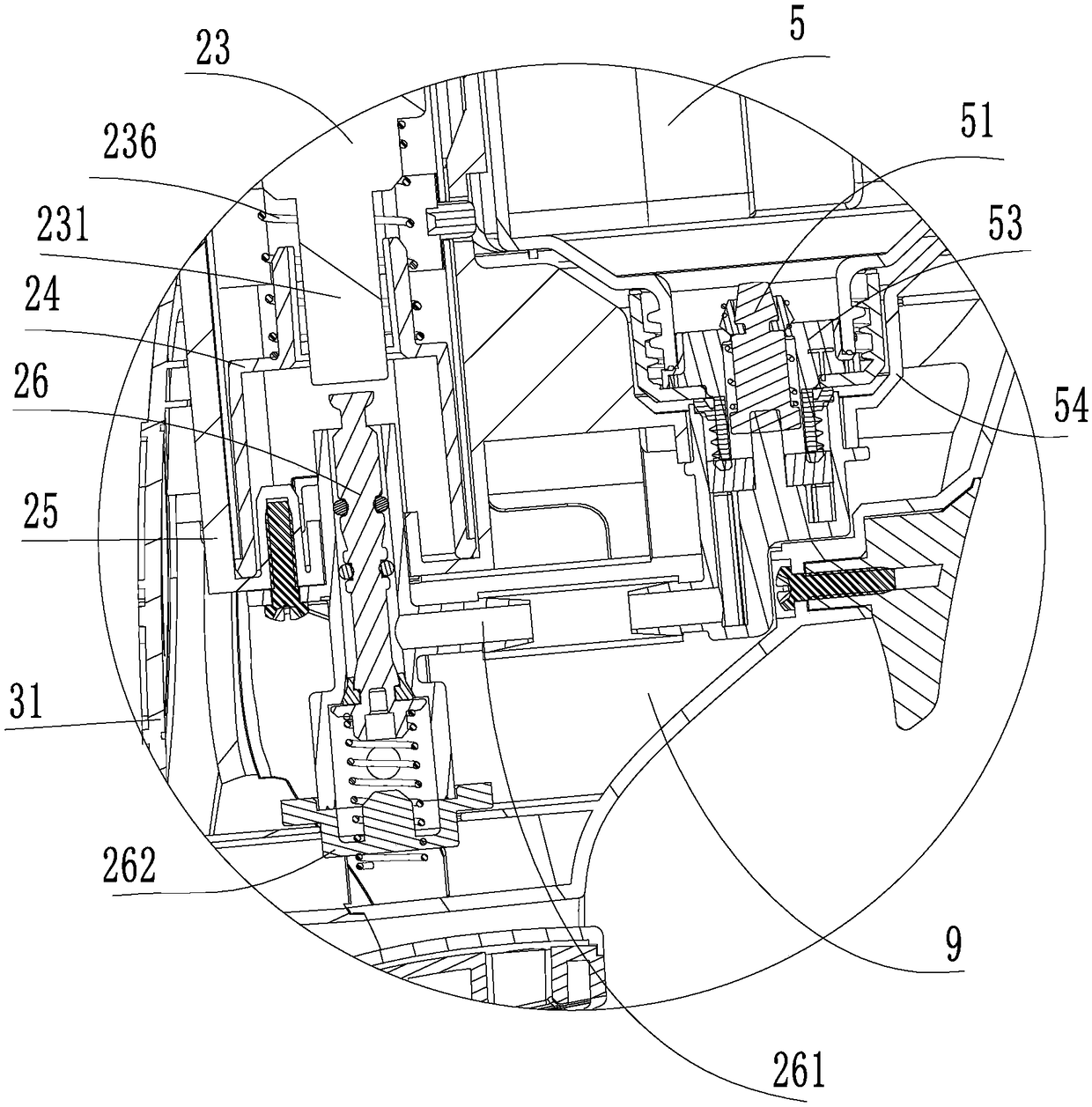

[0035] Figure 1 to Figure 8Among them, a carpet cleaning machine includes a handle assembly 1, a fuselage assembly 3 and a mopping assembly 4 arranged in sequence from top to bottom; machine 44, the housing 31 includes an upper housing 301 and a lower housing 302, the exhaust fan 44 is located between the upper housing 301 and the lower housing 302, the lower side of the housing 31 is provided with a water absorption chamber 311, and the water absorption chamber 311 is located in the lower housing Inside the body 302, the rolling brush 41 is installed in the water suction chamber 311. The machine shaft of blower fan 44 and roller brush 41 ends can be connected by transmission belt 45 and belt 45 wheels, and blower fan 44 drives roller brush 41 to rotate when energizing and rotates, and produces the cleaning and the water absorption of wind po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com