Racing track spraying structure and racing track spraying molding method

A technology of injection molding and track, which is applied in the direction of building construction, sports accessories, binding of skis, etc., can solve the problems of inability to guarantee compactness, strength, radian, flatness, etc., and achieve surface curvature control and leveling , improve the compactness, improve the effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

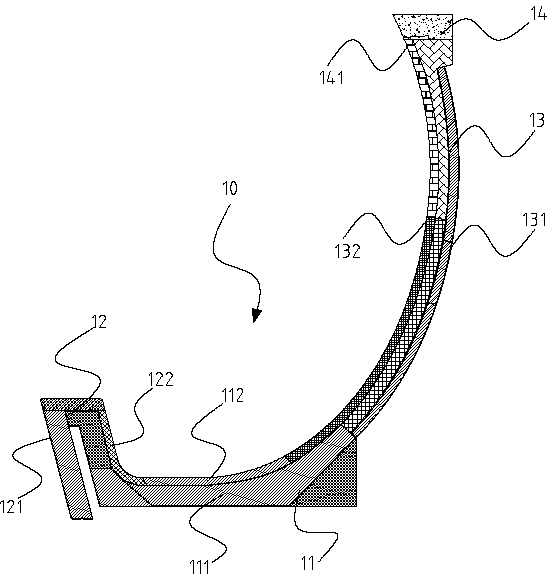

[0026] Such as figure 1 As shown, the present embodiment provides a track spraying structure for spraying concrete on the track 10, including the bottom 11 of the track 10, the lower cornice 12 connected to one end of the bottom 11, and the other end of the bottom 11. A high wall 13 connected at one end and an upper cornice 14 connected with the high wall 13, wherein the bottom 11 of the race track 10 is laid with a first template 111, a first steel bar on the first template 111 and a The first leveling pipe 112 on the first steel bar, the lower eaves 12 of the track 10 are laid with a second formwork 121, a second steel bar on the second formwork 121 and a second steel bar on the second steel bar. The second leveling pipe 122 of the track 10, the high wall 13 of the race track 10 is sequentially laid with a non-dismantling mesh 131, a third steel bar on the non-dismantling mesh 131, and a third leveling on the third steel bar. pipe 132, the upper cornice 14 of the track 10 i...

Embodiment 2

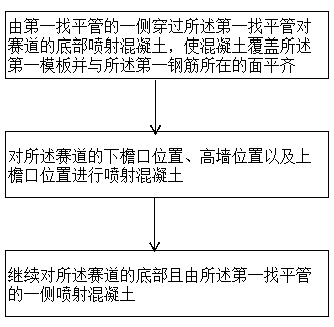

[0030] Such as figure 1 with figure 2 As shown, this embodiment provides a race track injection molding method, using the race track injection structure described in Embodiment 1 to spray concrete on the race track, which includes the following steps: Step S1: by the first leveling pipe 112 One side passes through the first leveling pipe 112 to spray concrete on the bottom 11 of the track 10, so that the concrete covers the first template 111 and is flush with the surface where the first steel bar is located; Step S2: The lower eaves 12, the high wall 13 and the upper eaves 14 of the track 10 are sprayed with concrete; step S3: continue to spray concrete on the bottom 11 and from the side of the first leveling pipe 112.

[0031] In the racetrack injection molding method described in this embodiment, in step S1, one side of the first leveling pipe 112 passes through the first leveling pipe 112 to spray concrete on the bottom 11 of the racetrack 10, so that Concrete covers th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com