Polymer emulsifier and preparation method thereof

A polymer emulsifier, emulsifier technology, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., to achieve the effect of simple process synthesis, good wrapping effect, and good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

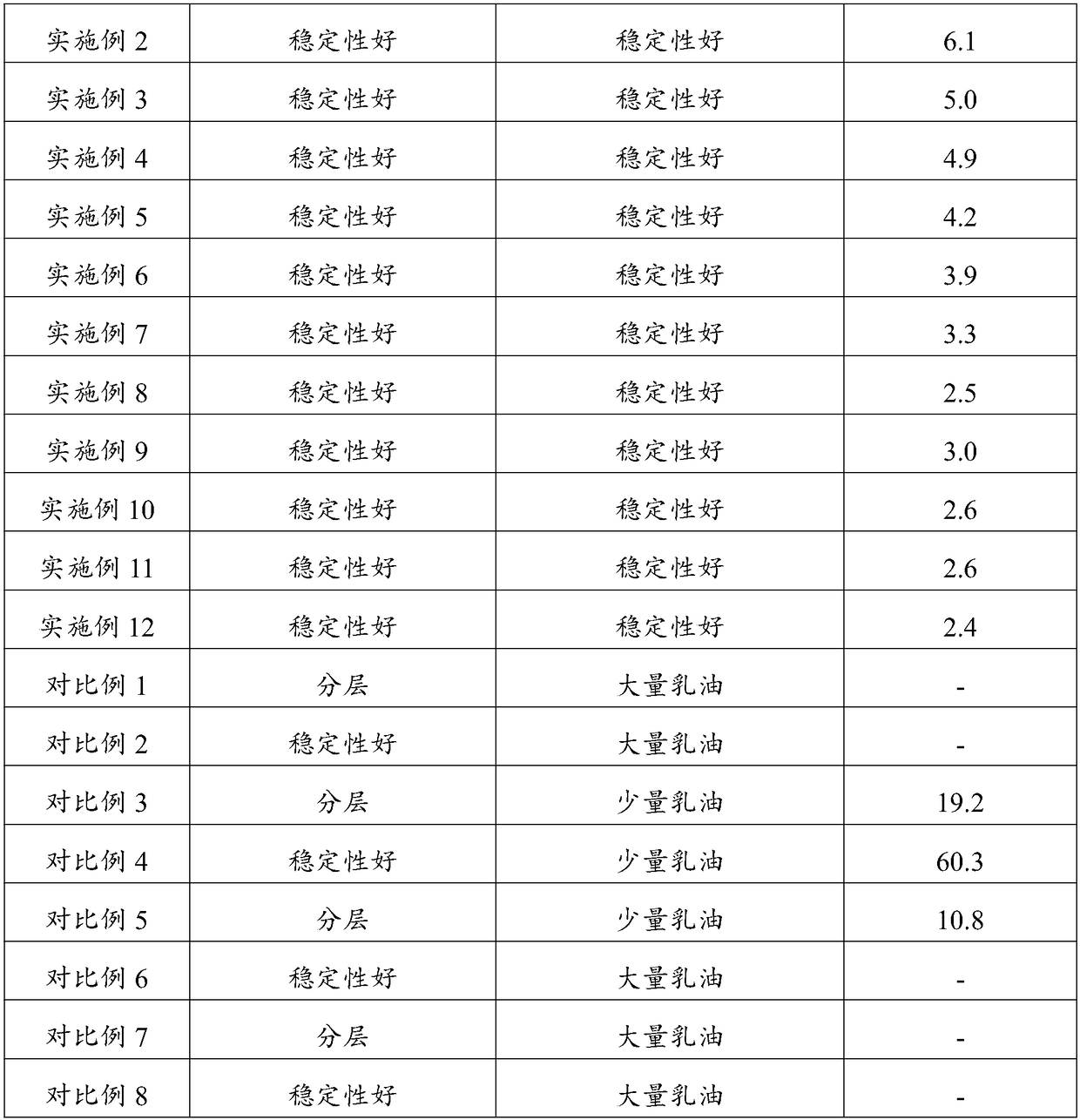

Embodiment 1

[0027] A kind of polymer emulsifier, is made up of following components by weight:

[0028] Acrylic acid 35 parts, stearyl acrylate 35 parts, Pemulen TR-10.5 parts, ammonium persulfate 3 parts, sodium hydroxide 20 parts, water 100 parts.

[0029] Preparation methods include:

[0030] Step 1: Add water, acrylic acid, octadecyl acrylate, Pemulen TR-1, and ammonium persulfate into a reaction kettle equipped with a thermometer, shearing, stirring, and condensing reflux device according to weight, and shear and emulsify for 10 minutes;

[0031] Step 2: The temperature is slowly raised to 90°C and reacted for 4 hours;

[0032] Step 3: Add sodium hydroxide to neutralize, cool and discharge.

[0033] The weight-average relative molecular weight of the polymer emulsifier detected by GPC is 33700.

Embodiment 2

[0035] The stearyl acrylate in Example 1 was replaced with pentyl acrylate, and the others remained unchanged.

[0036] The weight-average relative molecular weight of the polymer emulsifier detected by GPC is 37400.

Embodiment 3

[0038] The octadecyl acrylate in Example 1 was replaced with hexyl methacrylate, and the others were unchanged.

[0039] The weight-average relative molecular weight of the polymer emulsifier detected by GPC is 36500.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap