Special-shaped barrel combined continuous ball mill

A ball mill and cylinder technology, which is applied in the field of special-shaped cylinder combined continuous ball mills, can solve problems such as poor grinding effect, and achieve the effects of less quantity, reduced rotation and improved grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

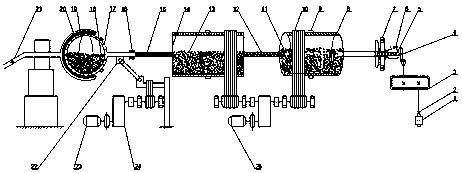

[0030] see figure 1 , figure 2 and image 3 , in the embodiment of the present invention, a special-shaped cylinder combined continuous ball mill, including a first motor 1, the first motor 1 is connected with the first reducer 3 through the coupling 2, the first reducer 3 is connected through the open cone The gear 4 is connected with the screw feeding device 5, and the screw feeding device 5 is connected with the cylinder crushing bin 8 through the feeding end cover 7, and the feeding end cover 7 plays a role of fixing the screw feeding device 5, and the cylindrical The crushing chamber 8 is provided with a crushing chamber grinding body 11 .

Embodiment 2

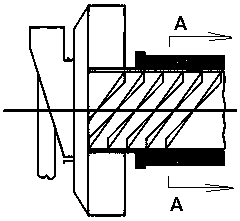

[0032] see figure 1 and Figure 4 , the cylindrical crushing bin 8 is connected to the coarse grinding bin 14 through the first filter screen 12, the cross section of the coarse grinding bin 14 is a regular octagon, and the cylindrical crushing bin 8 and the coarse grinding bin 14 are connected to the first coarse grinding bin 14 through the belt 10 The two motors 23 are connected, and the coarse grinding chamber 14 is provided with a coarse grinding chamber grinding body 13. The coarse grinding chamber 14 adopts a regular octagonal cylinder structure, and its cross section is a regular octagon instead of a circle, which can reduce the rotation to a certain extent. phenomenon, greatly improving the grinding effect; the first filter screen 12 can prevent the crushing chamber grinding body 13 and unground materials from entering the coarse grinding chamber 14 and control the rate at which the ground materials enter the coarse grinding chamber 14.

Embodiment 3

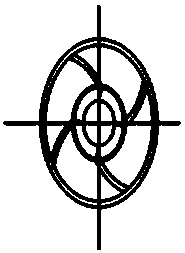

[0034] see figure 1 , the coarse grinding chamber 14 is connected with a plastic flexible hose 16 through the second filter screen 15, the second filter screen 15 can prevent the coarse grinding chamber grinding body 13 and unground material from entering the spherical fine grinding chamber 19 and control the completion of the grinding The rate at which the material enters the spherical fine grinding bin 19, the scalability of the plastic flexible hose 16 can ensure the normal movement of the spherical fine grinding bin 19 when it rotates up and down, left and right; the plastic scalable hose 16 is connected with the spherical fine grinding bin 19. The outer side of the spherical fine grinding chamber 19 is provided with a fine grinding chamber grinding body 18, and the spherical fine grinding chamber 19 is connected with the third motor 25 through the linkage mechanism 22 and the second reducer 24, and the linkage mechanism 22 is connected to the third motor Driven by 25, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com