Die plate for sand casting and vertical casting of flying wheel

A technology of sand casting and vertical casting, which is applied in the direction of casting molding equipment, molds, cores, etc., which can solve the problems of poor reusability, reduced production efficiency, and high precision requirements, so as to reduce self-weight, improve utilization rate, and prevent impurities The effect of entering the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments to facilitate understanding by those skilled in the art.

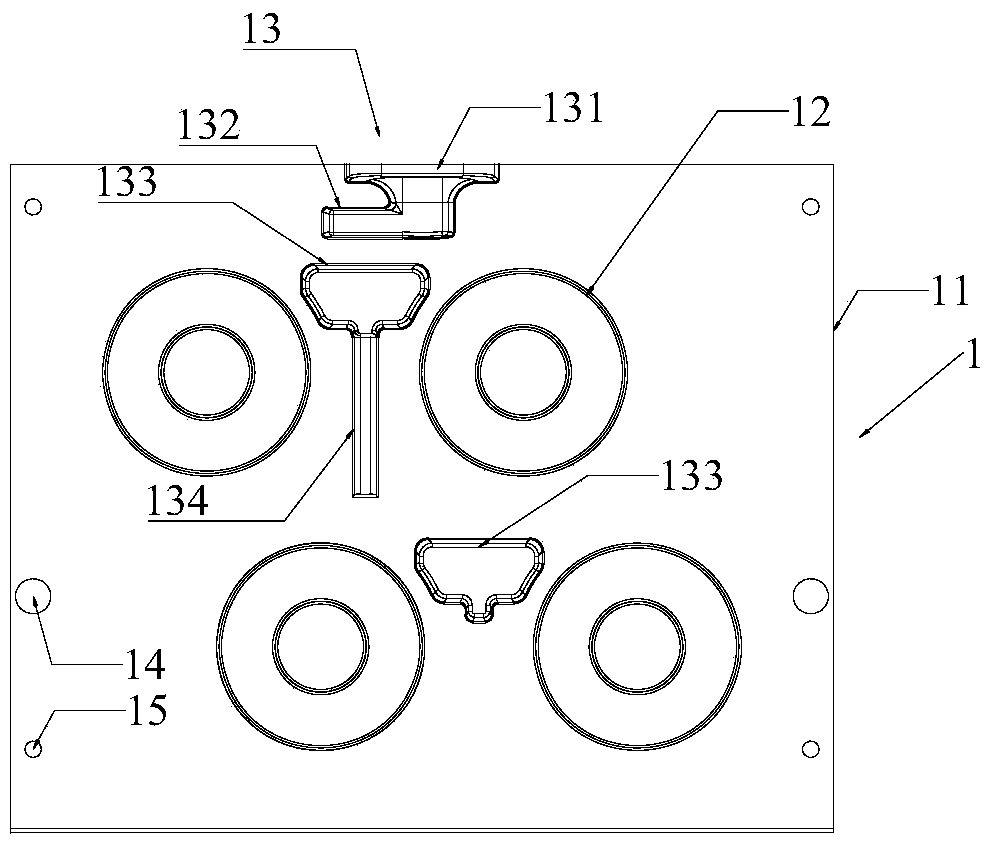

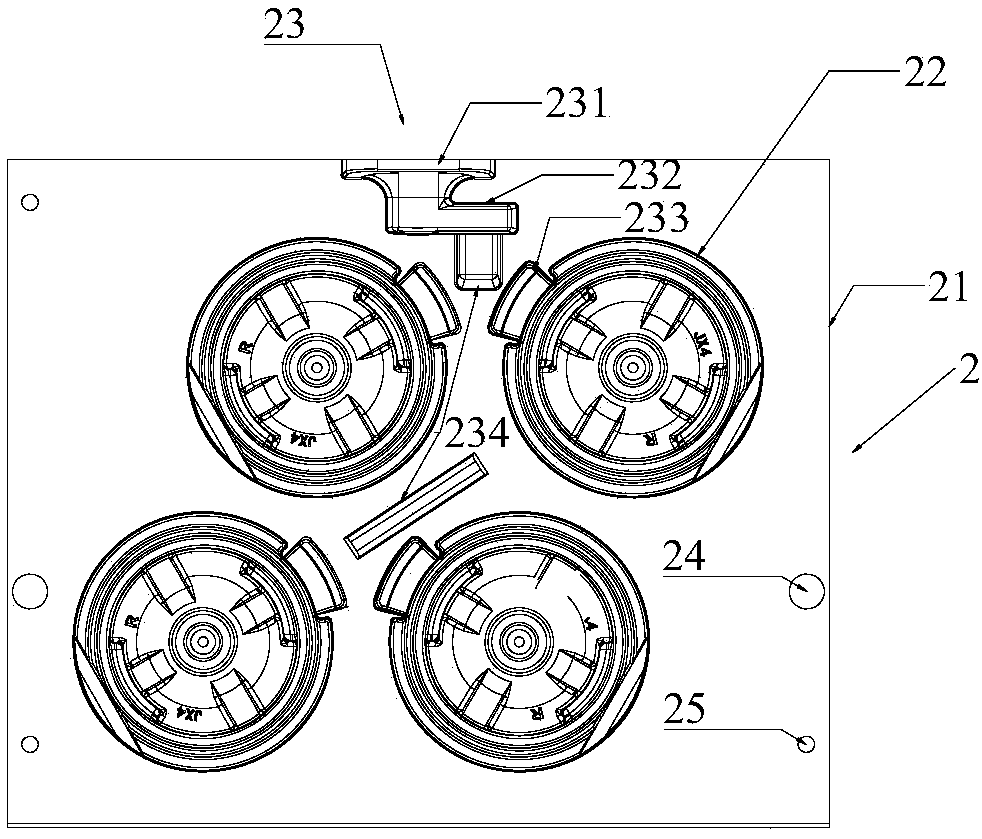

[0028] like Figure 1-2 As shown, the template for vertical casting of flywheel sand casting of the present invention includes a first template 1 and a second template 2, the first template 1 includes a first mold base 11 and is formed on the first mold base 11. The four first casting body patterns 12 and the first pouring pattern 13 on the surface, the second template 2 includes a second mold bottom plate 21 and four second casting body patterns formed on the upper surface of the second mold bottom plate 21 22 and the second casting pattern 23. After the first template 1 and the second template 2 of the present invention are covered with a sand box and filled with sand, a casting cavity, a pouring channel and a riser are formed in the sand mold.

[0029] The four first casting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com