Metal 3D printing machine spraying head device

A 3D printer and print head technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of difficult popularization and application, high cost, complex structure, etc., to achieve improved practicability, cost saving, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

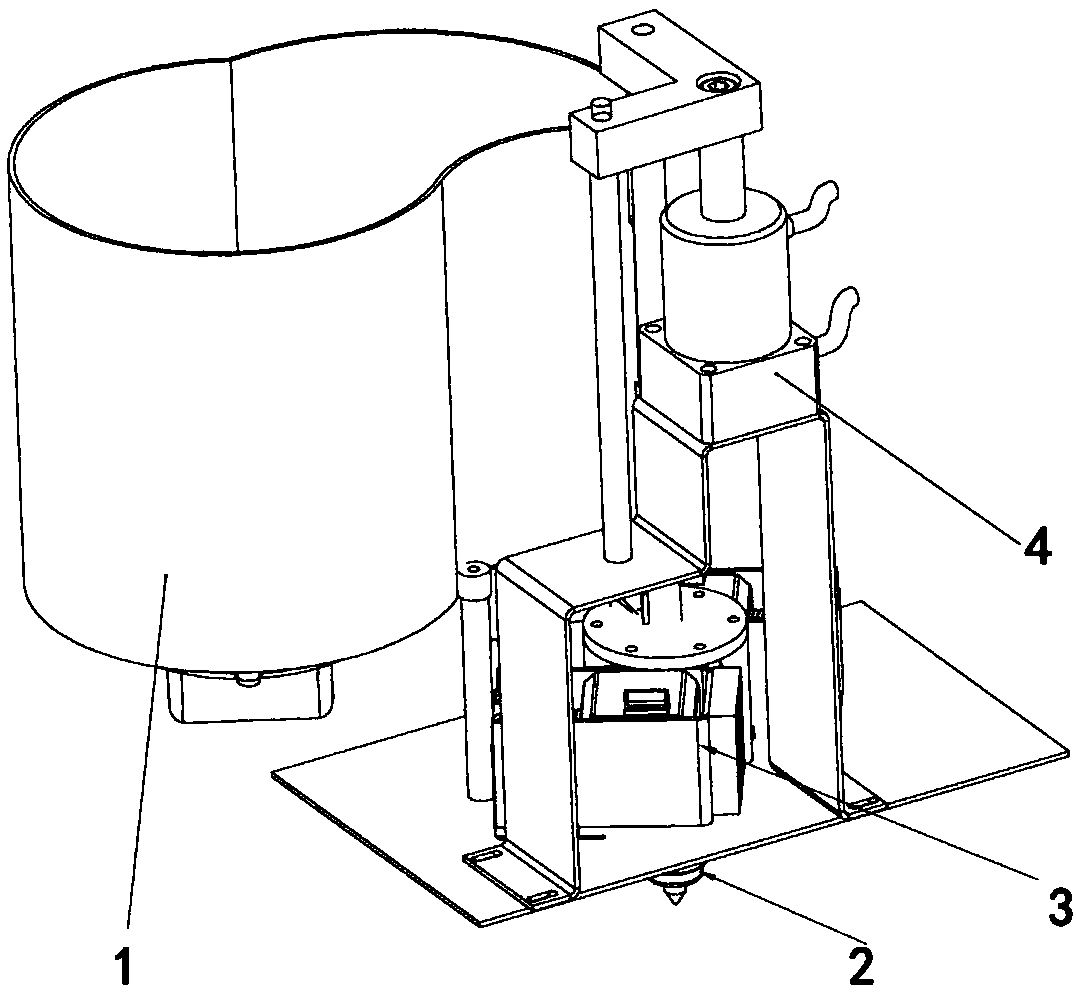

[0020] Such as figure 1 As shown in the three-dimensional structural diagram of the metal 3D printer nozzle device, a metal 3D printer nozzle device includes a charging assembly 1, and a printing head assembly 2 is installed on the lower side of the charging assembly 1. The extruder assembly 3, the extruder assembly 3, the cylinder assembly 4, the charging assembly 1, the printing head assembly, the extruder assembly, the cylinder assembly 4, and the wire material rod 13 are connected through each other.

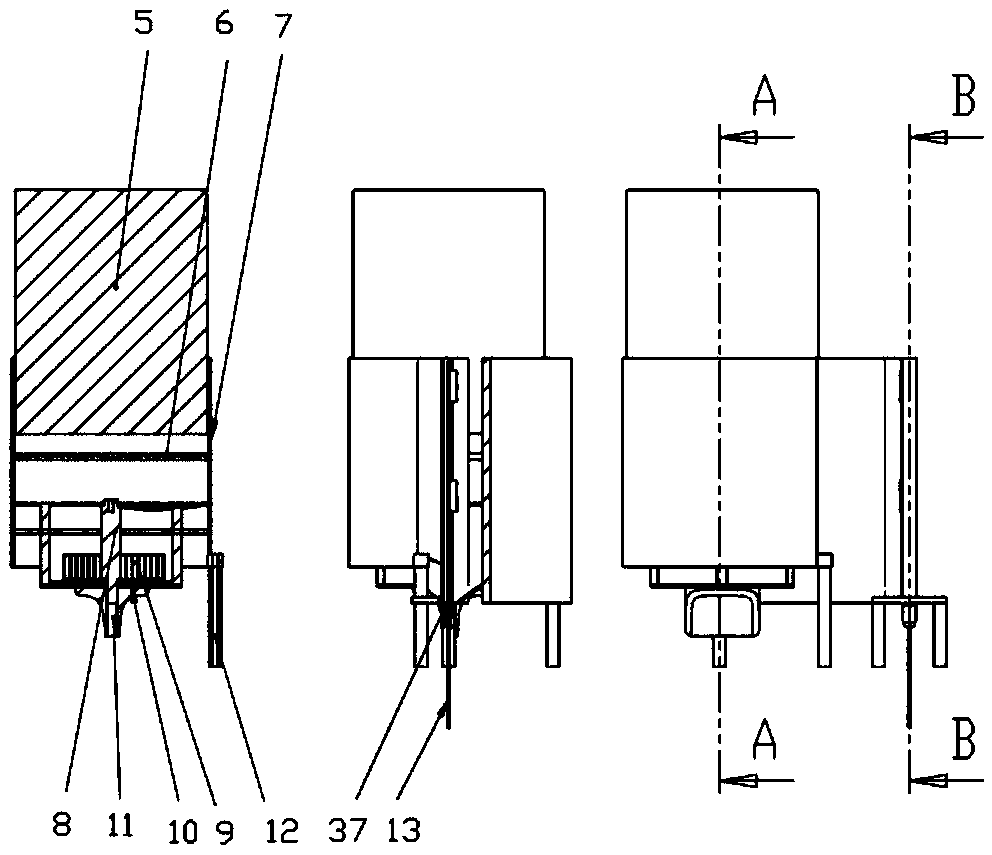

[0021] Such as figure 2 It includes a charging assembly 2, which is equipped with a material barrel 5, a material rod plate 6 is arranged under the material barrel 5, and the outer side of the material bar plate 6 is set as a feeding cylinder 7, and the lower part of the material bar plate 6 is connected with a coil spring shaft 8 , the coil spring shaft 8 is connected to the outer ring with a coil spring 9, the coil spring disc end cover 10 is connected with the feeding c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap