Method for processing bolt hole for framework gearbox mounting seat

A gear box and mounting seat technology, used in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problem that the length of the tool cannot reach the stroke from the first seat plate to the second seat plate, The length of the tool is too long to carry out processing and other problems, so as to achieve the effect of low cost, strong practicability and strong guarantee of the processing method and drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

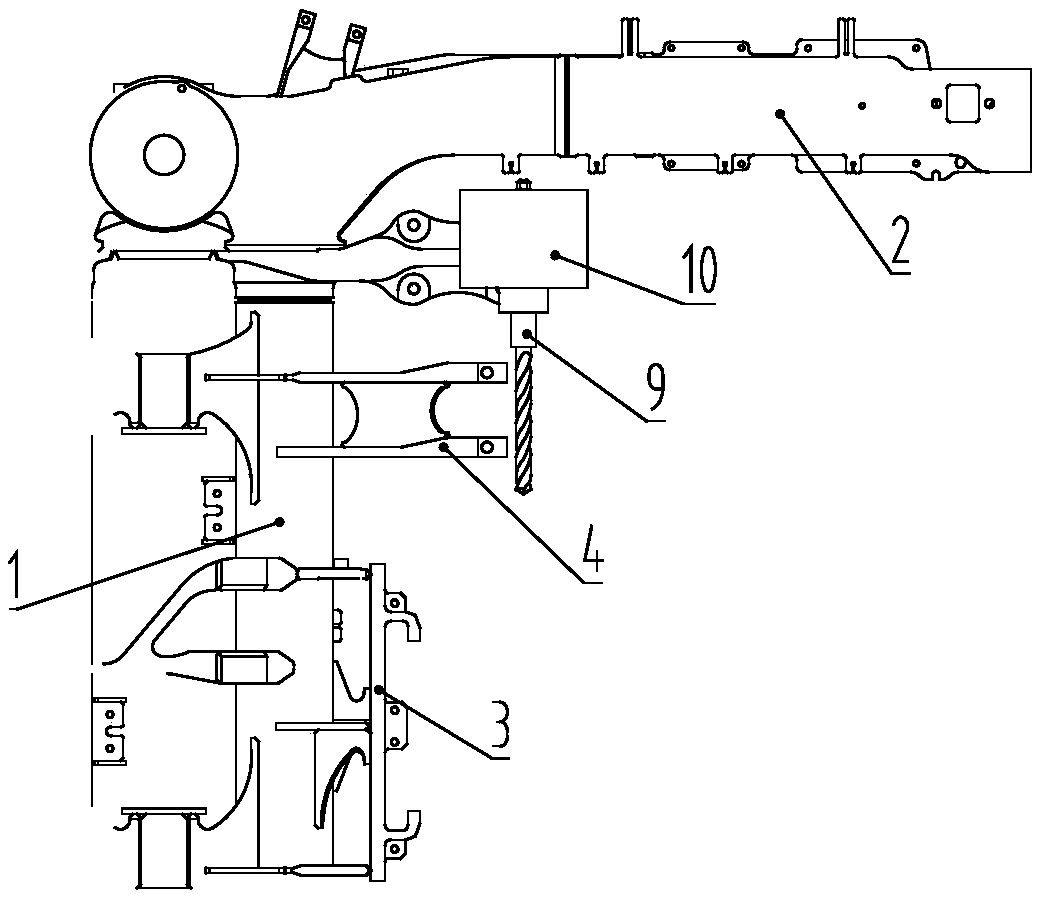

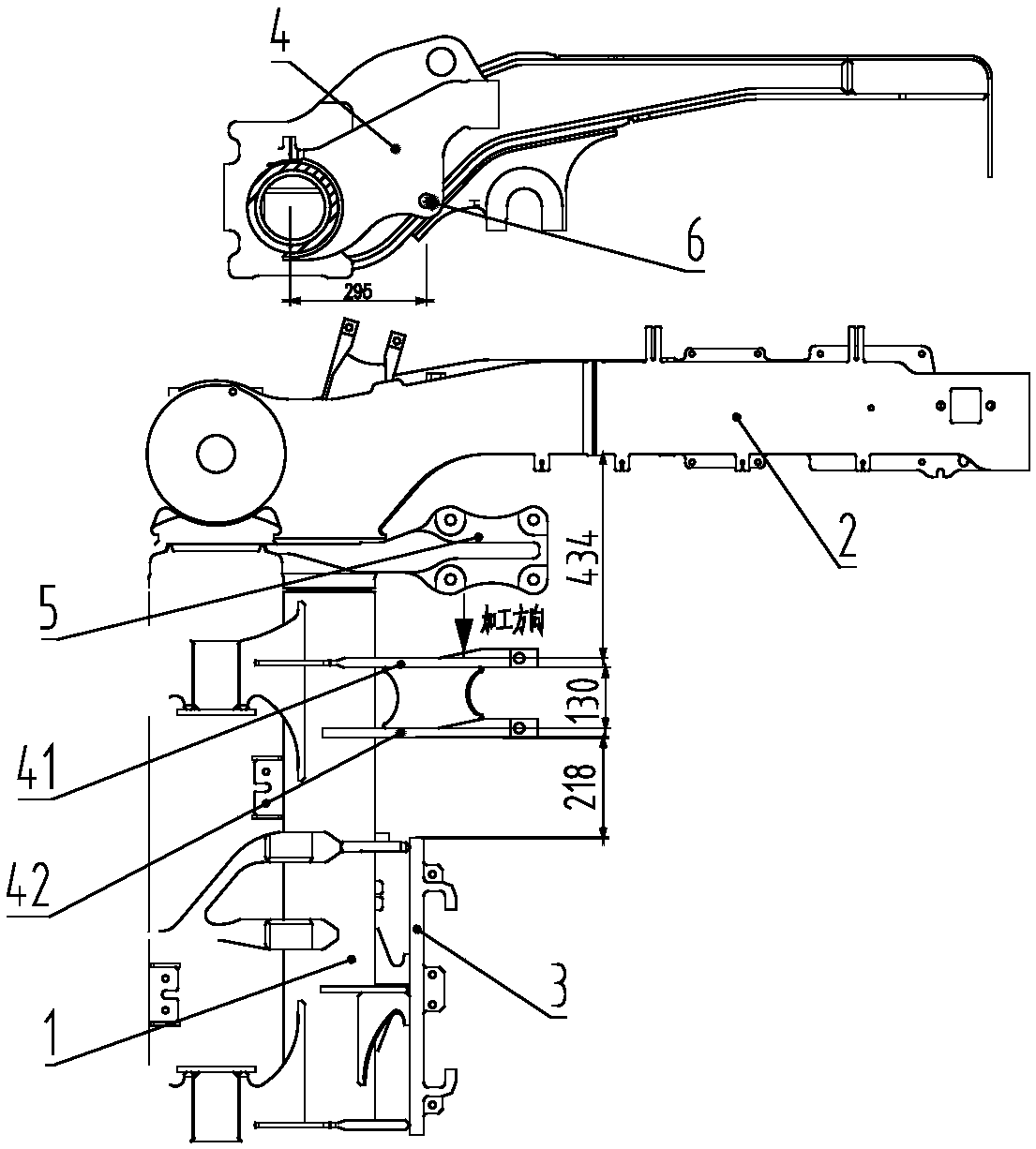

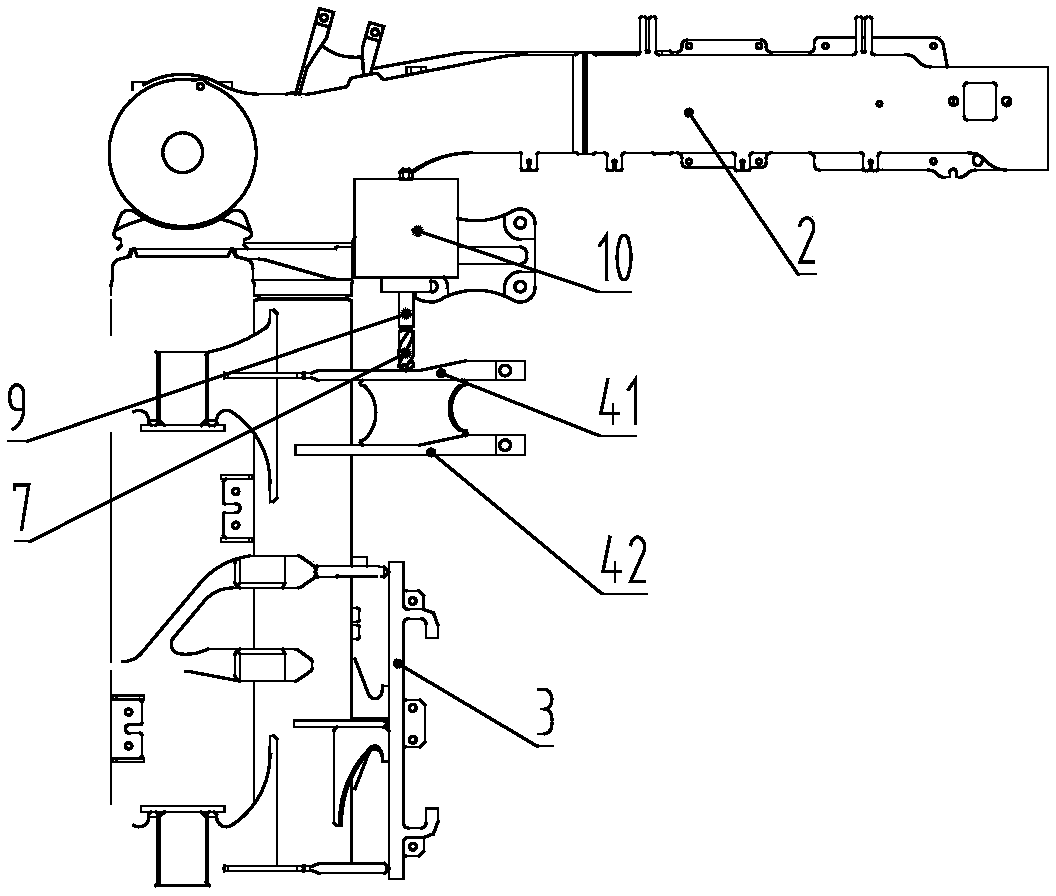

[0032] see Figure 2-6 , the frame includes a motor suspension seat 3 and a gearbox installation seat 4 arranged on the frame beam 1, the motor suspension seat 3 and the frame side beam 2 are respectively located on both sides of the gearbox installation seat 4, and the gearbox The mounting seat 4 includes a first seat plate 41 and a second seat plate 42 parallel to the longitudinal direction of the frame (X direction), the thickness of the first seat plate 41 and the second seat plate 42 are both 20mm, and the The distance is 130mm, the Y direction distance between the second seat plate 42 and the motor suspension seat 3 is 218mm, the distance between the first seat plate 41 and the frame side beam 2 in the transverse direction (Y direction) is 434mm, and the vertical direction of the brake mounting seat 5 ( The Z direction) distance is 218.3mm, and the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com