Metal pipeline notch burr grinding device for machining

A metal pipe and machining technology, applied in grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of difficult incision, easy to damage itself, low efficiency, etc., and achieve high grinding efficiency and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

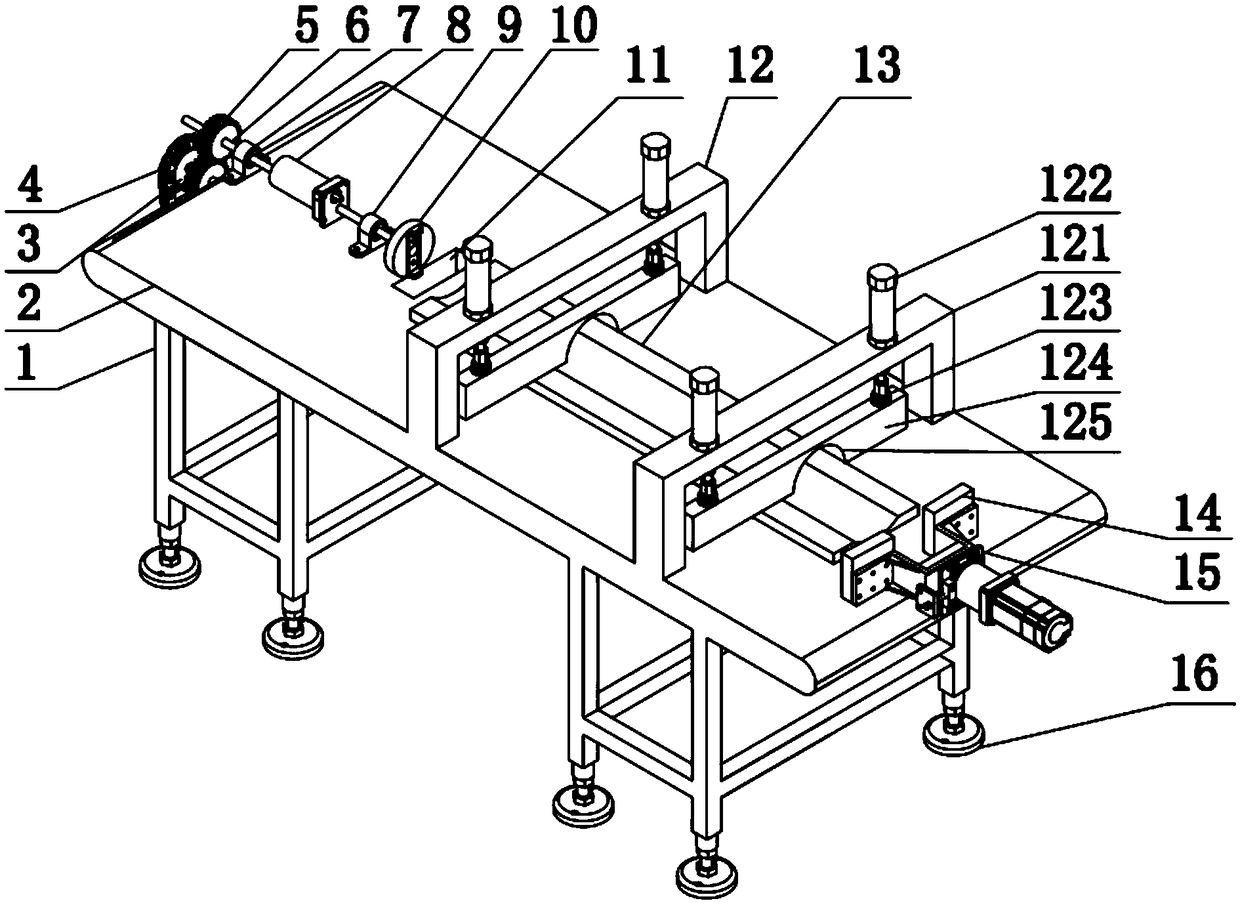

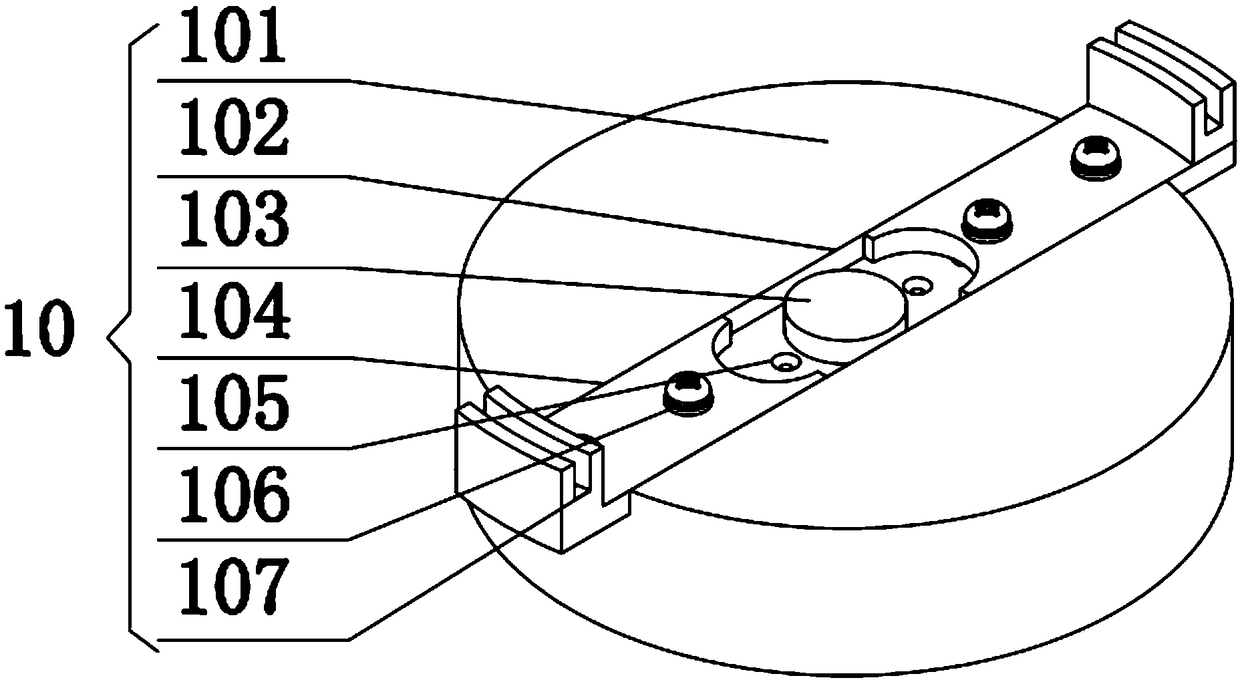

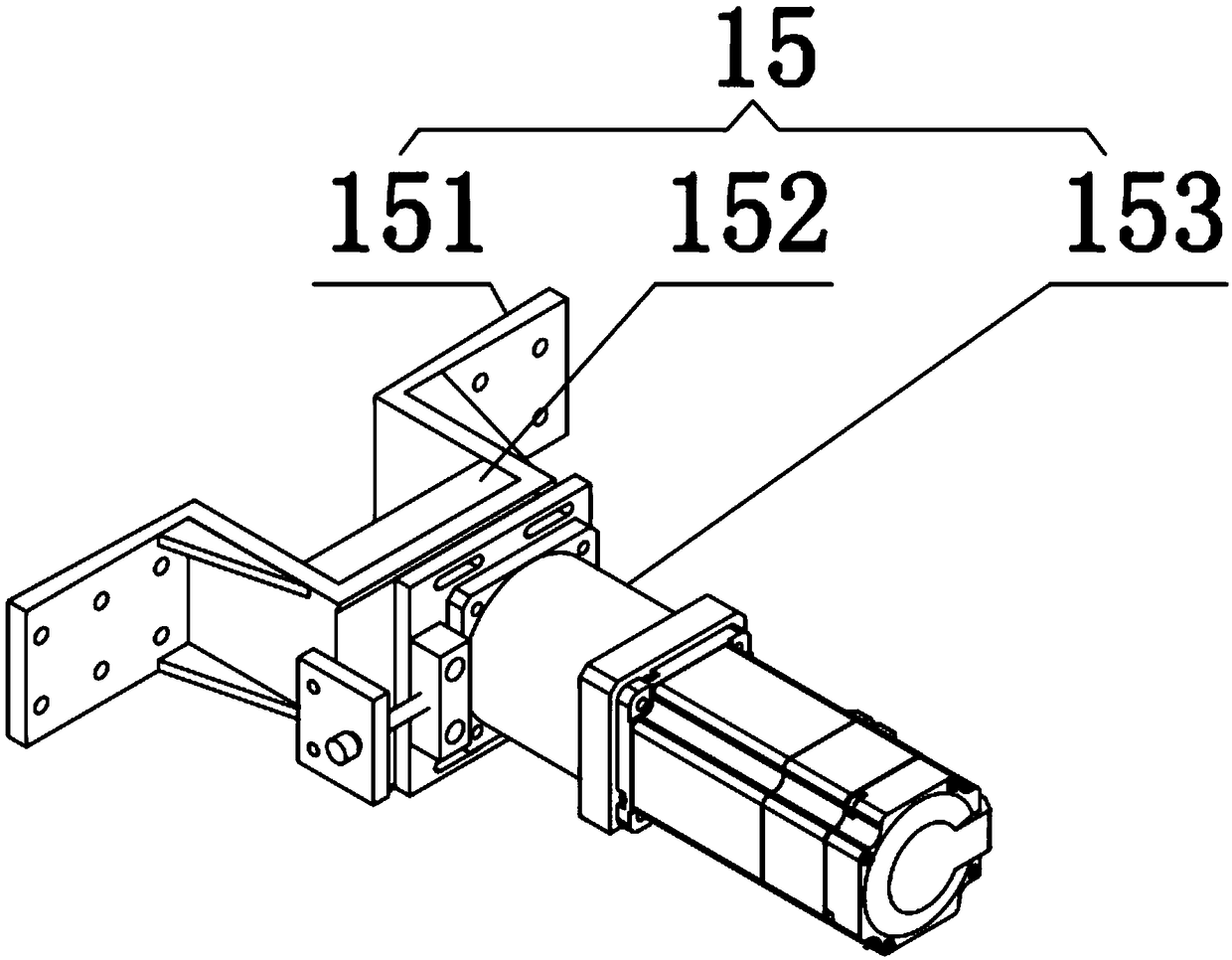

[0021] The present invention provides such Figure 1-4 The shown a metal pipe incision burr grinding device for mechanical processing includes a workbench 2, two groups of racks 1 are fixed and fixed at the bottom of the workbench 2, and a servo motor is welded at one end of the bottom of the workbench 2 17. The output shaft of one end of the servo motor 17 is connected to the input end of the chain gear transmission mechanism 3, the top of the chain gear transmission mechanism 3 is connected to the input end of the rotating shaft 6, and one end of the top of the workbench 2 is fixed A bearing seat 7 is installed, and the other end of the rotating shaft 6 penetrates through the inner bearing inner ring of the bearing seat 7 and is connected to the input shaft of the reducer 8 through transmission, and the output end of the reducer 8 passes through the rotating shaft 6 The inside of the rotating shaft support seat 9 is fixedly connected to the input end of the grinding disc 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com