TFT glass edge grinding device and method

A technology of grinding device and grinding method, which is applied in the direction of grinding driving device, grinding/polishing safety device, grinding machine, etc., which can solve the impact of product quality stability and product consistency, reduce the comprehensive yield of finished products, and affect the production line Production efficiency and other issues, to achieve the effect of increasing the grinding feed speed and product grade, increasing the grinding feed speed, improving the utilization rate and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

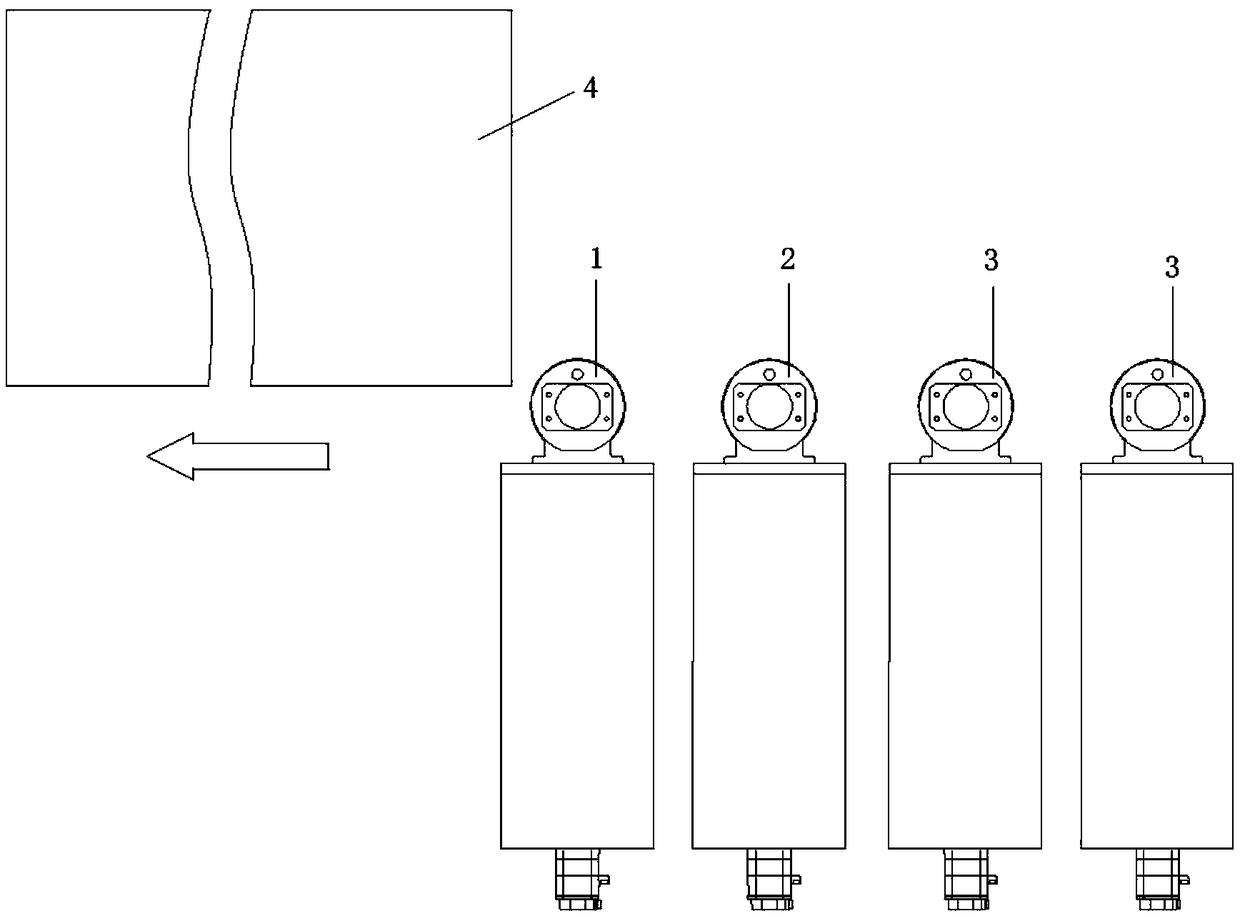

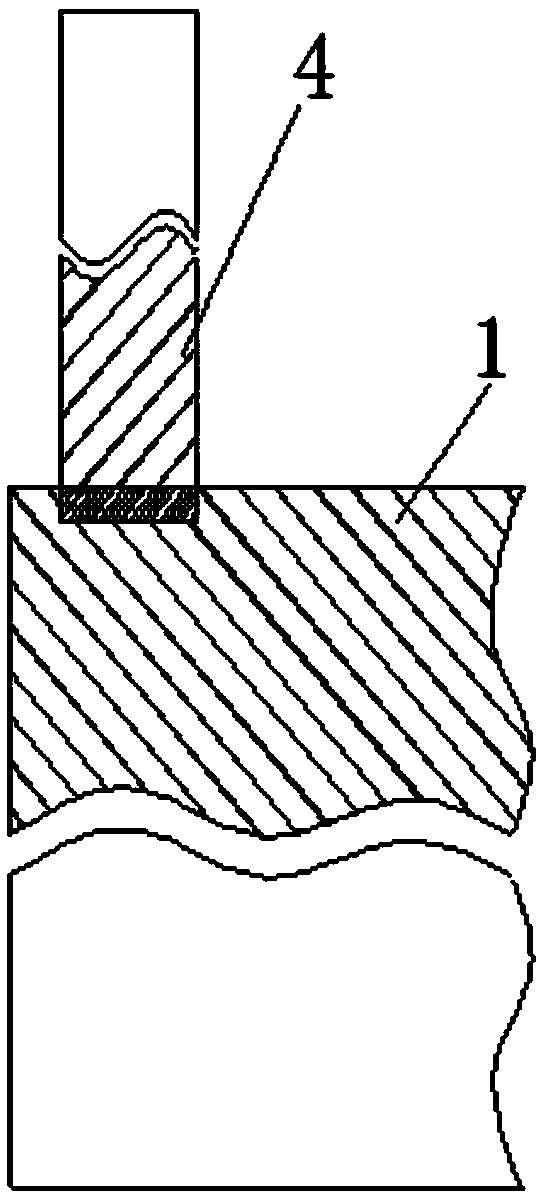

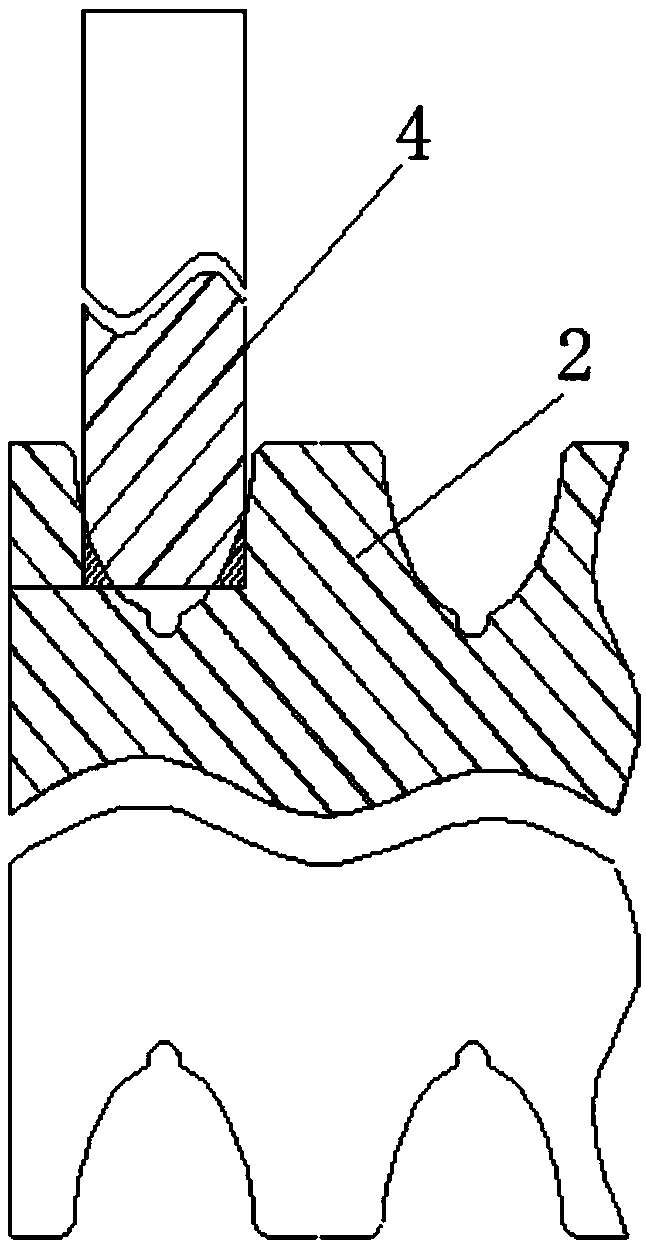

[0030] like figure 1 , figure 2 and image 3 As shown, according to the sequence of processing, a plane grinding wheel 1, a spherical grinding wheel 2 and two polishing wheels are arranged side by side along the grinding direction. The plane grinding wheel 1 is located at the front of the grinding direction. Polishing and grinding, two polishing wheels can achieve secondary polishing, further reducing the surface roughness of the glass, the distance between the bottom surface of the spherical grinding wheel 2 and the surface of the glass 4 after being ground by the flat grinding wheel 1 is greater than 0, reducing the single time of each grinding wheel Grinding amount, increase the overall grinding feed rate.

[0031] like Figure 4 and Figure 5 As shown, assume that the grinding surface size of the plane grinding wheel 1 is D, the grinding surface size of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap