Chemical-mechanical planarization equipment

A chemical-mechanical and flattening technology, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of complex transmission mechanism structure and low wafer transmission efficiency, and achieve flexible equipment layout and high efficiency. The effect of increasing and reducing the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

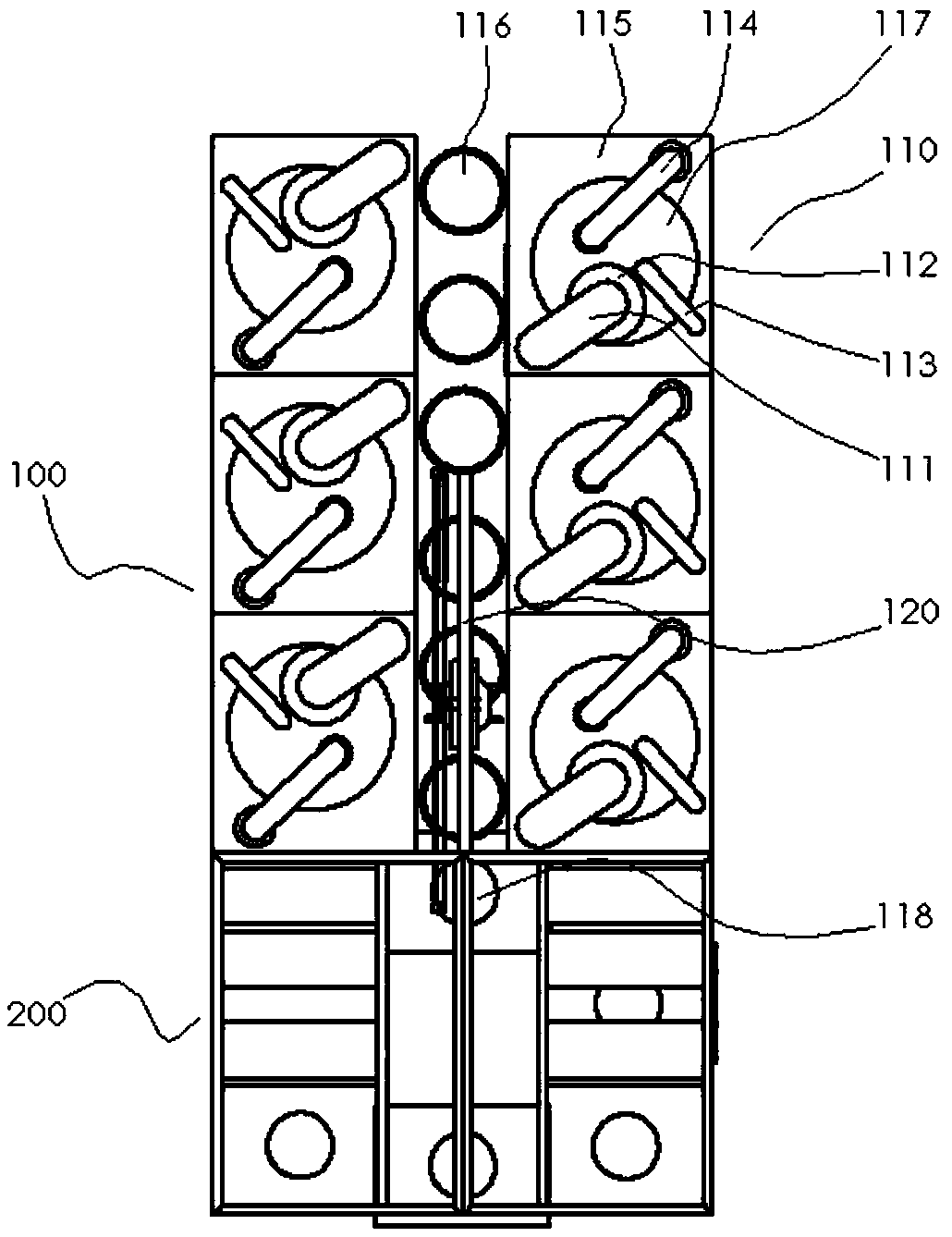

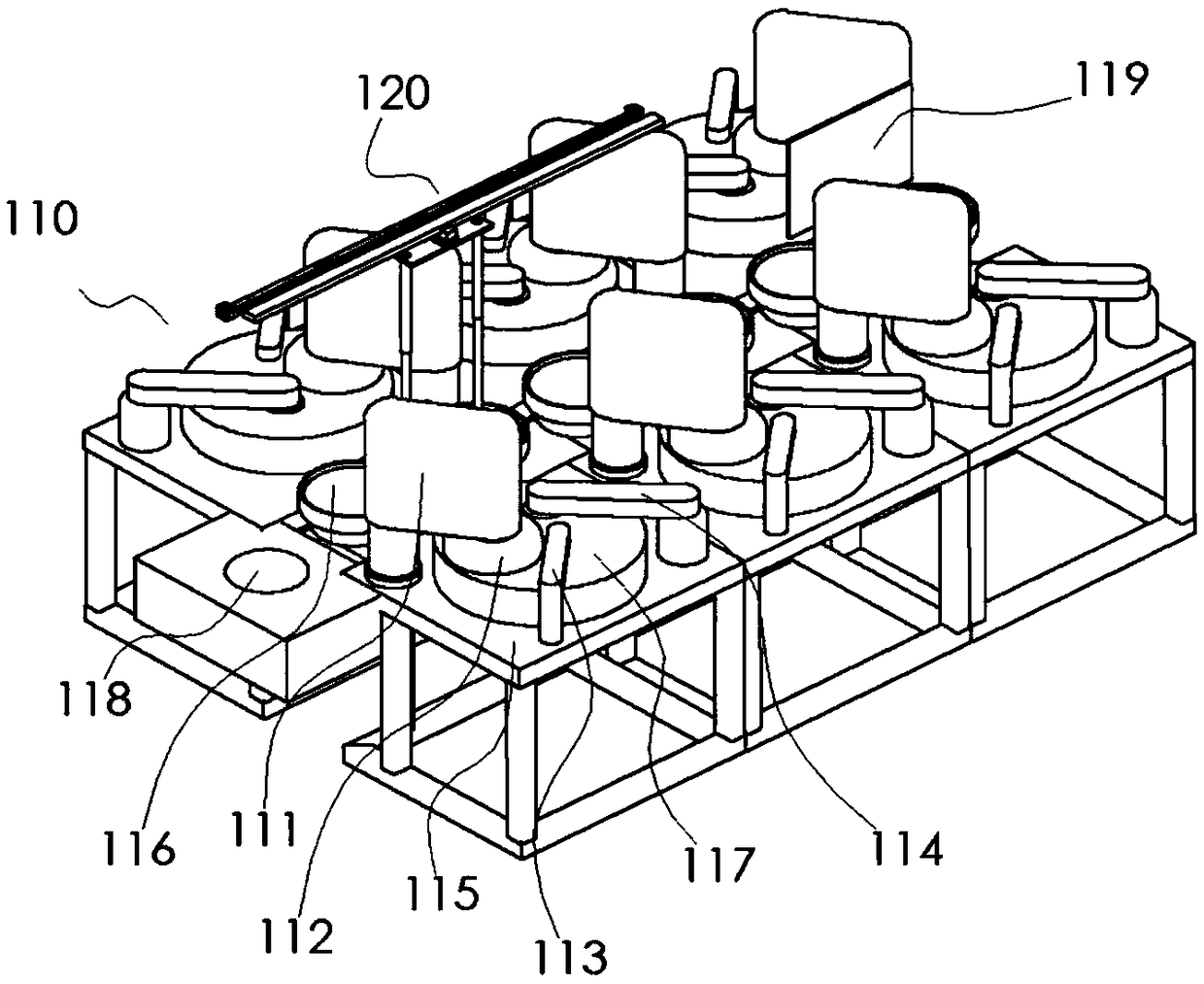

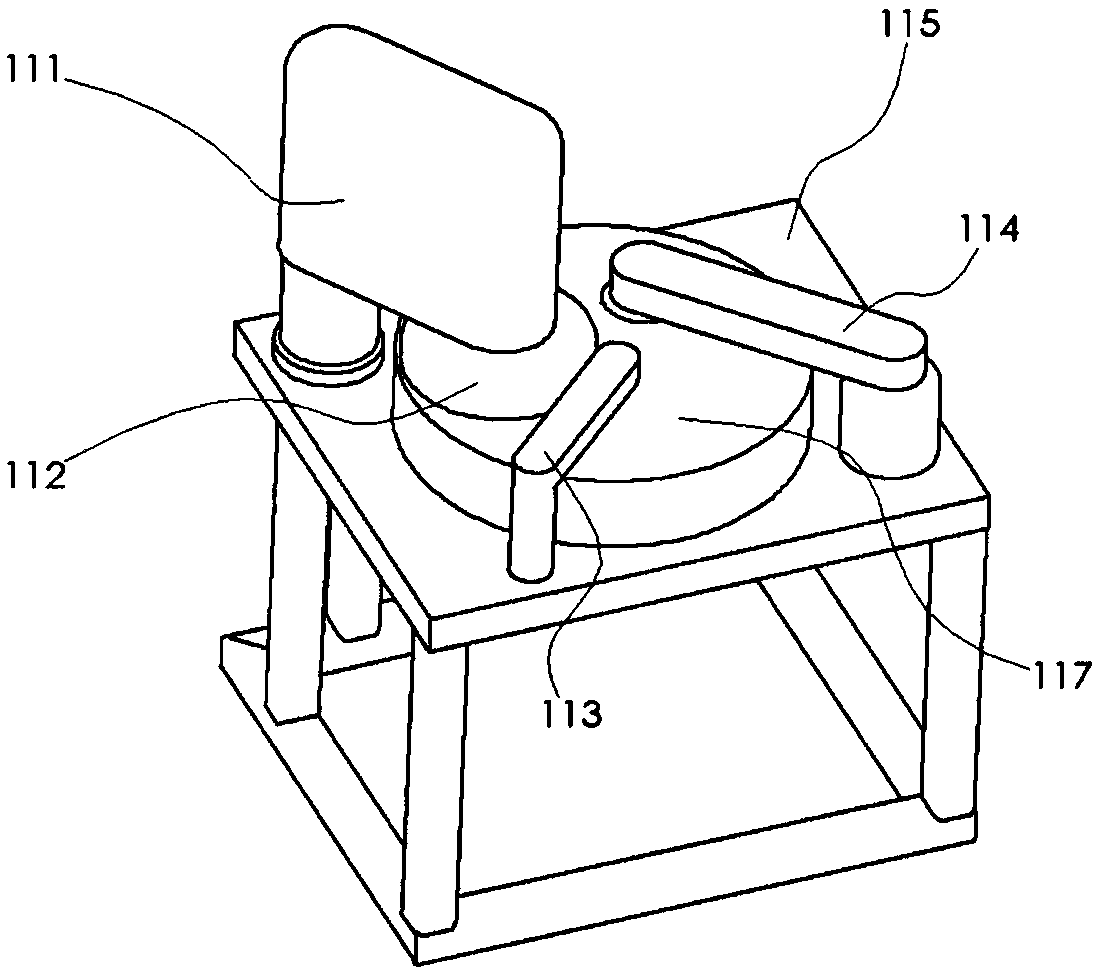

[0037] The chemical mechanical planarization device according to the present invention includes a plurality of polishing units and a plurality of cleaning units. The polishing unit includes a workbench, a polishing disc, a polishing head, a polishing arm, a dresser, a polishing liquid arm, a loading and unloading table, and the like. The polishing disk, polishing head, polishing arm, dresser, and polishing liquid arm are arranged on the workbench according to the processing position. The polishing arm can carry the polishing head to move between the polishing disk and the loading and unloading table. The trimmer dresses the polishing disc with a certain pressure on the polishing disc. The polishing liquid arm can provide chemical liquid required for polishing. When it is necessary to load or unload wafers, the polishing door of the polishing unit is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com