Multi-functional flexible material sorting machine

A material selector and multi-functional technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of long debugging time, high labor cost, and difficult management, and achieve fast and convenient material replacement. High degree of automation, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with accompanying drawing and embodiment:

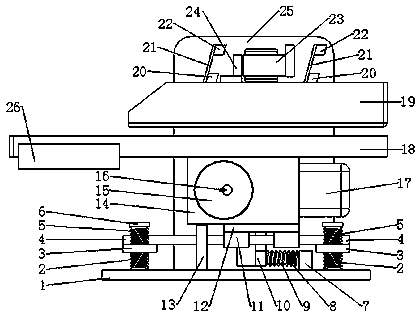

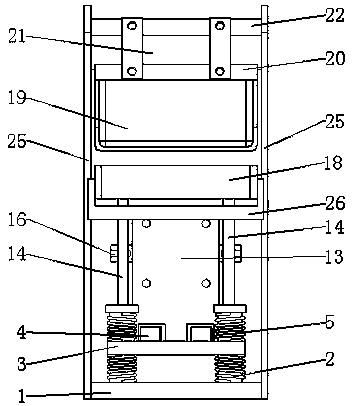

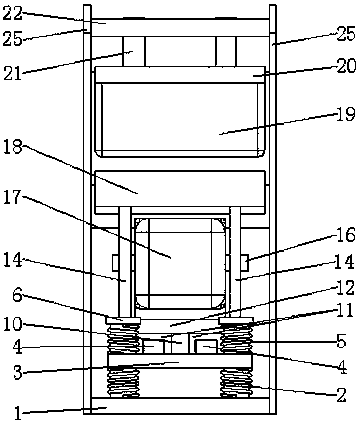

[0026] Such as Figure 1-3 Shown, a kind of multifunctional flexible material selection machine comprises main frame, storage bin 19 and feeder.

[0027] The main engine includes a base plate 1, a motor 17 and a material selection platform 18, and the base plate 1 is fixed with a number of spring fixing columns 6 (in this embodiment, 4 spring fixing columns 6 are respectively arranged on the four corners of the base plate 1). 6 is covered with spring group. Preferably, the spring set includes a first spring 2 and a second spring 5, the lower end of the first spring 2 is fixedly connected to the bottom plate 1, a movable block 3 is arranged between the first spring 2 and the second spring 5, and the movable block 3 is sleeved on the On the spring fixing post 6. Through the action of the first spring 2 and the second spring 5 on the up and down directions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com