Inert gas-protected curved glass forming device

A curved glass and forming device technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of large consumption of inert gas, low structural sealing performance, poor oxygen removal function, etc., and achieve the goal of inert gas Low consumption, long service life, low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

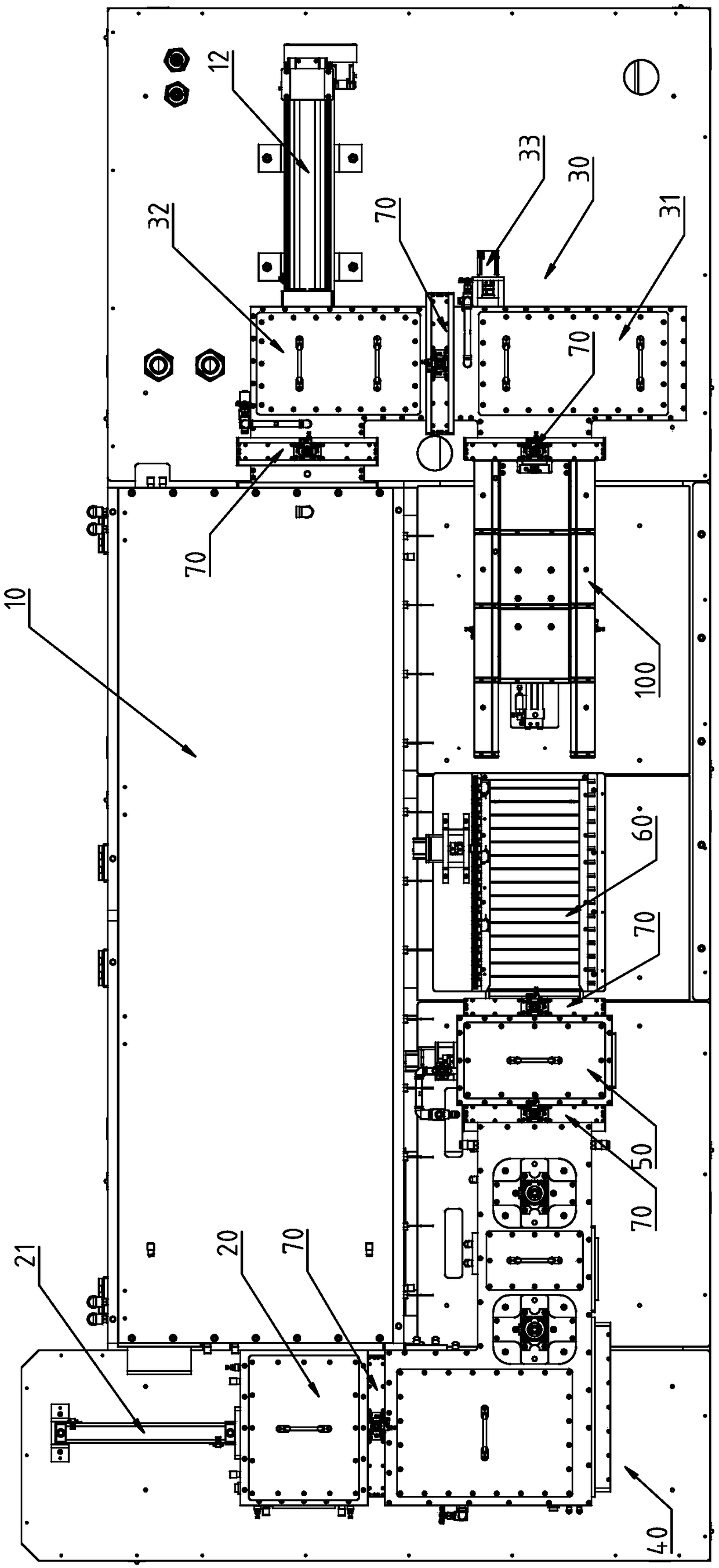

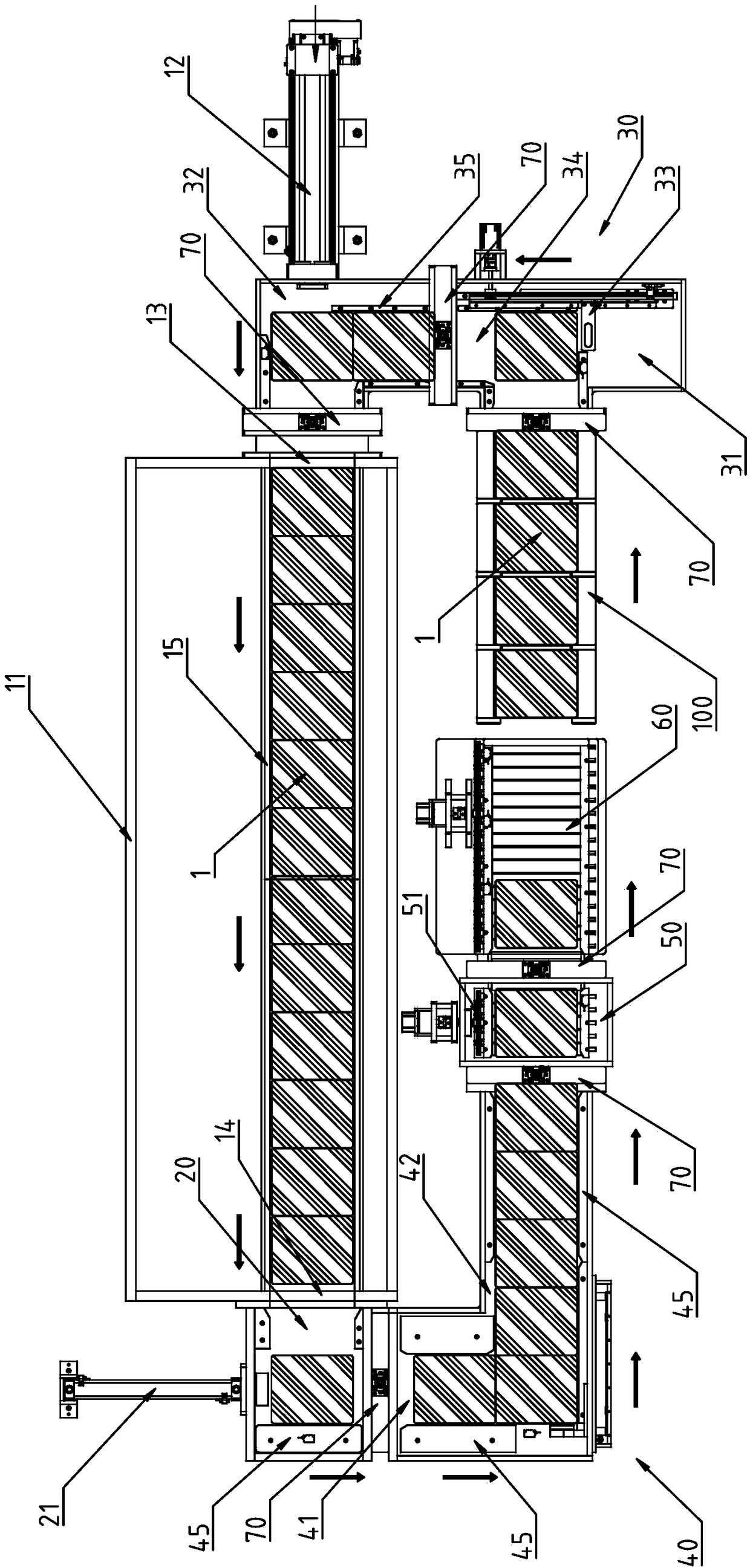

[0035] The structure of the curved glass forming device protected by inert gas of the present invention is as follows Figure 1 to Figure 17 As shown, it includes a tunnel heating furnace 10 , a quench chamber 20 , a closed mold entry channel 30 , a closed mold cooling channel 40 , a discharge chamber 50 , a discharge conveyor belt 60 and a feed mechanism 100 .

[0036] Such as figure 1 and figure 2As shown, the tunnel heating furnace 10 includes a furnace body 11 and a main propulsion mechanism 12, the furnace body 11 includes an inlet 13 and an outlet 14, the furnace body 11 includes a mold channel 15, and the furnace body 11 is filled with an inert gas, The mold channel 15 connects the inlet 13 and the outlet 14 of the furnace body 11 .

[0037] The mold entry passage 30 is connected to the entrance 13 of the furnace body 11 , and the joint of the mold entry passage 30 and the entrance 13 of the furnace body 11 and the entrance of the mold entry passage 30 are respective...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap