Large-size thermal field rapid temperature stabilizing process for pulling of crystals

A process method and large-scale technology, applied in the field of rapid temperature stabilization of Czochralski single crystal large-scale thermal fields, can solve the problems of relatively high skill requirements for crystal pulling operations, lack of crystal pulling operations, and long time for temperature stabilization, and achieve energy saving and stable temperature. The effect of warm working hours, reducing the loss of primary seed crystal, and increasing the production capacity of single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

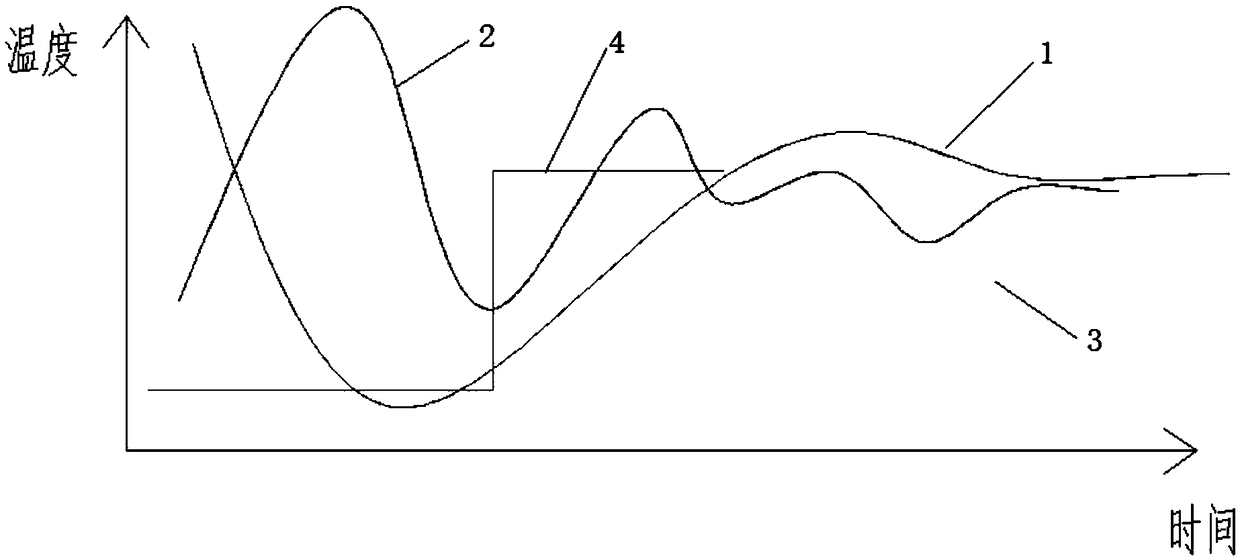

[0024] In the following, an embodiment of the present invention will be used to specifically illustrate the process method for the rapid temperature stabilization of the large-scale thermal field of the Czochralski single crystal. Set the supercooling temperature, and carry out the rapid cooling of the temperature stabilization step in the Czochralski single crystal process, making the temperature reduction faster and more direct, and fine-tuning the temperature through closed-loop control, saving the working hours of temperature stabilization, and increasing the temperature of the temperature stabilization step The automation of adjustment reduces labor intensity and labor costs, improves the consistency of the temperature before single crystal seeding in each furnace, increases single crystal production capacity, reduces the loss of primary se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com