Overflowing channel for water conservancy and hydropower engineering and construction method thereof

An overflow channel, water conservancy and hydropower technology, which is applied in the construction field of the overflow channel and the construction of the overflow channel, can solve the problems such as the inability to meet the long-term safe operation of the project, the difficulty in guaranteeing the construction quality, and the complicated construction process. , to achieve the effect of improving easy construction performance, improving efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

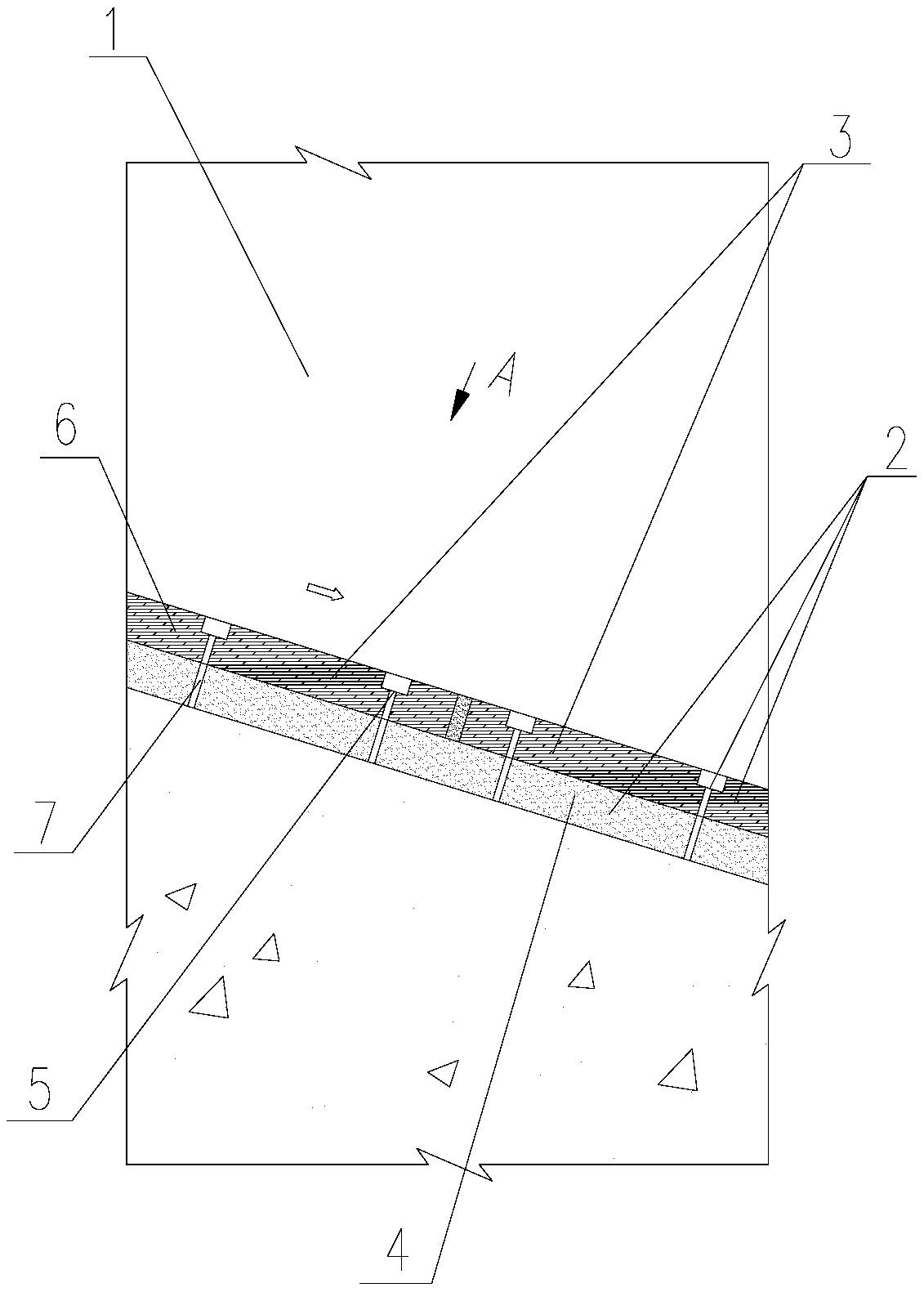

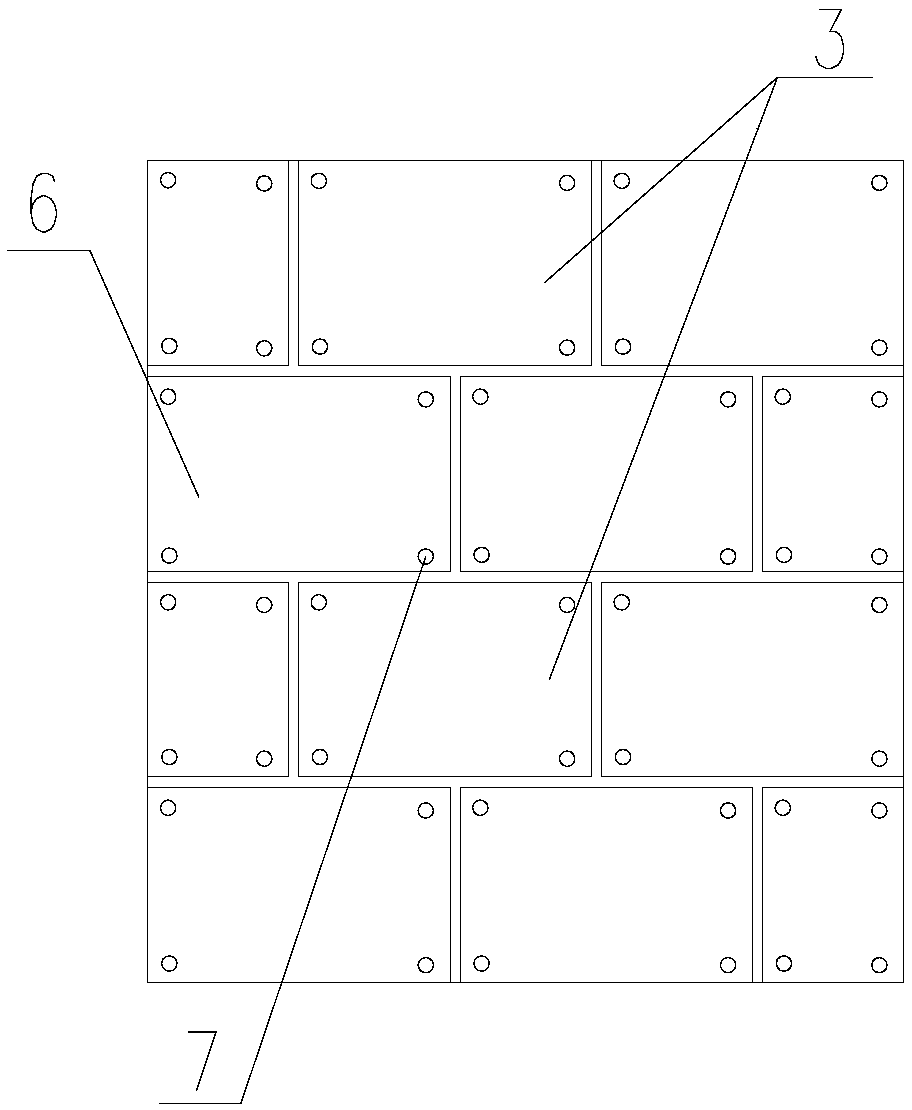

Embodiment 1

[0030] The specific steps are,

[0031]1) First, according to the engineering conditions and the need for anti-abrasion protection, select an industrial microcrystalline panel with an appropriate thickness, generally 2cm to 3cm, and cut the microcrystalline panel into rectangular microcrystalline plates of the same size. Generally, the size of the short side is not less than 80cm.

[0032] 2) Perform secondary processing on the cut microcrystalline platelets in the processing workshop. The specific processing requirements are as follows: 2 to 5 bolt anchoring holes are processed on each microcrystalline plate, and the surface size of the hole is required to match the nut, and the bottom layer size of the hole is matched to the screw. After the bolt is fixed to the microcrystalline plate, the top surface of the nut and the microcrystalline plate are on the same plane, the screw and the nut are closely combined with the microcrystalline plate, and the gaps are scraped in and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com