Plugging method of pressure-bearing water piping in deep foundation pit engineering

A technology for deep foundation pits and water pipes, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of accelerating the influence range of pressurized water piping, expanding the channel of pressurized water piping, and being unable to solidify, so as to eliminate the safety of foundation pits. The effect of eliminating hidden dangers, ensuring project quality, and eliminating hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

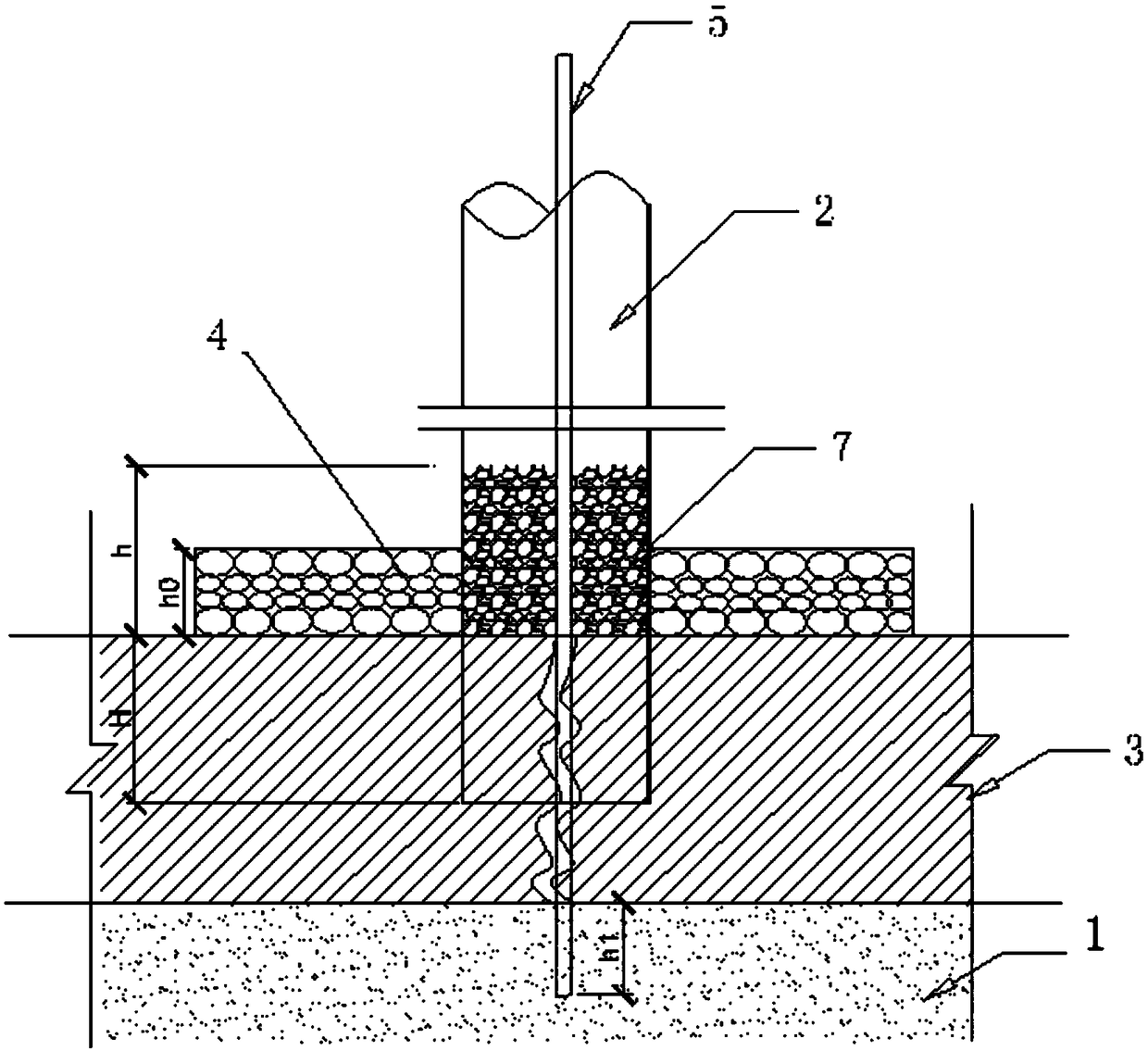

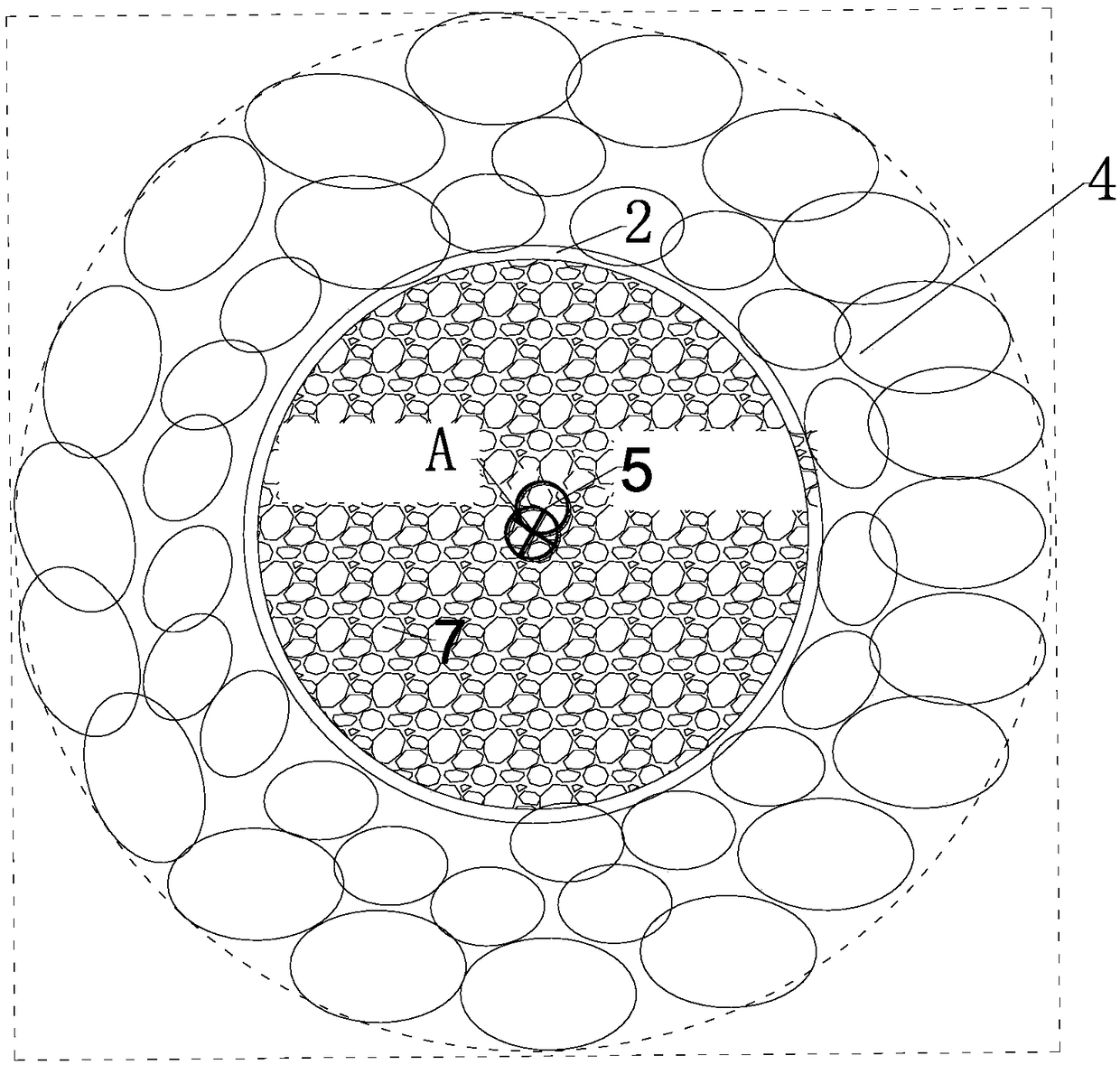

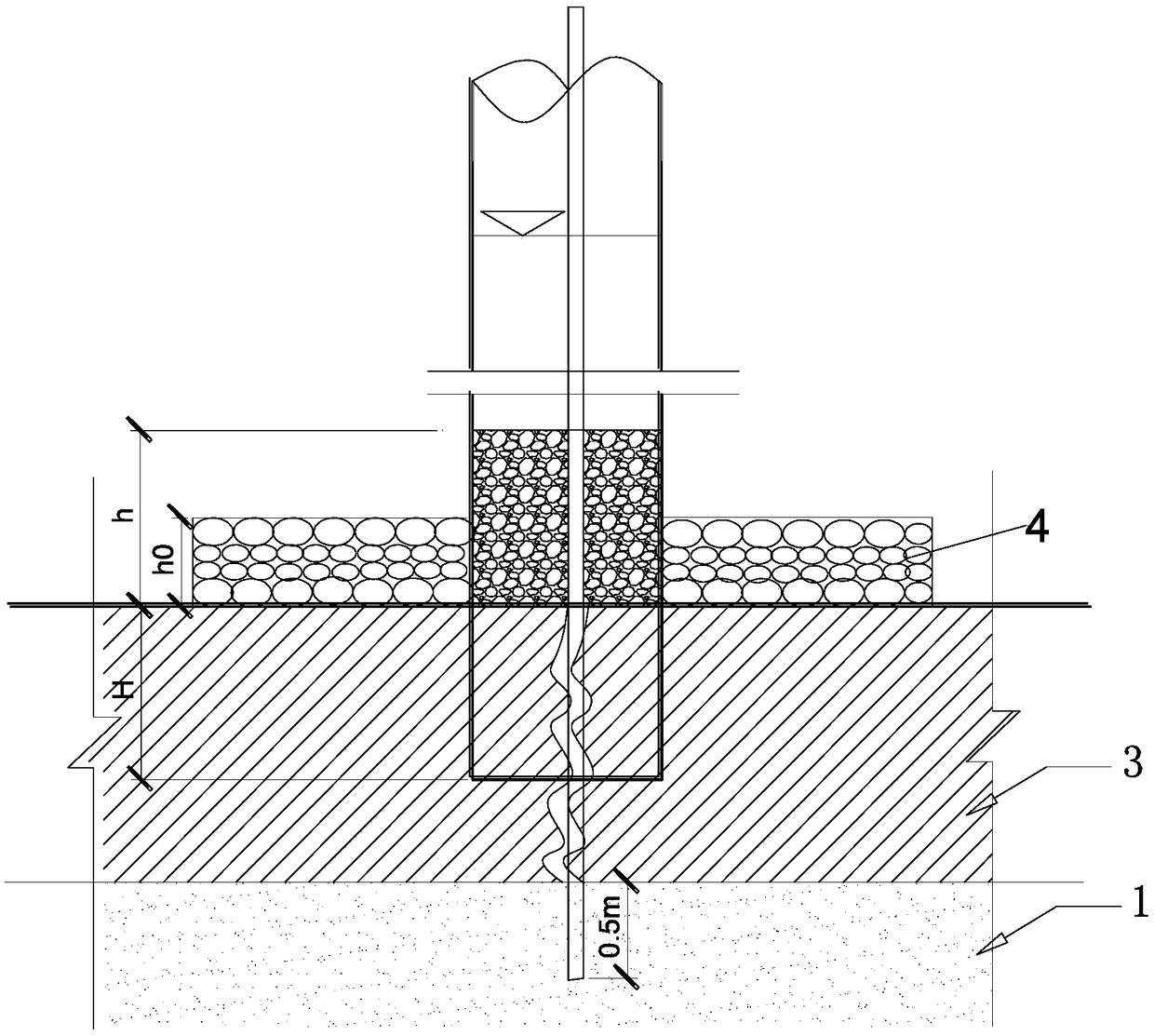

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and examples of implementation

[0022] A method for plugging pressurized water piping in deep foundation pit engineering provided by this embodiment includes the following steps:

[0023] The first step, as attached figure 1 And attached figure 2 As shown, with the confining water piping point A as the center, the prepared steel pipe 2 is inserted into the cohesive soil layer 3 below the excavation surface, and the depth of the steel pipe 2 pressed into the cohesive soil layer 3 is H, H≥2m, the The inner diameter of the steel pipe 2 should be larger than the water gushing area of the pressurized water pipe, and the diameter should not be less than 273mm, and the wall thickness should not be less than 5mm.

[0024] The second step, as attached figure 1 And attached figure 2 As shown, the bagged cement or bagged sand 4 is filled within t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com