A Method of Utilizing the Goaf as a Mine General Return Air Shaft

A technology for gobs and return air shafts, applied in mining equipment, mining equipment, mine/tunnel ventilation, etc., can solve problems such as increased prevalence of occupational diseases, increased burden on main fans, and lengthened return air routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

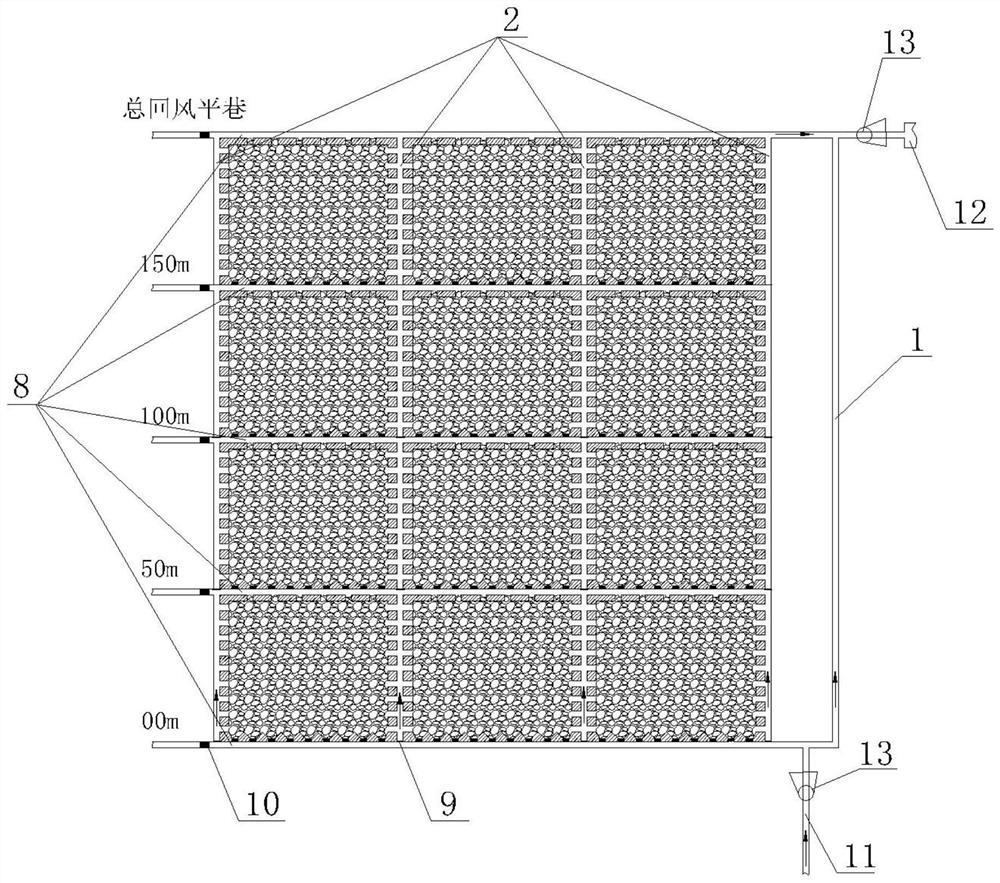

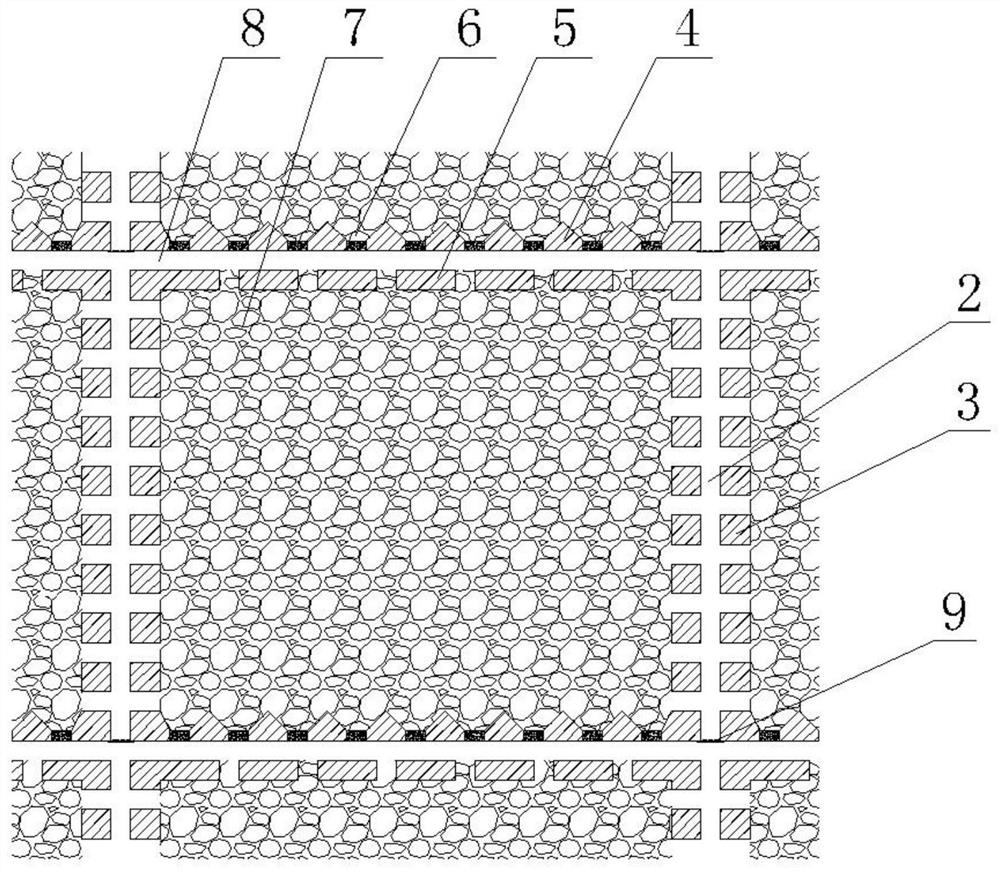

[0025] The method of using the goaf as the total air return shaft of the mine disclosed by the present invention is aimed at metal mines mined underground with steeply inclined extremely thin ore bodies, thin ore bodies or medium-thick ore bodies. In the field of mining, the ore body with a thickness of less than 0.8m is called an extremely thin ore body, the ore body with a thickness of 0.8-4m is called a thin ore body, and the ore body with a thickness of 4-10 to 15m is called a medium-thick ore body. A metal ore body with an ore body dip greater than 55° is called a gold dip ore body.

[0026] Steeply inclined medium-thick ore bodies and thin ore bodies can usually be mined by shallow hole ore retention method, shallow hole ore retention followed by waste rock filling method and layered cemented filling method. Mining methods such as shallow hole ore retention method, shallow hole ore retention followed by waste rock filling method, and wall cutting and filling method are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com