Anti-outburst method for coal mine single coal seam protective layer pressure relief and permeability-increasing type sequential layer extraction

A technology for protecting layers and coal seams, which is applied in mining equipment, earthwork drilling, gas discharge, etc., to achieve the effects of convenient operation, reduced risk, and elimination of gas outburst accidents in coal mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

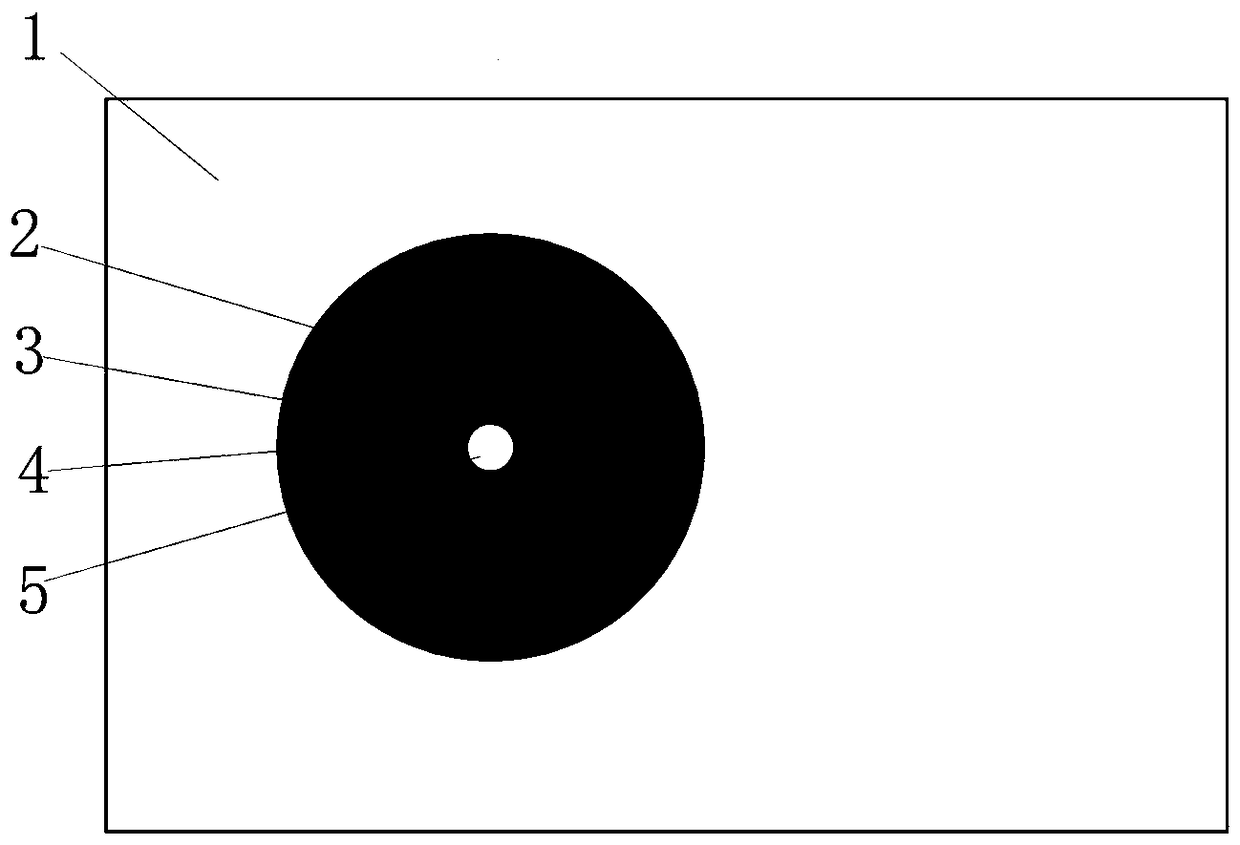

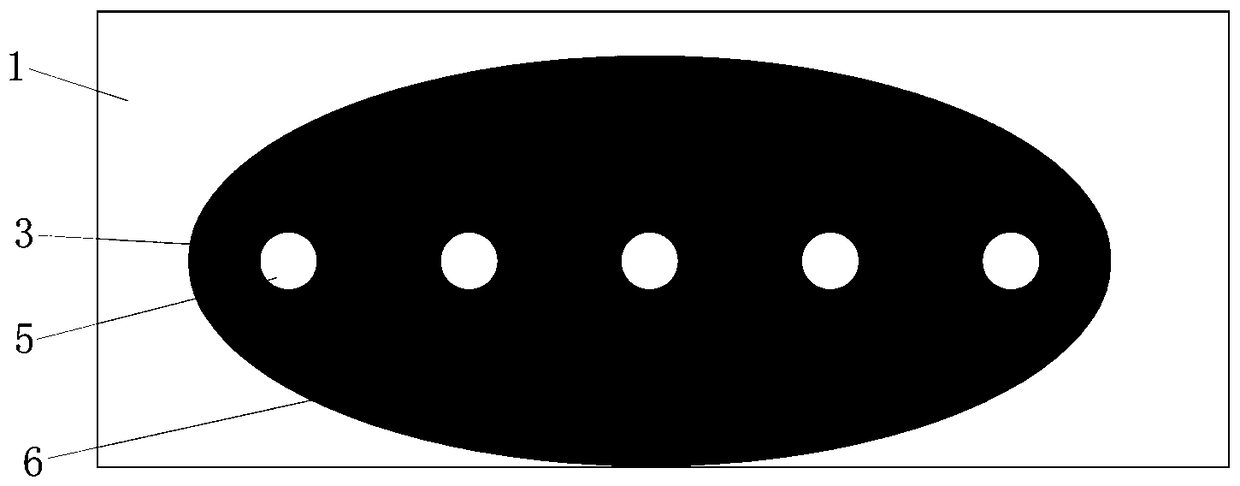

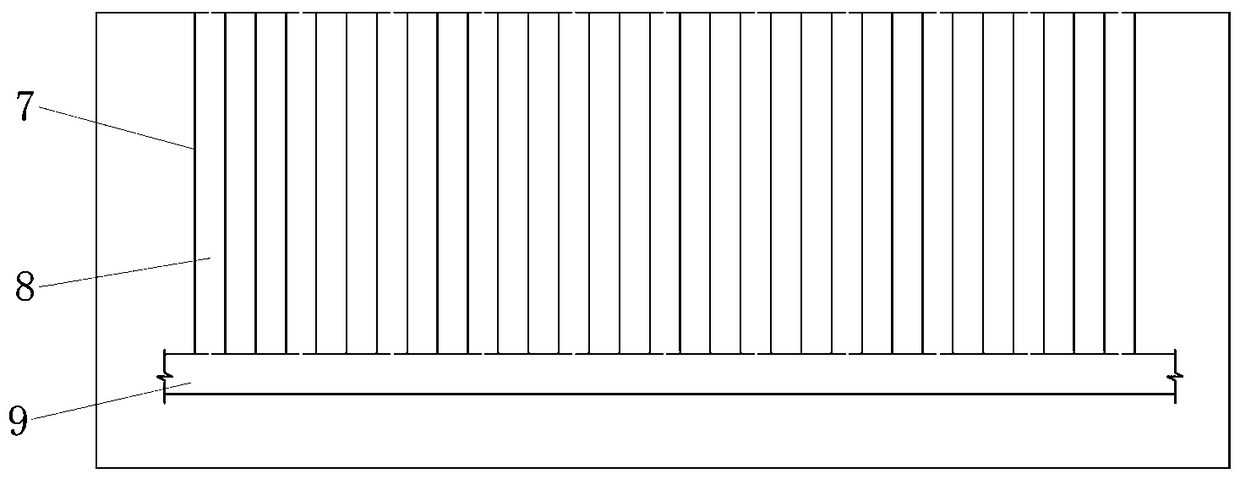

[0017] In the figure, the number 1 represents the coal seam, the number 2 represents the area affected by drainage, the number 3 represents the disturbance area of the coal seam, the number 4 represents the loose area of the coal seam, the number 5 represents the pressure relief borehole, and the number 6 represents the pressure relief area of the shed effect. 7 represents linear intensive pressure relief boreholes, number 8 represents gas drainage boreholes, and number 9 represents roadways.

[0018] In order to make the purpose, technical solution and advantages of the present invention more clear and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

[0019] In view of the lack of effective pressure-relief and anti-reflection assistance in coal mine outburst-prevention drainage technology for coal seam gas pre-extraction, the embodiment provides a single coal seam prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com