High pressure anti-cavitation cut off ball valve with noise reduction function

A cut-off ball valve and anti-cavitation technology, which is applied in the direction of the cock including the cut-off device, the device for absorbing fluid energy of the valve, and the details of the valve, can solve the problems that the ball valve cannot reduce the pressure, control the noise and adjust the poor performance, and achieve reduction Effects of noise control, flow rate reduction, and pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

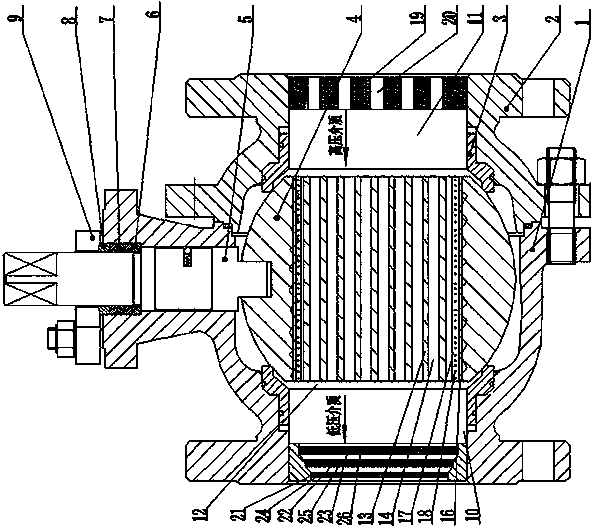

[0032] as attached figure 1 As shown, a noise-reducing high-pressure anti-cavitation cut-off ball valve of the present invention has a structure including a main valve body 1, an auxiliary valve body 2, a valve seat 3, a valve stem 5 and a ball 4, and the auxiliary valve body 2 is installed on the main valve body. On the valve body 1, the valve seat 3 is installed in the valve body composed of the main valve body 1 and the auxiliary valve body 2, the ball 4 is installed in the valve seat 3, and the valve stem 5 is fixedly connected with the ball 4; the valve stem 5 is connected with the main valve body 1 and A packing pad 6 is installed between the auxiliary valve body 2, and a packing gland 8 is installed above the packing pad 6, and a packing 7 is filled between the packing gland 8 and the packing pad 6, and a packing pressure plate 9 is installed on the upper side of the packing gland 8. The material of packing 7 adopts PTFE.

[0033] The main valve body 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com