Method for measuring average grain size of secondary recrystallization of oriented silicon steel finished plate

A technology of average grain size and secondary recrystallization, which is used in measuring devices, testing crystals, and material analysis by optical means. Wide application range and small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

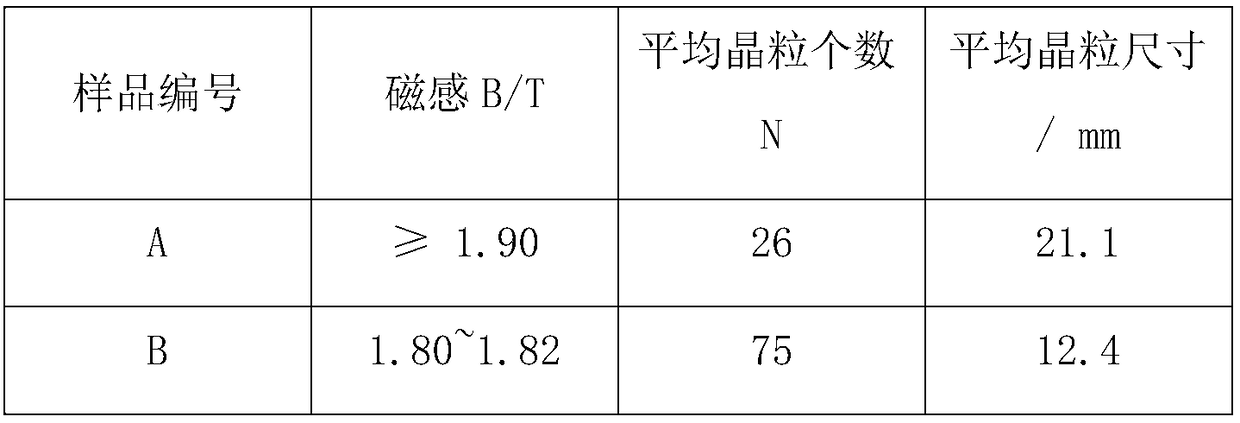

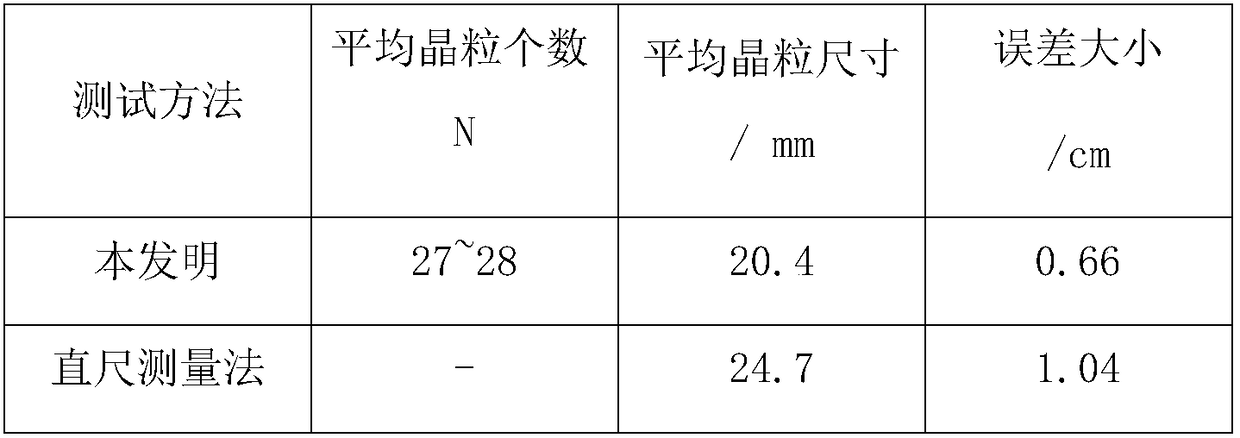

Examples

Embodiment 1

[0033] A method for measuring the average grain size of secondary recrystallization of finished oriented silicon steel plate 1

[0034] Characterize the shape of the grain with a circle, and characterize the average grain size with the diameter of the average grain, and the method may further comprise the steps:

[0035] (1) Randomly cut 15 finished oriented silicon steel plates with a size of 300×30mm (rolling direction×horizontal direction) from different positions in the oriented silicon steel coil;

[0036] (2) Heat 1500ml of 20% hydrochloric acid aqueous solution to 80°C, then add the finished oriented silicon steel plate, and macroscopically corrode for 4 minutes to obtain the secondary recrystallized macrostructure of the finished oriented silicon steel plate.

[0037] (3) Observe the macroscopic structure of erosion with the naked eye, and count the total number of grains of secondary recrystallization of 15 oriented silicon steel finished plates, wherein, the total nu...

Embodiment 2

[0042] A method for measuring the average grain size of the secondary recrystallization of the finished oriented silicon steel plate 2

[0043] Characterize the shape of the grain with a circle, and characterize the average grain size with the diameter of the average grain, and the method may further comprise the steps:

[0044] (1) Randomly cut 17 finished oriented silicon steel plates with a size of 300×30mm (rolling direction×horizontal direction) from different positions in the oriented silicon steel coil;

[0045] (2) Heat 1800ml of 25% hydrochloric acid aqueous solution to 90°C, then add the finished oriented silicon steel plate, and macroscopically corrode for 5 minutes to obtain the secondary recrystallized macrostructure of the finished oriented silicon steel plate.

[0046] (3) Observe the corroded macrostructure with the naked eye, and count the total number of secondary recrystallized grains of 17 oriented silicon steel finished plates, wherein, the total number of...

Embodiment 3

[0051] A method for measuring the average grain size of the secondary recrystallization of the finished oriented silicon steel plate 3

[0052] Characterize the shape of the grain with a circle, and characterize the average grain size with the diameter of the average grain, and the method may further comprise the steps:

[0053] (1) Randomly cut 20 pieces of finished oriented silicon steel plates with a size of 300×30mm (rolling direction×transverse direction) from different positions in the oriented silicon steel coil;

[0054] (2) Heat 2000ml of 30% hydrochloric acid aqueous solution to 100°C, then add the finished oriented silicon steel plate, and macroscopically corrode for 6 minutes to obtain the secondary recrystallized macrostructure of the finished oriented silicon steel plate.

[0055] (3) observe the macroscopic structure of erosion with the naked eye, and count the total number of secondary recrystallized grains of 20 oriented silicon steel finished plates, wherein, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com