Intelligent system for detecting and marking cracks of double-block sleepers

A technology of intelligent detection and crack detection, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problem of inability to rationalize cracks in double-block sleepers, intelligent tracking records and post-tracing, and unidentifiable cracks in double-block sleepers Problems such as inspection, production time, and non-standard inspection conclusions can reduce manual stamping operations, save manual stamping time, and improve quality traceability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

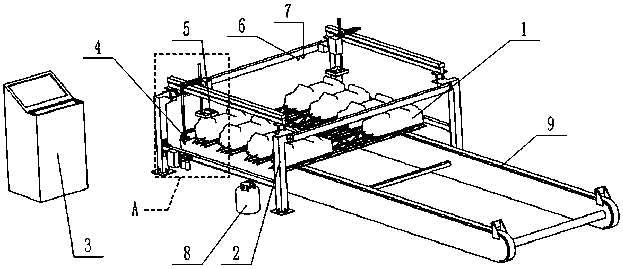

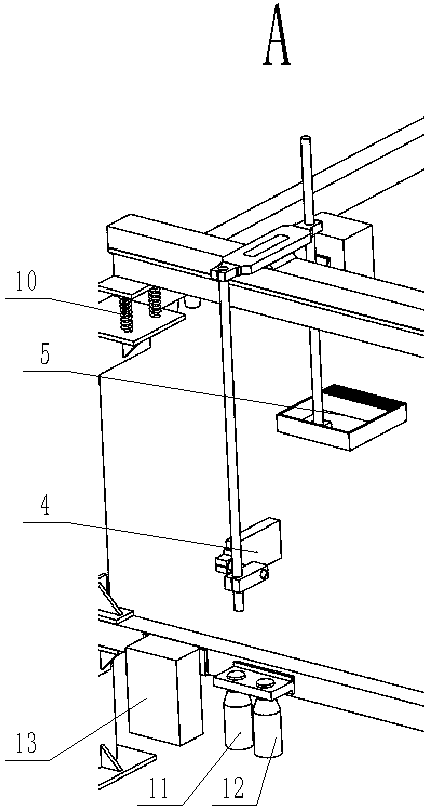

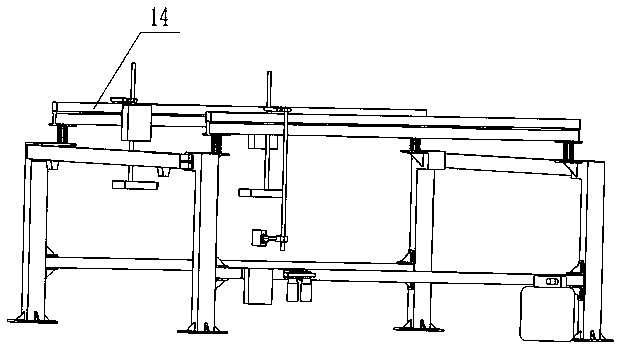

[0027] Such as Figure 1-Figure 3 As shown, an intelligent detection and identification system for double-block sleeper cracks of the present invention includes a crack detection system, a spraying system and a transmission system. The crack detection system includes a high-definition camera 5 and a computer 3. The spraying system includes a printer, a gas spray head 6 and The alcohol atomizing nozzle 7, the transmission system includes a conveyor belt 9 and a sleeper position sensor 16; the high-definition camera 5 and the inkjet printer nozzle 4 are arranged below the X-axis of the two-axis reciprocating machine 14, and the gas nozzle 6 and the alcohol atomizing nozzle 7 are arranged on two sides. Below the Y axis of the shaft reciprocating machine 14; the gas nozzle 6 and the alcohol atomizing nozzle 7 clean the double-block sleeper 1 on the conveyor belt 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com