Engineering machinery assembly line online perception system

A technology for construction machinery and perception systems, applied in transmission systems, bus networks, digital transmission systems, etc., can solve problems such as time-consuming information collection, errors, and labor time occupation of workers, and achieve the effect of rapid response and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

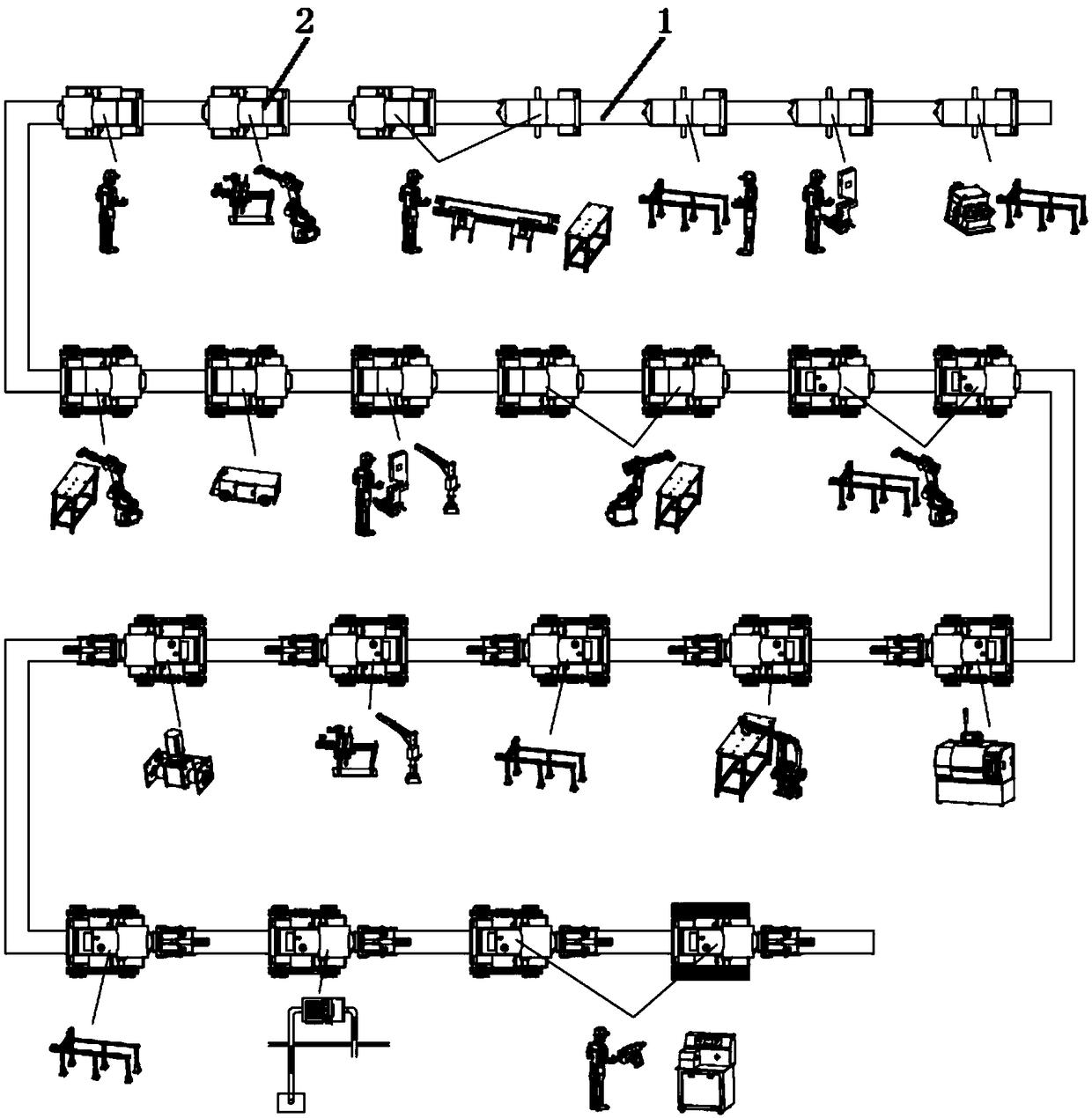

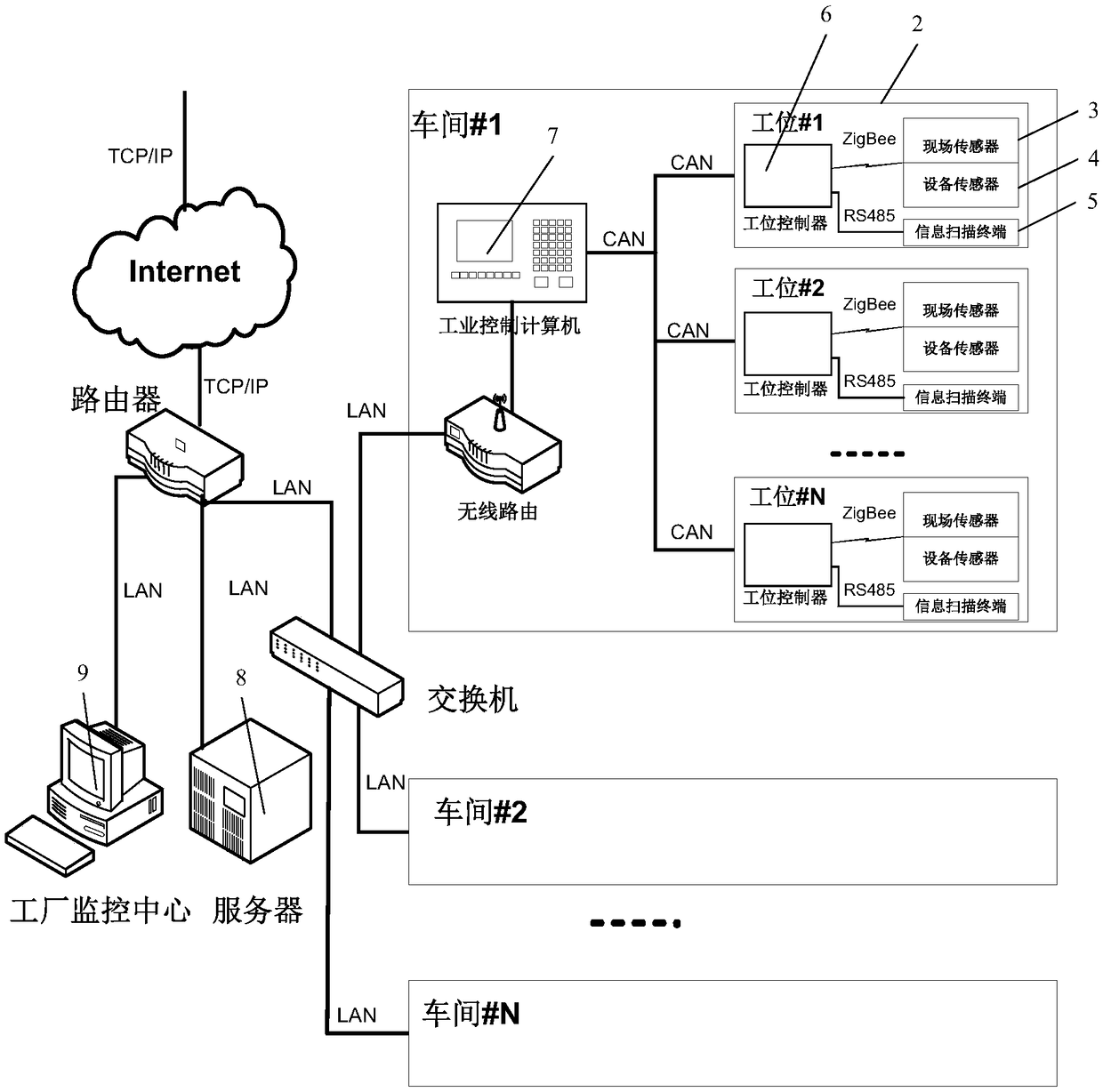

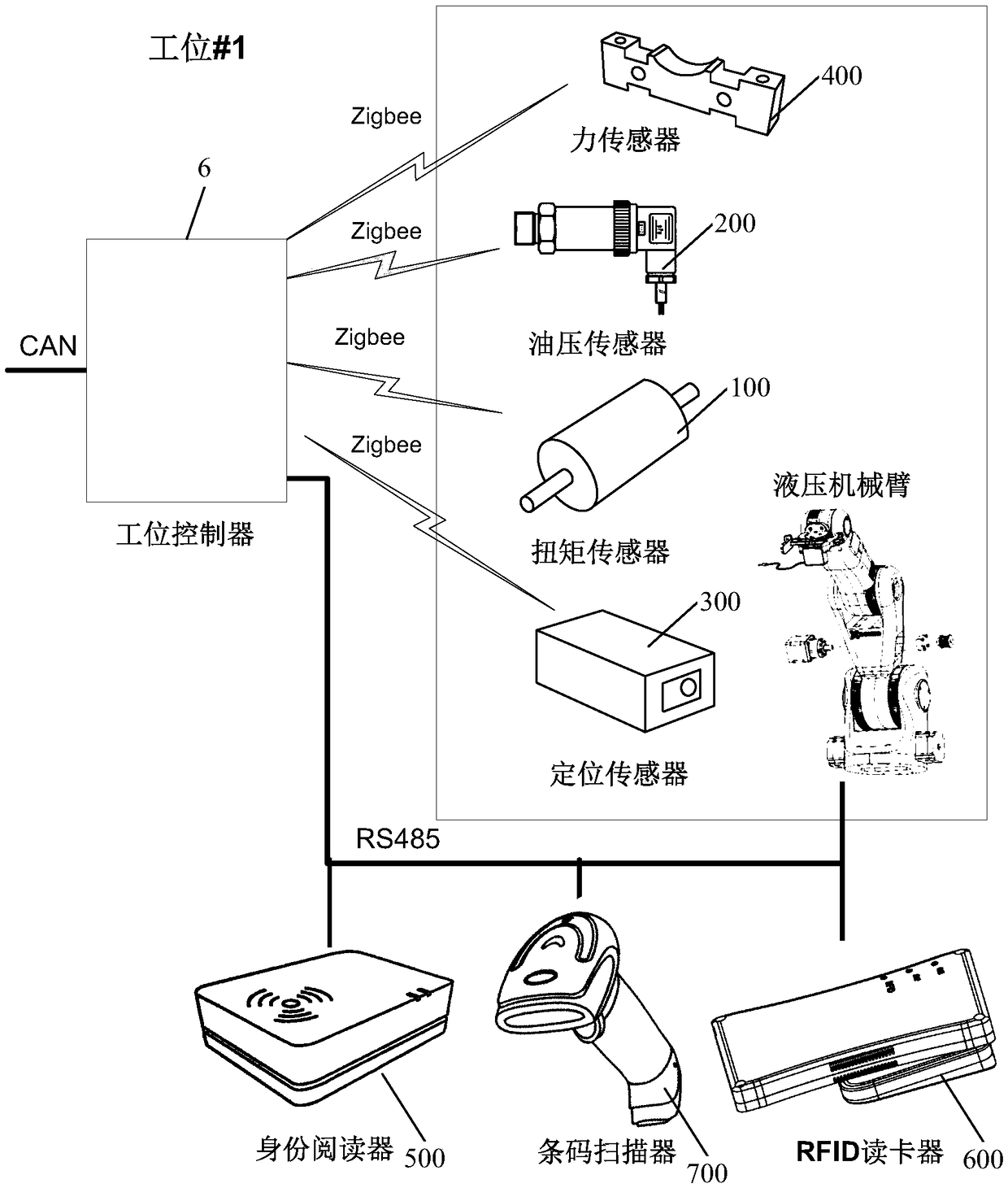

[0031] The present invention provides an online perception system for construction machinery assembly production line, such as Figure 1-2 As shown, an automated production line 1 is included, and the automated production line 1 includes a plurality of assembly stations 2; each assembly station 2 is provided with a field sensor 3, an equipment sensor 4, an information scanning terminal 5 and a station controller 6, and the field sensor 3 and the device sensor 4 are connected to the station controller 6 through ZigBee communication, and the information scanning terminal 5 is connected to the station controller 6 through RS485 communication; all station controllers 6 in the same workshop are connected to an industrial control computer 7 through the CAN bus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com