Coupled inductor structure

A technology of coupled structure and coupled inductance, applied in circuits, electrical components, electric solid devices, etc., can solve the problems such as the self-resonant frequency cannot be too high, the quality factor of the coupled inductance is not ideal, and the frequency of use is limited, so as to improve the utilization of chip area. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

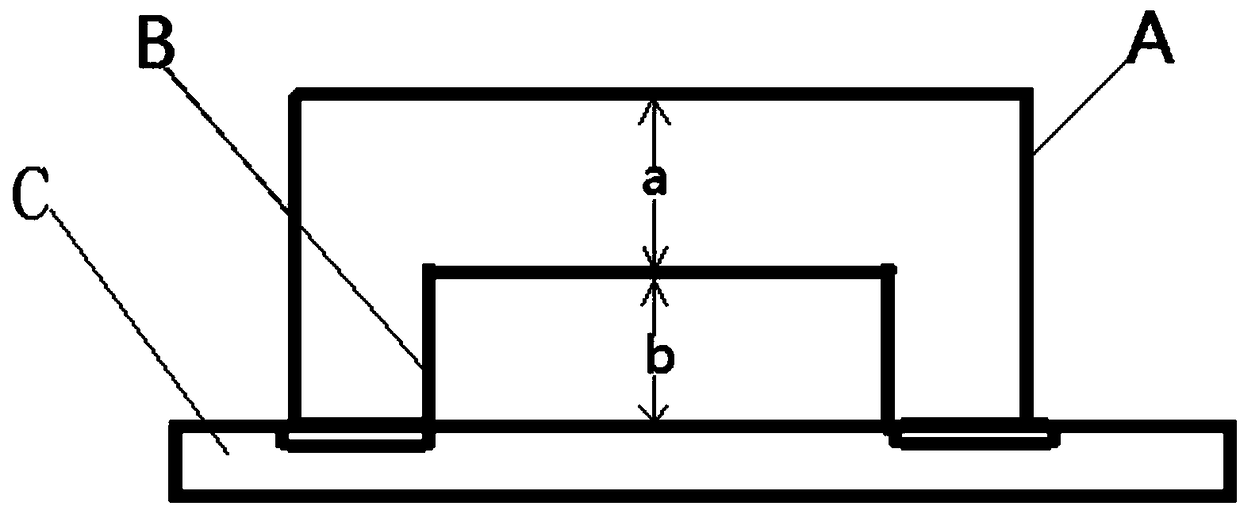

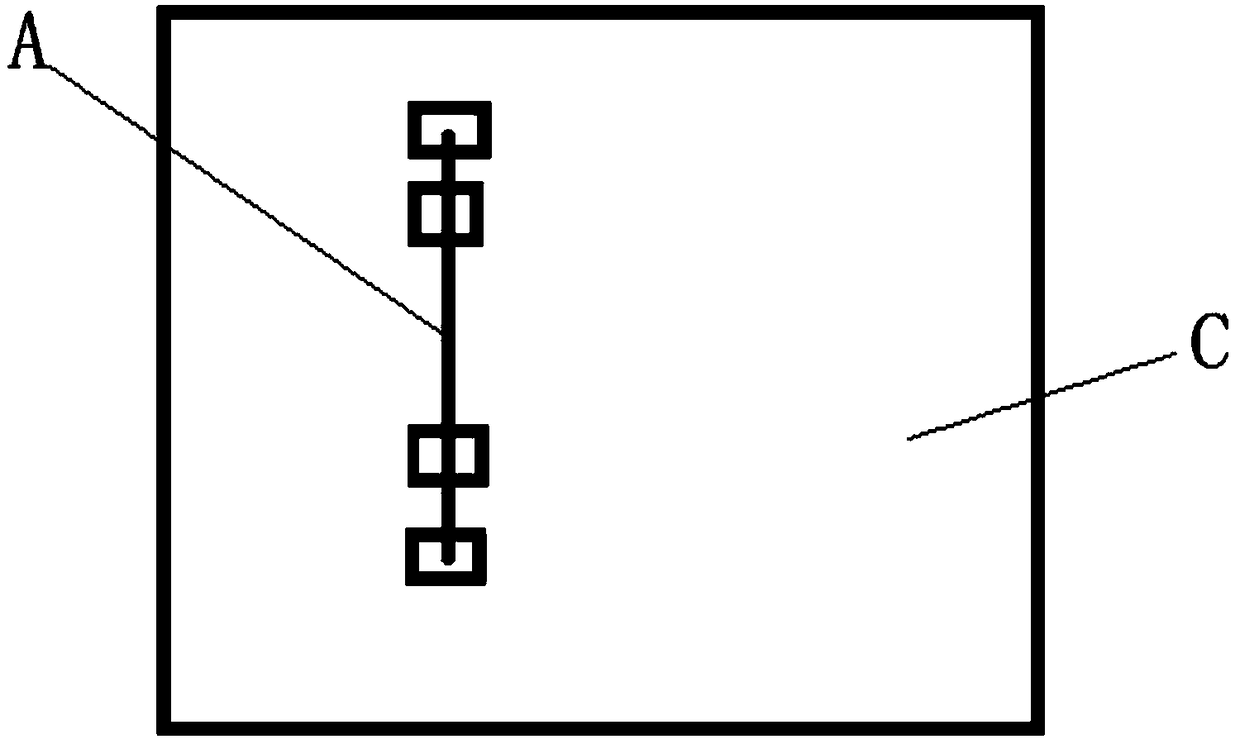

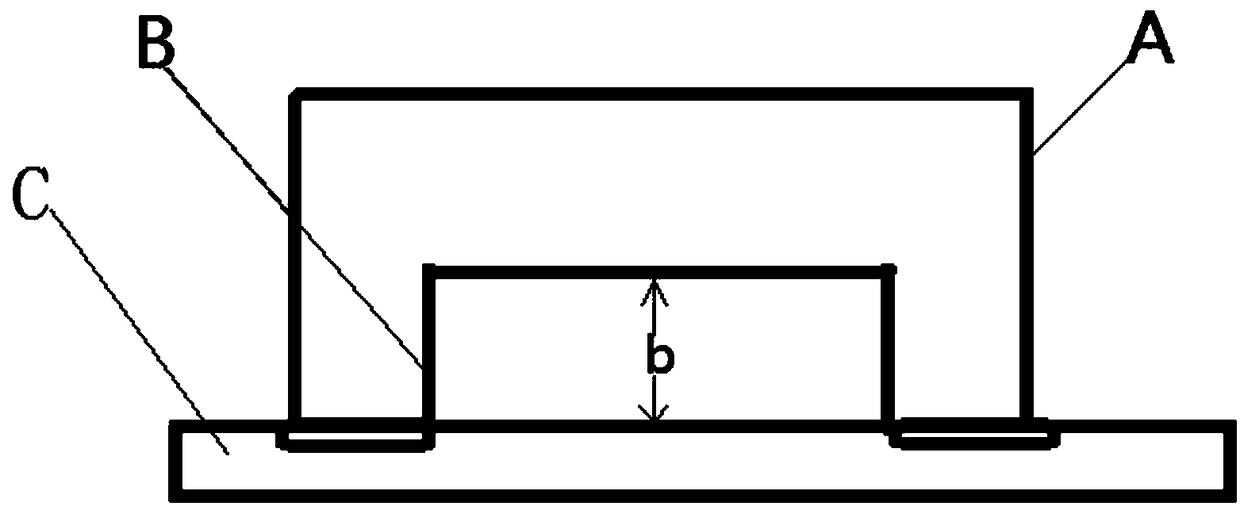

[0035] During the specific manufacture of the present invention, the horizontal and vertical distances and lengths between the first coupled inductance structure and the second coupled inductance structure (primary and secondary coils) are determined by the layout structure, inductance and coupling inductance coefficient during application, using three-dimensional electromagnetic field Simulation software aids design and implementation. Affected by integrated circuit devices and layout routing, often the metal coupling structure cannot be arranged in a regular shape to form the most reasonable positional relationship. The various embodiments of the present invention are only used as examples, and the influences of semiconductor devices and layout traces on the position and shape of the coupled inductor are ignored, and the description is made in principle. Theoretically, the structure of the present invention can bypass any semiconductor device and layout routing through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com