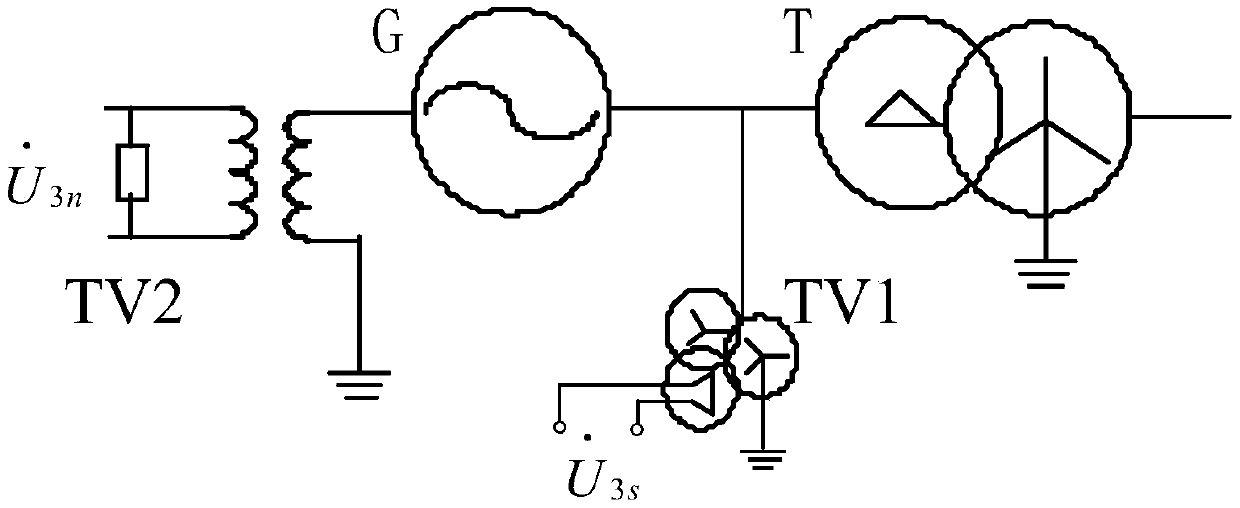

A highly sensitive third harmonic voltage differential stator ground protection method

A stator grounding protection and sub-harmonic technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of dead zone, many field malfunctions, dead zone, etc., to improve reliability, improve the scope of application, high The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

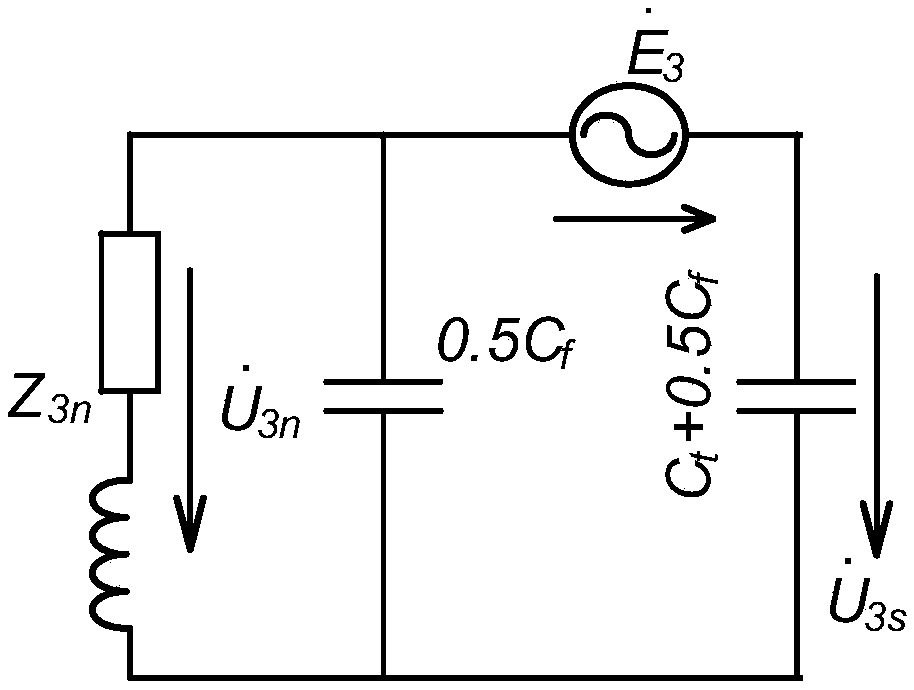

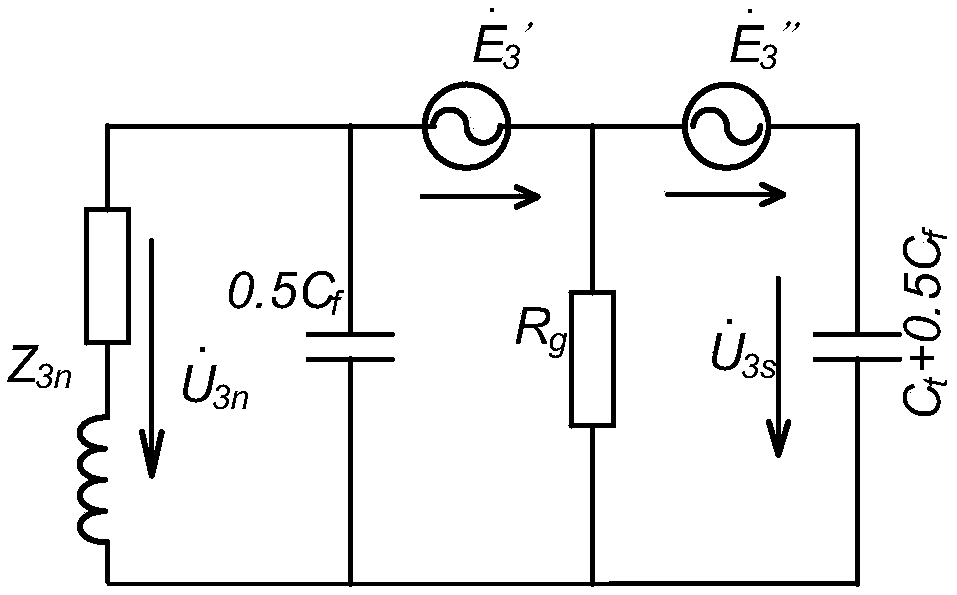

[0059] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0060] According to the parameters of a 300MW generator transformer set, a specific embodiment of the invention is provided. Required specific parameters: C f = 0.528μF, C t =0.348μF (including 0.3μF three-phase shock wave absorbing capacitor at the machine end), neutral point equivalent grounding resistance R when grounding is changed to grounding g =3636Ω, the change calculation memory time Δt needs at least 4 fundamental wave cycles, and Δt=80ms in this embodiment.

[0061] Step 1: The instantaneous value U of the neutral point zero sequence voltage of the generator n (k), the instantaneous value U of the terminal zero sequence voltage s (k), the instantaneous value U of the three-phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com