A method for manufacture a shield structure in a ribbon-shaped radio frequency transmission line/microstrip radio frequency transmission line

A technology of radio frequency transmission and shielding structure, applied in the fields of magnetic/electric field shielding, waveguide type devices, electrical components, etc., can solve the problems of transmission line interference, inability to achieve the shielding performance of coaxial lines, etc., and achieve the effect of improving shielding performance and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

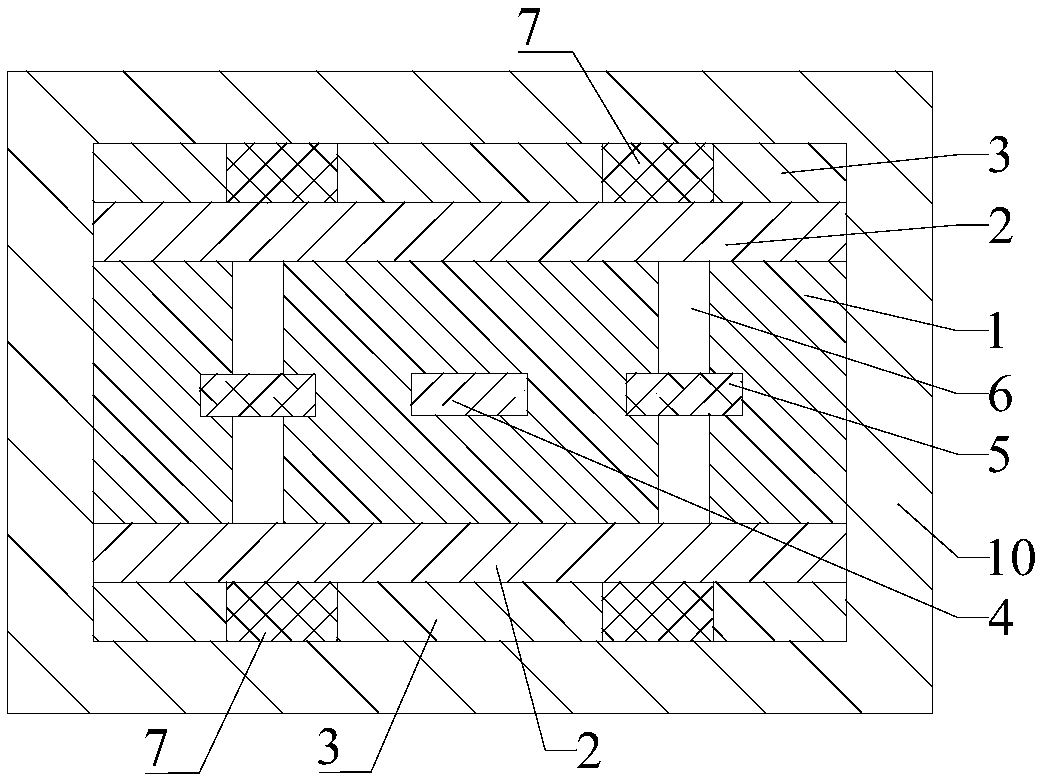

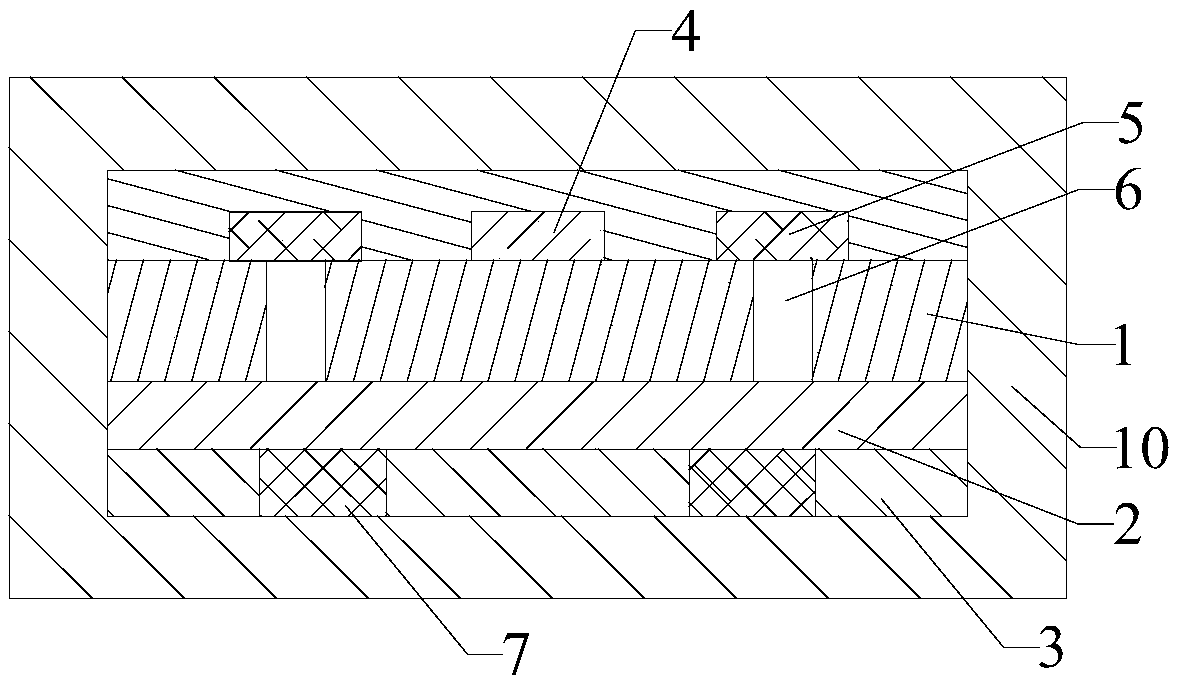

[0052] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention is: the strip radio frequency transmission line / microstrip radio frequency transmission line includes a base material layer 1, at least one side of the base material layer 1 is provided with a system formation 2, and the system formation 2 is far away from the base material One side of the layer 1 is provided with a protective layer 3, and the base material layer 1 is provided with a signal line 4. Optionally, the base material layer 1 is also provided with a ground wire 5 conducting with the system ground layer 2. ; Optionally, the ground wire 5 is connected to the system formation 2 through a ground hole 6 .

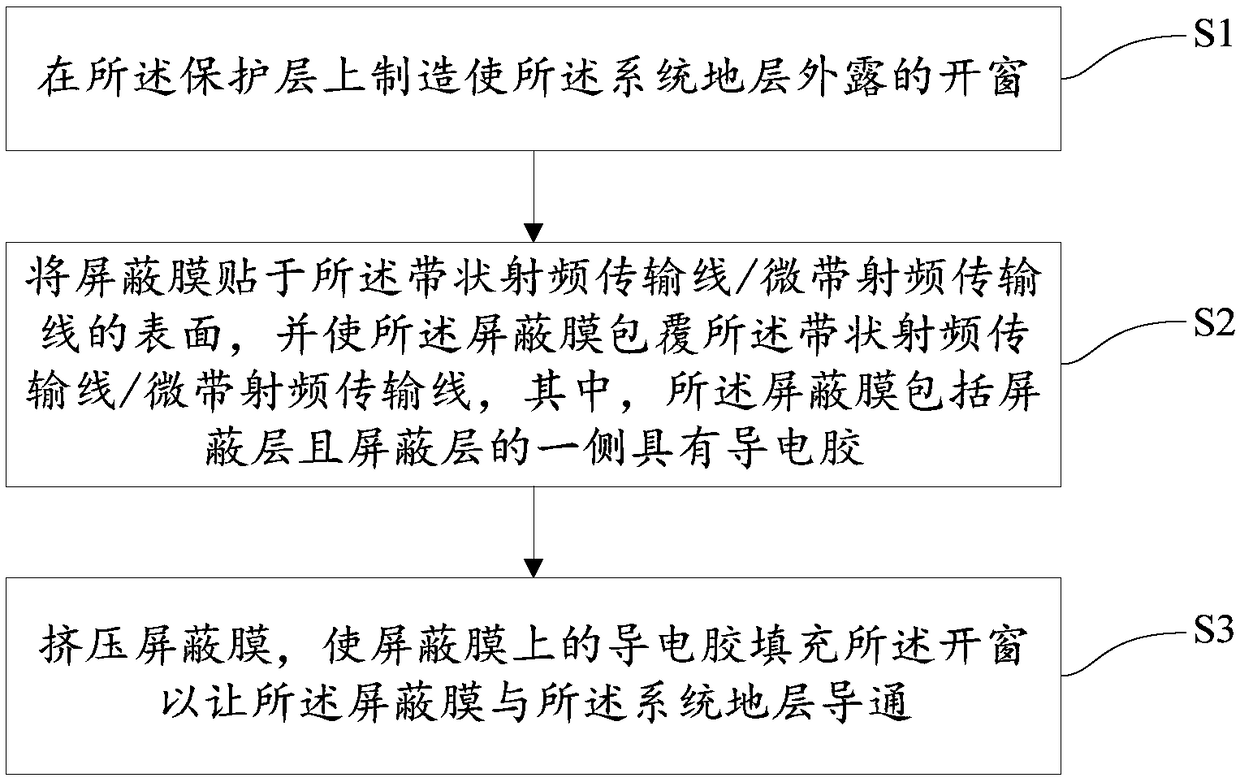

[0053] A method for manufacturing a shielding structure in a strip radio frequency transmission line / microstrip radio frequency transmission line, comprising the following steps,

[0054]S1: Making a window 7 on the protective layer 3 to expose the systematic formation 2;

[0055] S2...

Embodiment 2

[0064] Please refer to figure 1 , Figure 4 and Figure 5 , Embodiment 2 of the present invention is: the strip radio frequency transmission line / microstrip radio frequency transmission line includes a base material layer 1, at least one side of the base material layer 1 is provided with a system formation 2, and the system formation 2 is far away from the base material One side of the layer 1 is provided with a protective layer 3, and the base material layer 1 is provided with a signal line 4. Optionally, the base material layer 1 is also provided with a ground wire 5 conducting with the system ground layer 2. ; Optionally, the ground wire 5 is connected to the system formation 2 through a ground hole 6 .

[0065] A method for manufacturing a shielding structure in a strip radio frequency transmission line / microstrip radio frequency transmission line, comprising the following steps,

[0066] S1: Making a window 7 on the protective layer 3 to expose the systematic formation...

Embodiment 3

[0077] Please refer to figure 1 , Image 6 and Figure 7 , the third embodiment of the present invention is: the strip radio frequency transmission line / microstrip radio frequency transmission line includes a substrate layer 1, at least one side of the substrate layer 1 is provided with a system formation 2, and the system formation 2 is far away from the substrate One side of the layer 1 is provided with a protective layer 3, and the base material layer 1 is provided with a signal line 4. Optionally, the base material layer 1 is also provided with a ground wire 5 conducting with the system ground layer 2. ; Optionally, the ground wire 5 is connected to the system formation 2 through a ground hole 6 .

[0078] A method for manufacturing a shielding structure in a strip radio frequency transmission line / microstrip radio frequency transmission line, comprising the following steps,

[0079] S1: Making a window 7 on the protective layer 3 to expose the systematic formation 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com