A processing method for reducing the bitterness and astringency of Gongfu black tea

A processing method and technology for Gongfu black tea, which are applied in the processing field of reducing the bitterness and astringency of Gongfu black tea, can solve the problems of reducing the drinking value of black tea and the economic benefits of tea gardens, poor stability of black tea flavor and quality, lack of theoretical knowledge of producers, etc. And the effect of aroma purification, sweet and pure endoplasmic aroma, and tight shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

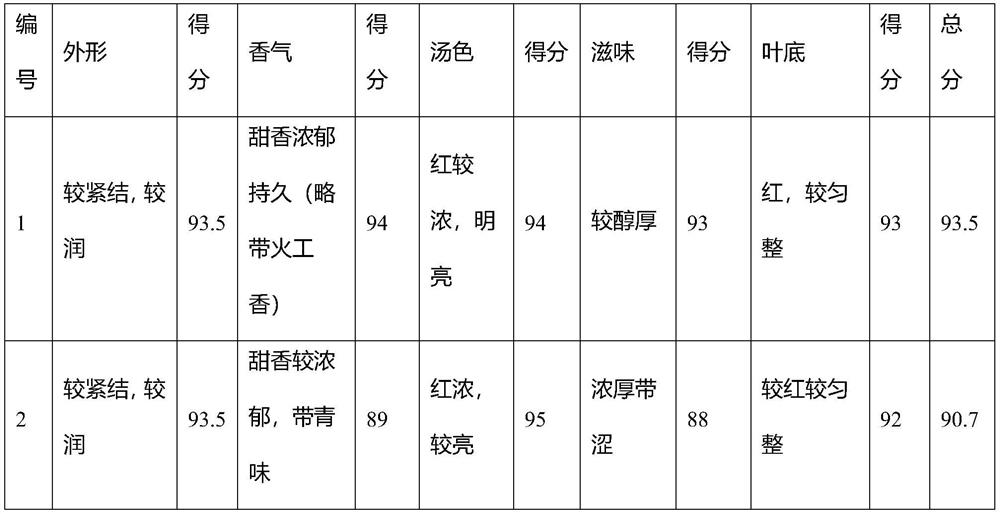

Embodiment 1

[0041]Pick the fresh leaves of one-bud and two-leaf tea trees of the Fuding Dabai variety in summer as raw materials, wither at room temperature until the mature leaves of the raw materials appear partially soft, and then shake the greens. The shaking speed is 500r / min, and the time is 3min. Put it until the buds and leaves are soft and the stems are broken continuously, and the water content is 58-60%, and the moderately withered leaves are obtained; put the withered leaves into the 6CR-50 kneading machine, and the kneading process is air-pressed for 0.5h→lightly pressed for 0.2h→ Medium pressure 0.2h→heavy pressure 0.1h→air pressure 0.1h→heavy pressure 0.1h→air pressure 0.1h, when the tea leaves are basically formed into strips and a small amount of tea juice is kneaded, the kneaded leaves are obtained; the kneaded leaves are sieved and then fermented For treatment, the thickness of stacked leaves is 30cm, the fermentation temperature is 28°C, and the relative humidity is 96%...

Embodiment 2

[0044] Pick the fresh leaves of the one-bud two-leaf tea tree of Fuding Dabai variety in autumn as raw materials, wither at room temperature until the mature leaves of the raw materials appear partially soft, and then shake the greens. The speed of shaking the greens is 550r / min, and the time is 2min. Put it until the buds and leaves are soft and the stems are broken continuously, and the water content is 58-60%, and the moderately withered leaves are obtained; put the withered leaves into the 6CR-50 kneading machine, and the kneading process is air-pressed for 0.5h→lightly pressed for 0.2h→ Medium pressure 0.1h→heavy pressure 0.1h→air pressure 0.1h→heavy pressure 0.1h→air pressure 0.1h, when the tea leaves are basically formed into strips and a small amount of tea juice is kneaded, the rolled leaves are obtained; the rolled leaves are sieved and then fermented For treatment, the thickness of stacked leaves is 40cm, the fermentation temperature is 30°C, and the relative humidit...

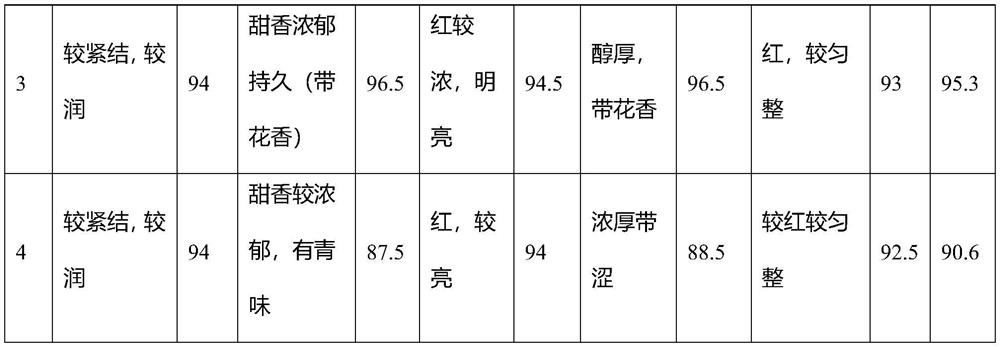

Embodiment 3

[0052] Pick the fresh leaves of the one-bud two-leaf tea tree of the Fuding Dabai variety in autumn as raw materials, wither at room temperature until the mature leaves of the raw materials appear partially soft, and then shake the greens. The speed of shaking the greens is 520r / min, and the time is 4min. Put it until the buds and leaves are soft and the stems are broken continuously, and the water content is 60-63%, and the moderately withered leaves are obtained; put the withered leaves into a 6CR-50 kneading machine, and the kneading process is air-pressed for 0.5h→lightly pressed for 0.2h→ Medium pressure 0.1h→heavy pressure 0.1h→air pressure 0.1h→heavy pressure 0.1h→air pressure 0.1h, when the tea leaves are basically formed into strips and a small amount of tea juice is kneaded, the rolled leaves are obtained; the rolled leaves are sieved and then fermented For treatment, the thickness of stacked leaves is 35cm, the fermentation temperature is 29°C, and the relative humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com