Green tea making method

A green tea and tea technology, applied in the field of agriculture, can solve the problems of different degrees of tea fiber tissue damage, tea quality reduction, tea quality is not high, to enhance the degradation transformation and soluble sugar substances, reduce the loss of aroma, tea integrity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

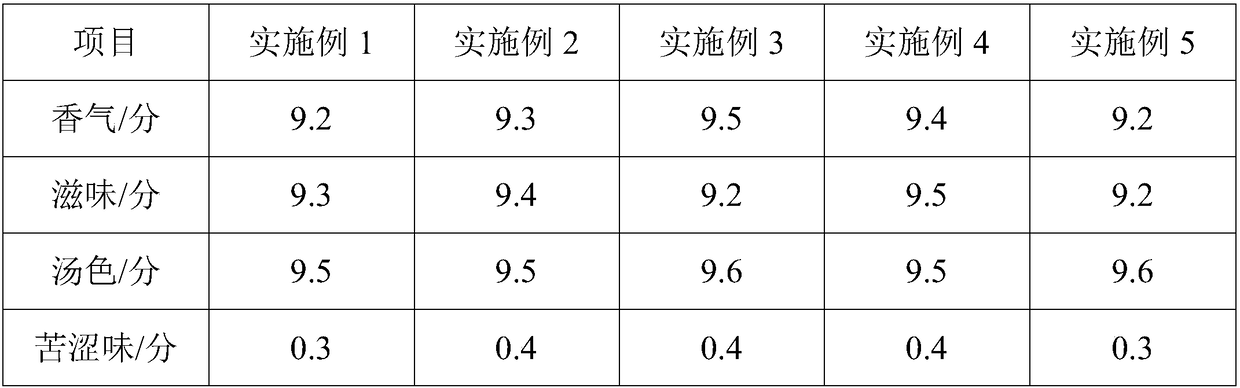

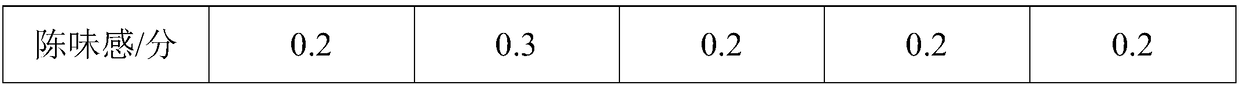

Examples

Embodiment 1

[0020] A preparation method of green tea, comprising the steps:

[0021] S1. Spread the fresh tea leaves for 2 hours at 30°C, with a thickness of 2cm, and then blow them with hot air at 25°C for 3 hours;

[0022] S2. Repeated fixing: put the tea leaves into the fixing machine, fix at 220°C for 4 minutes, then turn over at a frequency of 10 times / min for 30 minutes; fix at 150°C for 7 minutes, then at a frequency of 10 times / min for 50 minutes; fix at 95°C 12min, then flip at 15 times / min for 80min;

[0023] S3. Arrangement: send the tea into the arrangement mechanism;

[0024] S4. Drying: first turn and dry at 120°C to a moisture content of 15%, and then place it at 50°C to dry to a moisture content of 5%;

[0025] S5, Titian: use charcoal fire roasting method, Titian at 50℃ for 60min.

Embodiment 2

[0027] A preparation method of green tea, comprising the steps:

[0028] S1. Lay the fresh tea leaves at 20°C for 3 hours, the thickness of the leaves is 1cm, and then blow with hot air at 30°C for 1 hour;

[0029] S2. Repeated fixing: send the tea leaves into the fixing machine, fix at 240°C for 2 minutes, then turn over at a frequency of 20 times / min for 20 minutes; fix at 160°C for 4 minutes, then turn at a frequency of 25 times / min for 30 minutes; fix at 110°C 8min, then flip for 50min at a frequency of 30 times / min;

[0030] S3. Arrangement: send the tea into the arrangement mechanism;

[0031] S4. Drying: first turn and dry at 130°C to a moisture content of 10%, and then place it at 60°C to dry to a moisture content of 3%;

[0032] S5, Titian: use charcoal fire roasting method, Titian at 55℃ for 45min.

Embodiment 3

[0034] A preparation method of green tea, comprising the steps:

[0035] S1. Spread the fresh tea leaves for 2 hours at 28°C, with a thickness of 2cm, and then blow them with hot air at 26°C for 3 hours;

[0036] S2. Repeated fixing: send the tea leaves into the fixing machine, fix at 225°C for 4min, then turn at 12 times / min for 29min; fix at 152°C for 6min, then turn at 14 times / min for 46min; fix at 100°C 11min, then flip for 70min at a frequency of 20 times / min;

[0037] S3. Arrangement: send the tea into the arrangement mechanism;

[0038] S4. Drying: first turn and dry at 122°C to a moisture content of 14%, and then place it at 52°C to dry to a moisture content of 5%;

[0039] S5, Titian: use the charcoal fire roasting method, and Titian is 55min at 51℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com