Preparation method of BC dry powder extinguishing agent

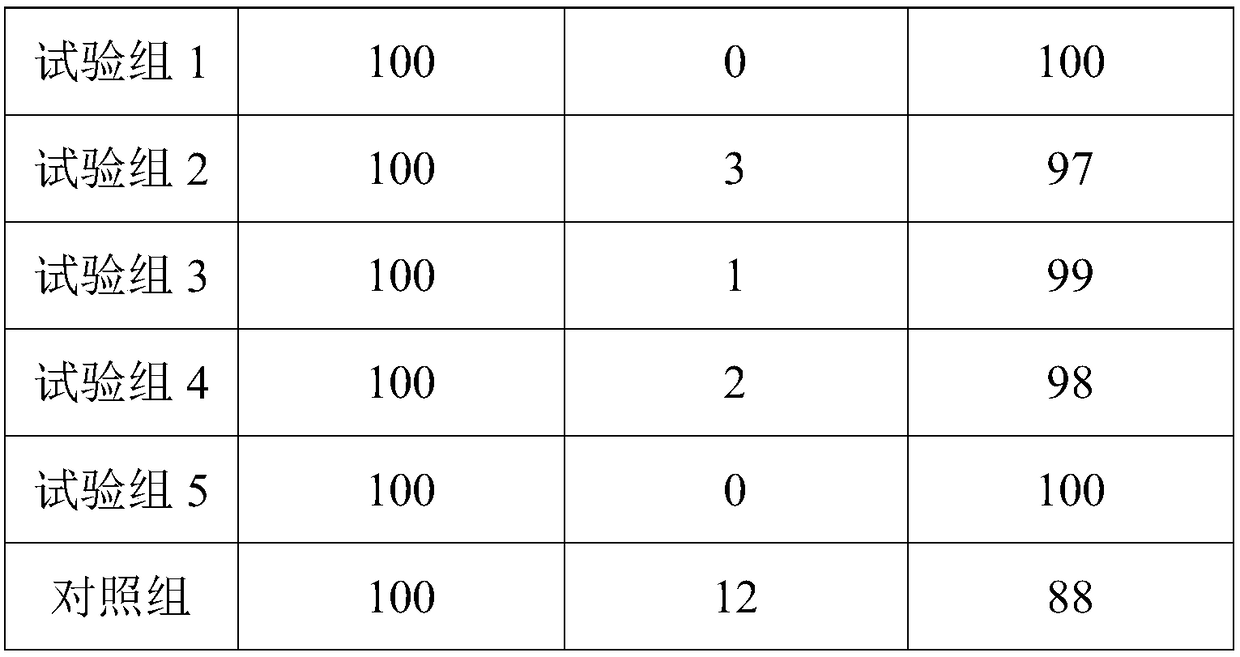

A technology of dry powder fire extinguishing agent and crushing aid, which is applied in fire protection equipment and other directions, can solve problems such as poor anti-re-ignition performance, and achieve the effects of strengthening hydrophobic performance, improving stability and improving anti-re-ignition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of preparation method of BC dry powder fire extinguishing agent, described preparation method comprises the steps:

[0019] S1. Mix the crushing aid and monoammonium phosphate evenly, and crush until more than 90% of the particles in the mixture have a particle size smaller than 6um to obtain a base material;

[0020] S2. Add hydrophobic white carbon black to the base material, stir once, heat up to 58°C, add polyether modified silicone surfactant, stir twice, heat up to 109°C, stir three times, stir four times to obtain BC dry powder Extinguishing agent.

Embodiment 2

[0022] A kind of preparation method of BC dry powder fire extinguishing agent, described preparation method comprises the steps:

[0023] S1. Mix the crushing aid and monoammonium phosphate evenly, and crush until more than 90% of the particles in the mixture have a particle size smaller than 6um to obtain a base material;

[0024] S2. Add hydrophobic white carbon black to the base material, stir once, heat up to 63°C, add polyether modified silicone surfactant, stir twice, heat up to 112°C, stir three times, stir four times to obtain BC dry powder Extinguishing agent;

[0025] Among them, in S1, the crushing aid is composed of mica powder and silica powder in a mass ratio of 1:1.

Embodiment 3

[0027] A kind of preparation method of BC dry powder fire extinguishing agent, described preparation method comprises the steps:

[0028] S1. Mix the crushing aid and monoammonium phosphate evenly, and crush until more than 90% of the particles in the mixture have a particle size smaller than 6um to obtain a base material;

[0029] S2. Add hydrophobic white carbon black to the base material, stir once, heat up to 60°C, add polyether modified silicone surfactant, stir twice, heat up to 110°C, stir three times, stir four times to obtain BC dry powder Extinguishing agent;

[0030] Among them, in S1, the crushing aid is composed of mica powder and silica powder in a mass ratio of 1:1;

[0031] In S2, hydrophobic silica is obtained by modifying silica with alkoxy silicone oil;

[0032] In S2, the primary stirring speed is 2000r / min, and the primary stirring time is 25min;

[0033] In S2, the secondary stirring speed is 1800r / min, and the secondary stirring time is 25min;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com