Vertical high-speed small horizontal screw centrifuge

A decanter centrifuge, high-speed technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve problems such as low work efficiency, noise pollution, and insufficient safety, and achieve high work efficiency, reduce noise pollution, The effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

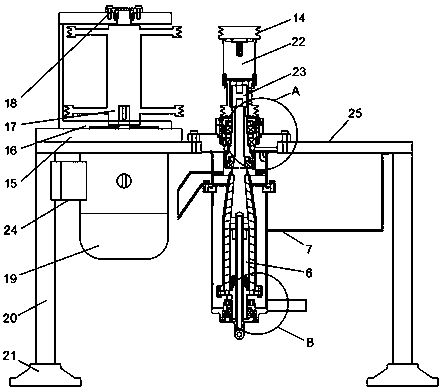

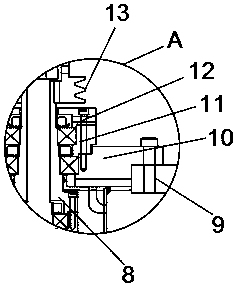

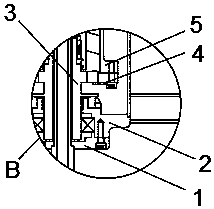

[0019] Embodiment one, by figure 1 , figure 2 with image 3 Given, the present invention includes a support platform 25, one side of the support platform 25 is provided with a motor 19, the motor 19 is controlled by an external switch, and the motor 19 and the support platform 25 are connected through a motor adjustment seat 15, which is convenient for adjusting the motor 19 Simple and convenient, the top of motor 19 is provided with belt support frame 16, and belt support frame 16 is provided with motor belt 17, and one end of motor 19 is provided with pulley, is connected by pulley bearing between pulley and motor 19, and pulley bearing and belt support frame The junction of 16 is provided with belt pulley bearing cover 18, rotates by motor 19 during use, drives belt pulley bearing and my pulley to rotate, then drives spiral belt pulley 14 and bowl belt pulley 13 by motor belt 17, promptly can have fast driving screw 6 and The rotating drum 5 is simple and convenient, and...

Embodiment 2

[0021] Embodiment two, on the basis of embodiment one, by figure 1 Provided, the bottom end of the support platform 25 is provided with a support foot 20, the bottom end of the support foot 20 is provided with a shock absorber 21, and the bottom end of the shock absorber 21 is provided with anti-slip lines, the depth of the anti-slip lines is ten centimeters, and the anti-slip lines Arranged in a circular shape, the support feet 20, shock absorbing pads 21 and anti-skid lines are used to make the whole more stable.

Embodiment 3

[0022] Embodiment three, on the basis of embodiment one, by Figure 5 Provided, the motor 19 and the supporting foot 20 are connected through a support plate 24, and the inside of the support plate 24 is provided with a shock absorbing chamber 2401, and the inside of the shock absorbing chamber 2401 is provided with a shock absorbing spring 2402, and one side of the shock absorbing spring 2402 is provided There are reinforcing ribs 2403, which can make the motor 19 more stable through the support plate 24 during use. noise pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com