Intelligent fixed weight and fixed length on-line control system of continuous casting billet

A control system and continuous casting slab technology, applied in the field of iron and steel metallurgy, can solve problems such as changes in casting speed and superheat without considering continuous casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with the accompanying drawings.

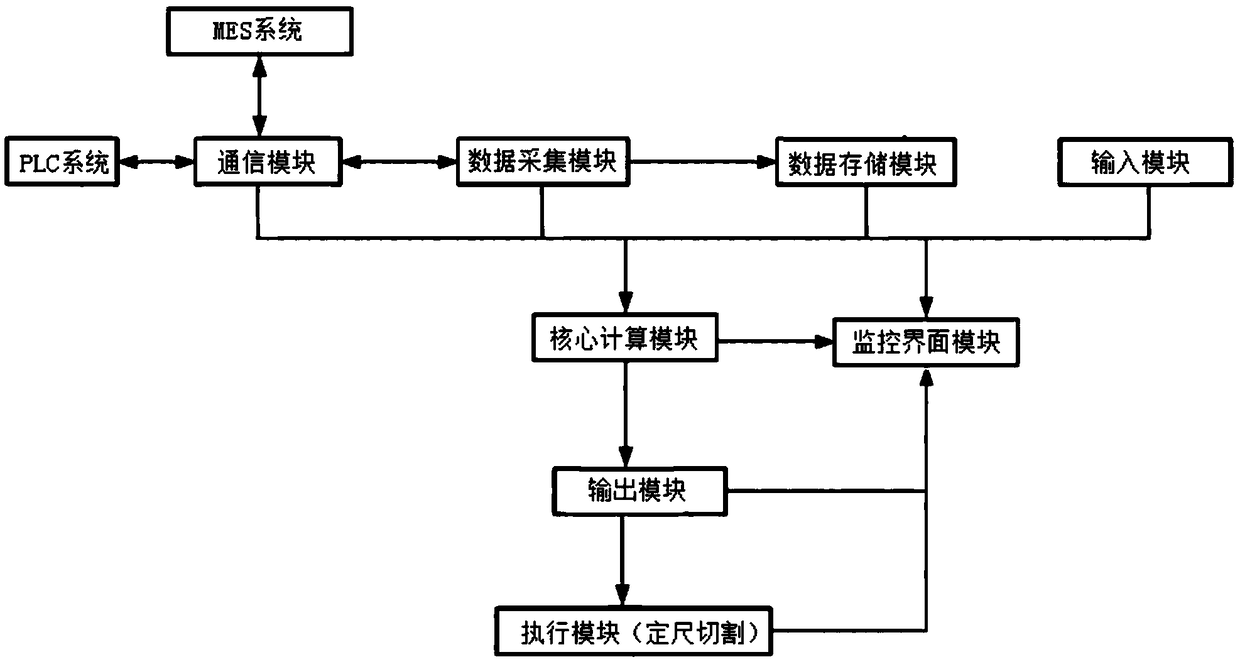

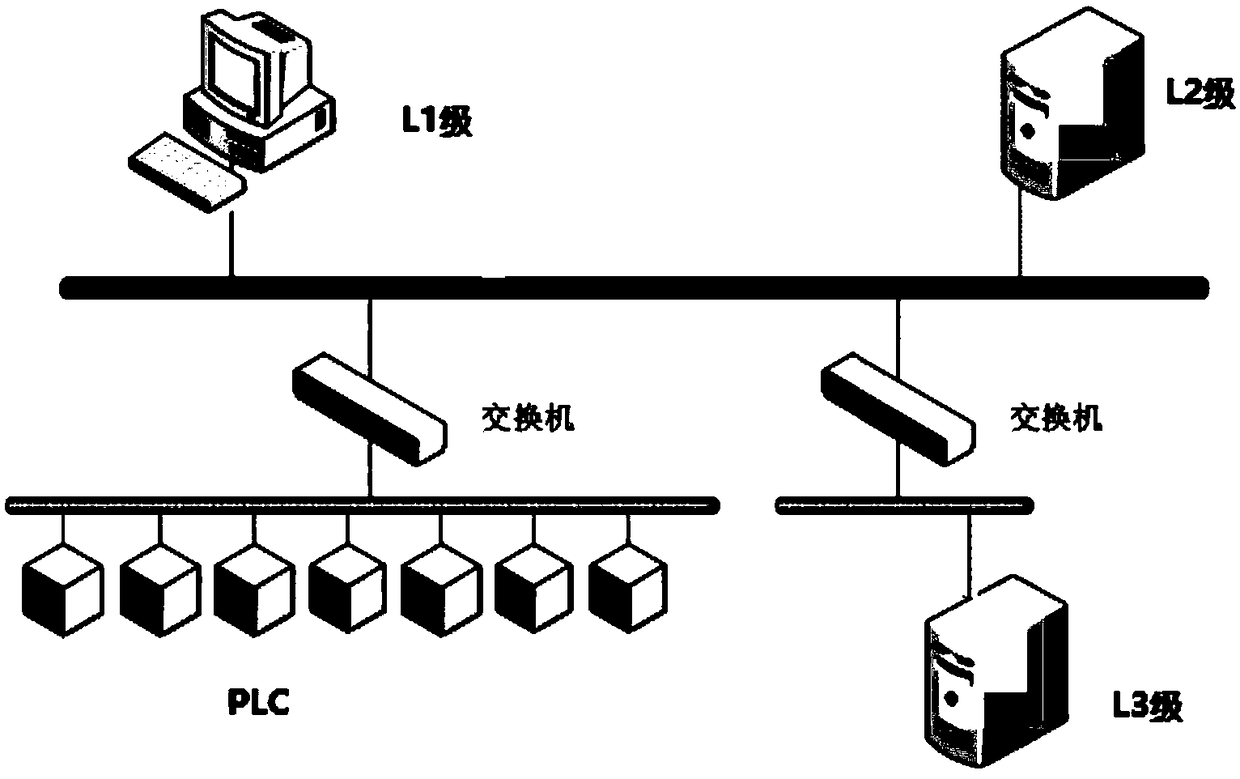

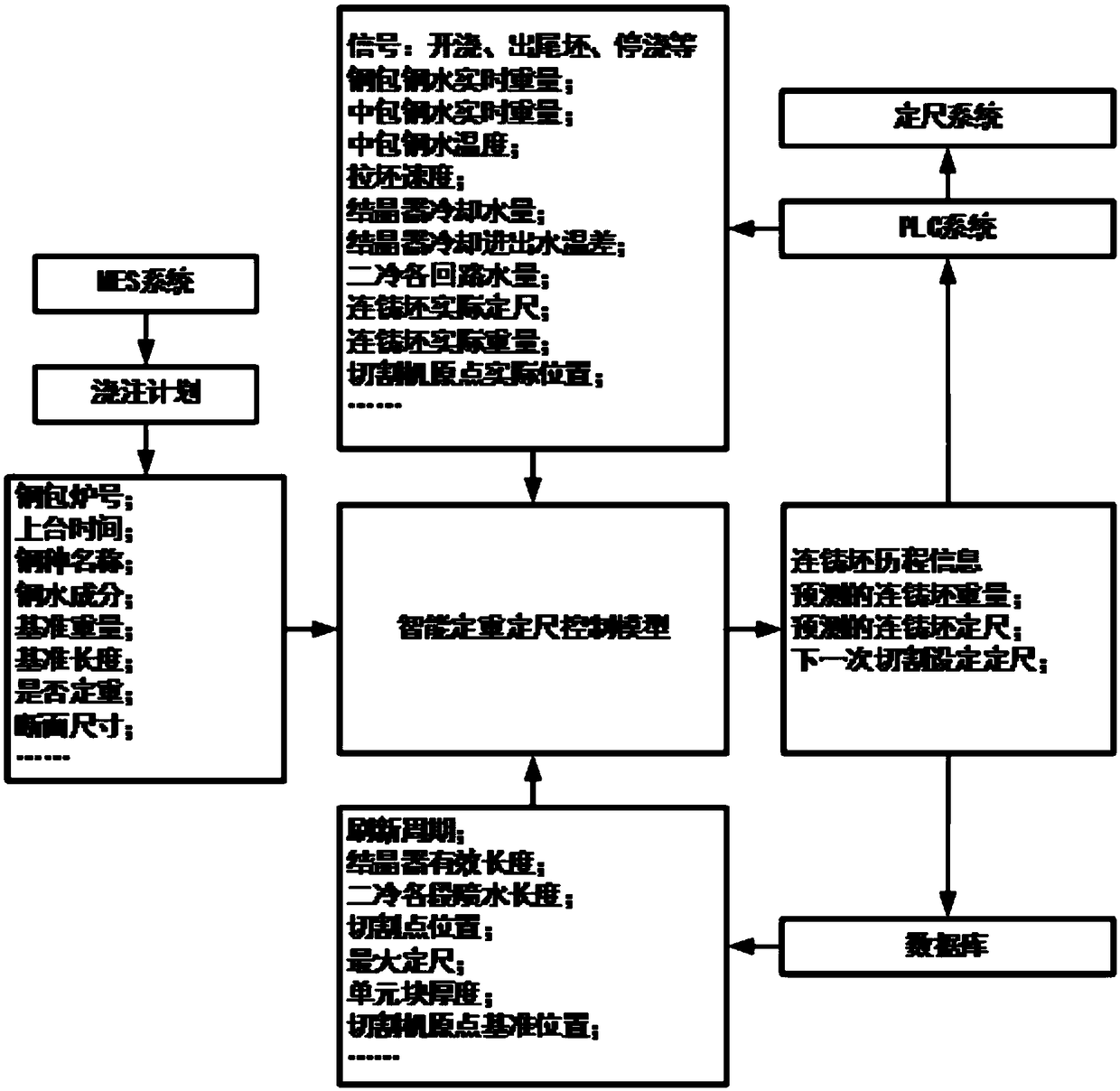

[0084] The continuous casting slab intelligent weighing and sizing online control system is a new technology integrating weighing system, production process data tracking, machine learning, mathematical model and intelligent control. Such as figure 1 As shown, the present invention is mainly composed of an input module, a data acquisition module, a data storage module, a communication module, a core calculation module, an output module, an execution module and a monitoring interface module. The data acquisition module is connected with the data storage module and the core computing module. The data acquisition module continuously collects the real-time production process information of the continuous casting slab, the homing deviation of the cutting machine, and the weighing of the continuous casting slab after cutting. The information collected by the data acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com