A method for replacing aircraft engine blades

An aircraft engine and blade technology, which is applied in the field of aircraft engine blade replacement, can solve the problems of easy damage to the blade, no blade maintenance and replacement, affecting the reliable operation of the engine, etc., and achieves the effect of good technical support and restoration of reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A method for replacing an aircraft engine blade, comprising the steps of:

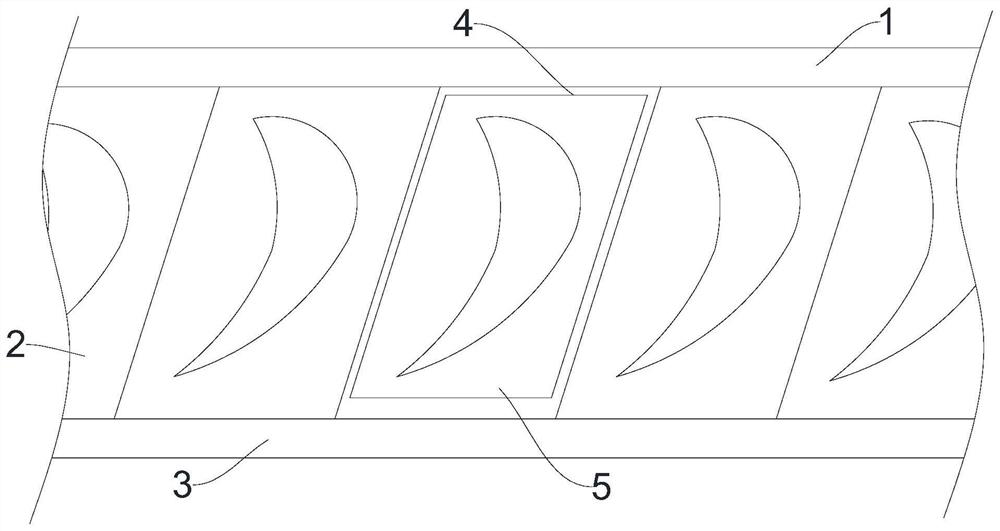

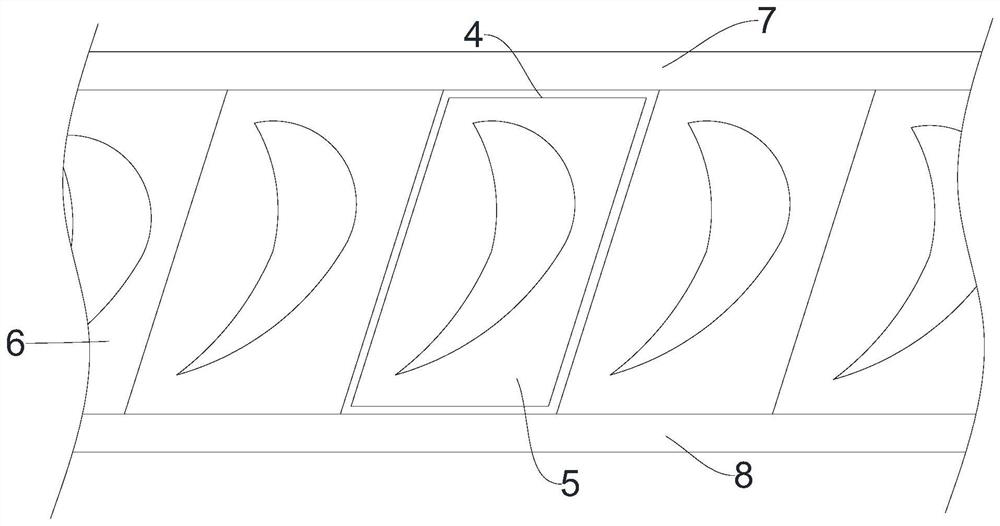

[0029] Step 1: Cut the defective low-pressure turbine guide blades on the welding assembly of the low-pressure turbine guide that need to be replaced by EDM, and the cutting method is as follows: figure 1 As shown, there are a total of 8 slits 4. In order to keep the margin of solder grinding, the distance between the slits 4 at the butt weld of the upper edge plate 6 and the lower edge plate 2 of the blade is 1-1.5 mm, the distance between the front ring 1, the front mounting edge 7 and the rear mounting edge 8 and the butt weld of the blade respectively 4 is 1-1.5mm from the brazing seam on the side of the blade, along the exhaust edge to the lower edge of the blade The depth of the slit 4 in the vertical direction of the rear ring groove of the flange of the plate 2 is 3.5-4mm, in order to avoid damage to the overlapping of the flange of the blade and the rear ring groove of the welded assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com