Equipment for continuously producing regenerated solid wood plain panels

A technology of solid wood veneer and equipment, which is used in the joining of wooden veneers, wood processing appliances, and other plywood/plywood appliances, etc., can solve the problems of high processing cost and low utilization rate, and achieve the improvement of utilization rate and reduction of resources. the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

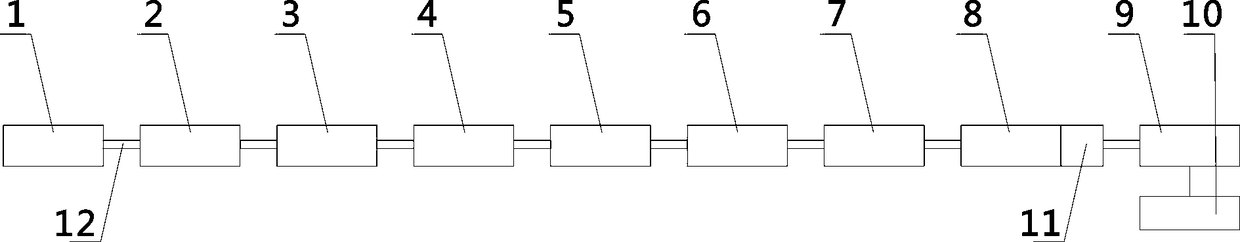

[0011] Example 1. See attached figure 1 , A continuous production of recycled solid wood veneer equipment includes: construction waste wood strip cement impurity removal machine 1, construction waste wood strip thickness and width classification machine 2, right-angle straight saw 3, comb machine 4, automatic lengthening machine 5. Solid wood strip cutting machine 6, automatic gluing machine 7, multi-layer four-sided side pressure hot press 8, recycled wood sanding machine 9, plate turning machine 10, hydraulic lifting storage machine 11, roller table 12, which are characterized by: The discharge port of the construction waste wood strip cement impurity removal machine is connected with the feed opening of the construction waste wood strip thickness and width sorter through a roller table, and the discharge port of the construction waste wood strip thickness width sorter passes through the roller table and the right-angle saw The feed port of the right-angle saw is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com