High composite strength VMPET film for medicine packaging

A technology for composite strength and packaging, applied in the field of film manufacturing, can solve the problems of lack of heat sealing performance, low composite strength of composite layers, and reduced composite strength, so as to reduce customer complaints, expand the application market, and increase economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

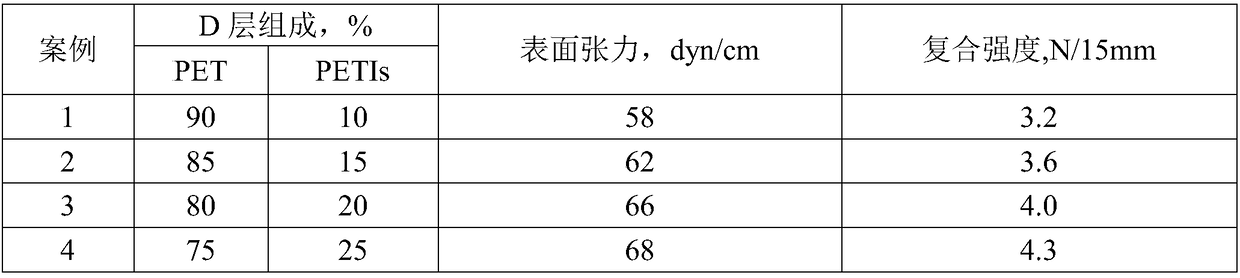

[0027] A / B / C / D (90%PET+10%PETIs), A layer is aluminum layer, the thickness is 450 angstroms, B layer is the aluminum layer of PET, the thickness ratio is 15%; C layer is the core layer of PET , with a thickness ratio of 65%; layer D is a modified PET layer, comprising 90% of PET and 10% of PETIs, with a thickness ratio of 20%.

[0028] By adopting the above technical scheme, the surface tension of the non-aluminized surface of the obtained VMPET film is 58dyn / cm, which is 30% higher than that of the untreated one, and the composite strength after compounding with PE can reach 3.2N / 15mm.

Embodiment 2

[0030] A / B / C / D (85%PET+15%PETIs), A layer is aluminum layer, the thickness is 450 angstroms, B layer is the aluminum layer of PET, the thickness ratio is 15%; C layer is the core layer of PET , the thickness ratio is 65%; the D layer is a modified PET layer, which contains 85% PET and 15% PETIs, and the thickness ratio is 20%.

[0031] By adopting the above technical scheme, the surface tension of the non-aluminized surface of the obtained VMPET film is 62 dyn / cm, which is 40% higher than that of the untreated one, and the composite strength after compounding with PE can reach 3.6N / 15mm.

Embodiment 3

[0033] A / B / C / D (80%PET+20%PETIs), layer A is aluminum layer with a thickness of 450 angstroms, layer B is the aluminum layer of PET with a thickness ratio of 15%; layer C is the core layer of PET , the thickness ratio is 65%; the D layer is a modified treatment layer of PET, which contains 80% PET and 20% PETIs, and the thickness ratio is 20%.

[0034] By adopting the above technical scheme, the surface tension of the non-aluminized surface of the obtained VMPET film is 66 dyn / cm, which is 50% higher than that of the untreated one, and the composite strength after compounding with PE can reach 4.0N / 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com