An intelligent tire frame and a method for supporting a ship hull by the intelligent tire frame

A technology of intelligent tire frame and hull, applied in ship parts, ship construction, ship design, etc., can solve the problems of indirect economic loss, consumption of large manpower and material resources, and waste of manpower and material resources in shipyards, so as to shorten the construction period and save manpower. , the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

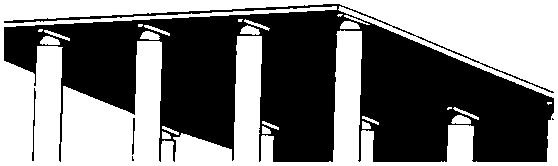

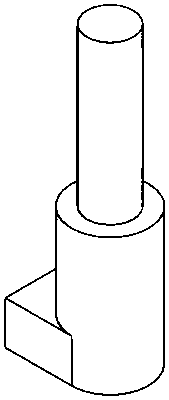

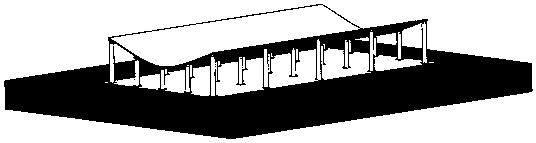

[0046] A kind of intelligent tire rack, comprising: such as figure 1 The mechanical pusher device shown and the figure 2 The perforated plate lateral stabilizer shown,

[0047]The mechanical push rod device includes at least 2 rows and 2 columns of tire pillars evenly arranged and the working units attached to each tire pillar. The mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com