Method for treating wastewater in production of p-nitrobenzoic acid

A technology for p-nitrobenzoic acid and waste water production, which is used in water/sewage treatment, natural water treatment, heating water/sewage treatment, etc., and can solve problems such as high operating costs, difficult to solve biochemical total nitrogen problems, and poor equipment stability. , to achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

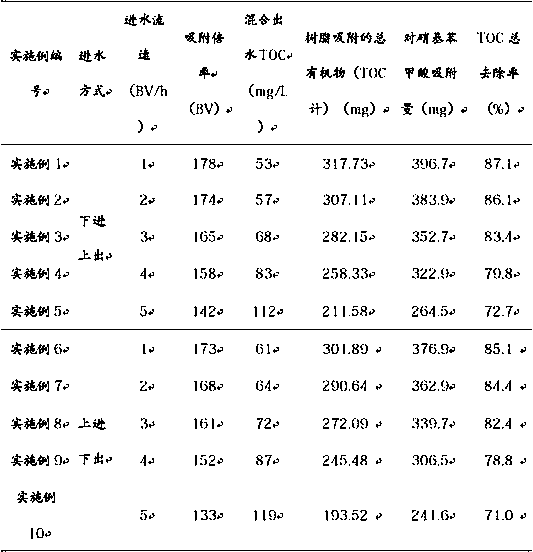

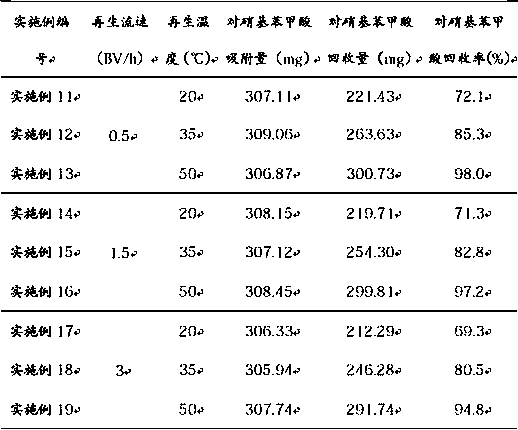

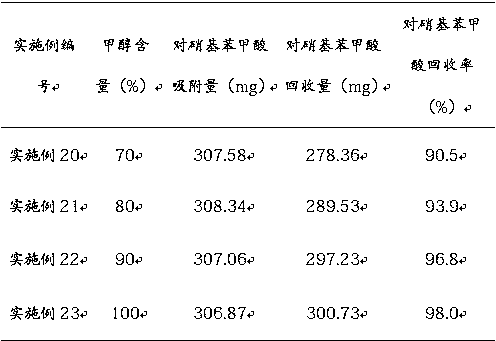

[0029] Below in conjunction with specific embodiment the present invention is described in further detail:

[0030] The p-nitrobenzoic acid production wastewater of an enterprise in Zhejiang, the main organic component is p-nitrobenzoic acid, TOC=410 mg / L, the concentration of nitric acid is 5%, and there are traces of suspended particles.

[0031] Proceed as follows:

[0032] ①Take 1000mL of waste water and filter until completely clarified;

[0033] ②Put 5mL resin into the chromatography column, rinse with 50mL water until clear;

[0034] ③The filtered water sample is pumped into the resin column, and the flow rate is controlled at 1-5BV / h. When the TOC of the effluent water rises to just over 123mg / L, the water intake is stopped (at this time, the removal rate of TOC in the raw water by the resin is less than 70%). And according to the total TOC value of the resin effluent, the adsorption amount of organic matter and the TOC removal rate of the resin were calculated, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com