Epoxy resin chemical industry paint production technology

A technology of epoxy resin and production process, which is applied in the field of coating processing, can solve the problems of small stirring range, low stirring efficiency, and small heat exchange area, and achieve the goals of increasing heat exchange area, avoiding secondary cleaning, and improving stirring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

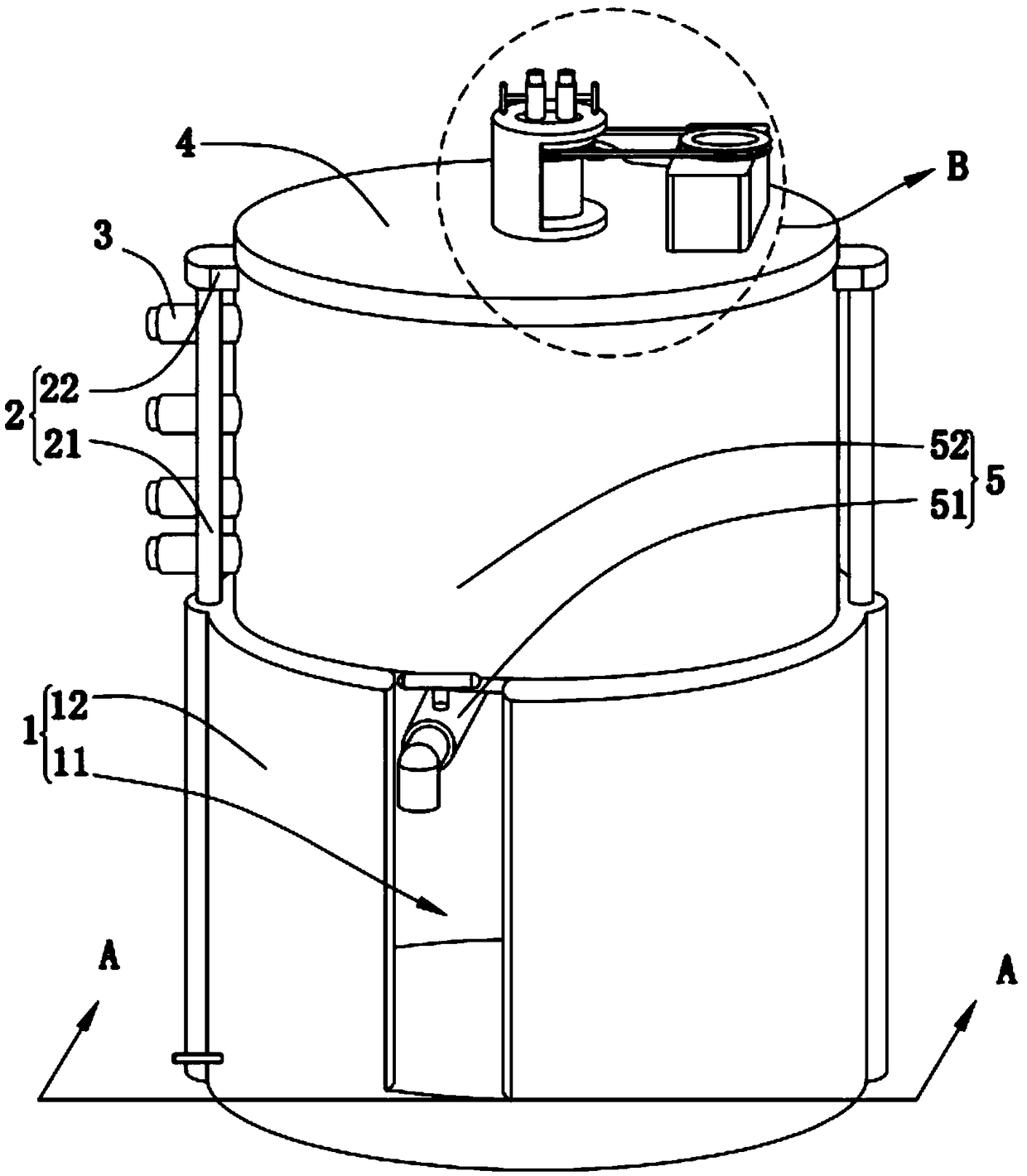

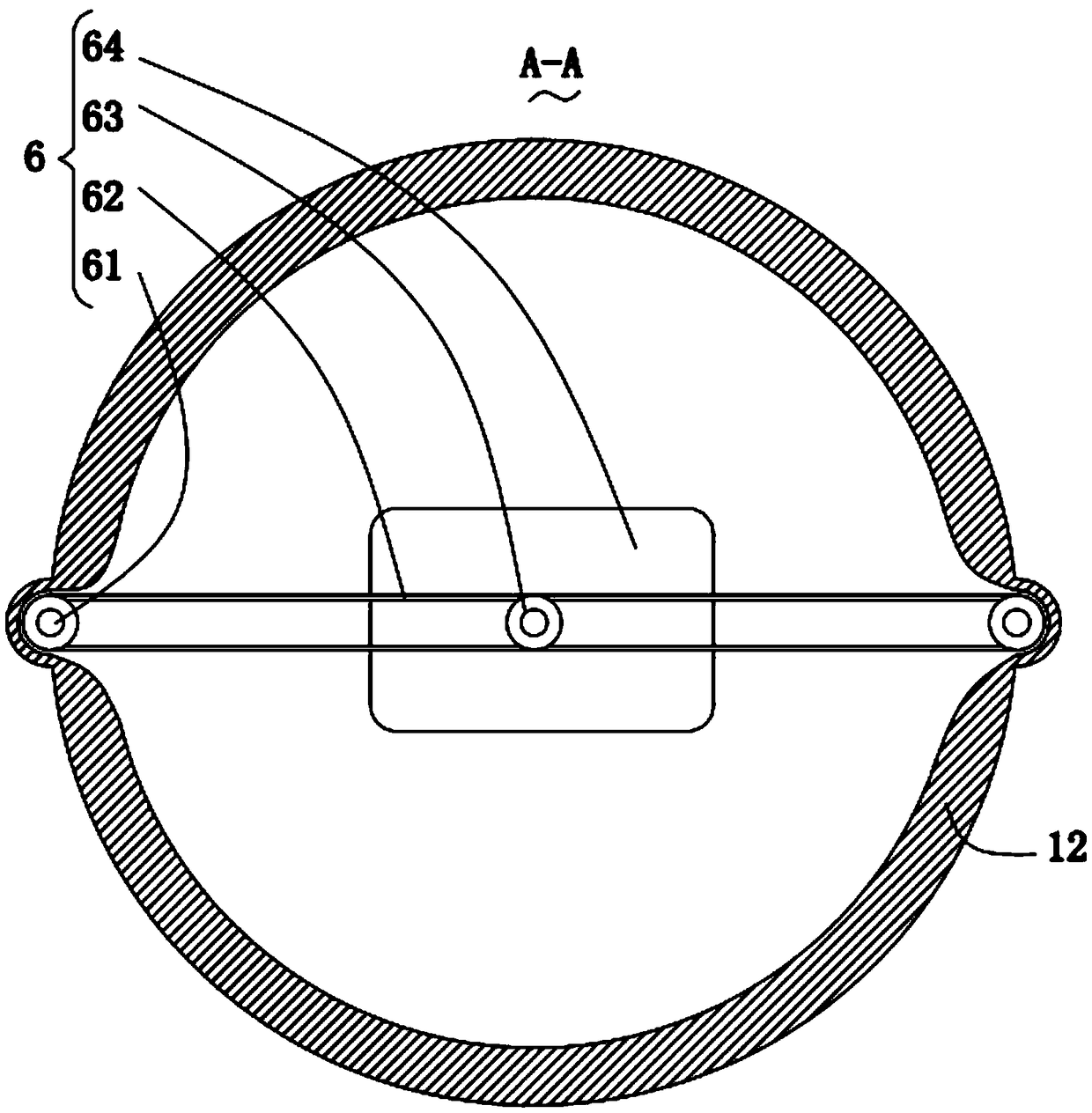

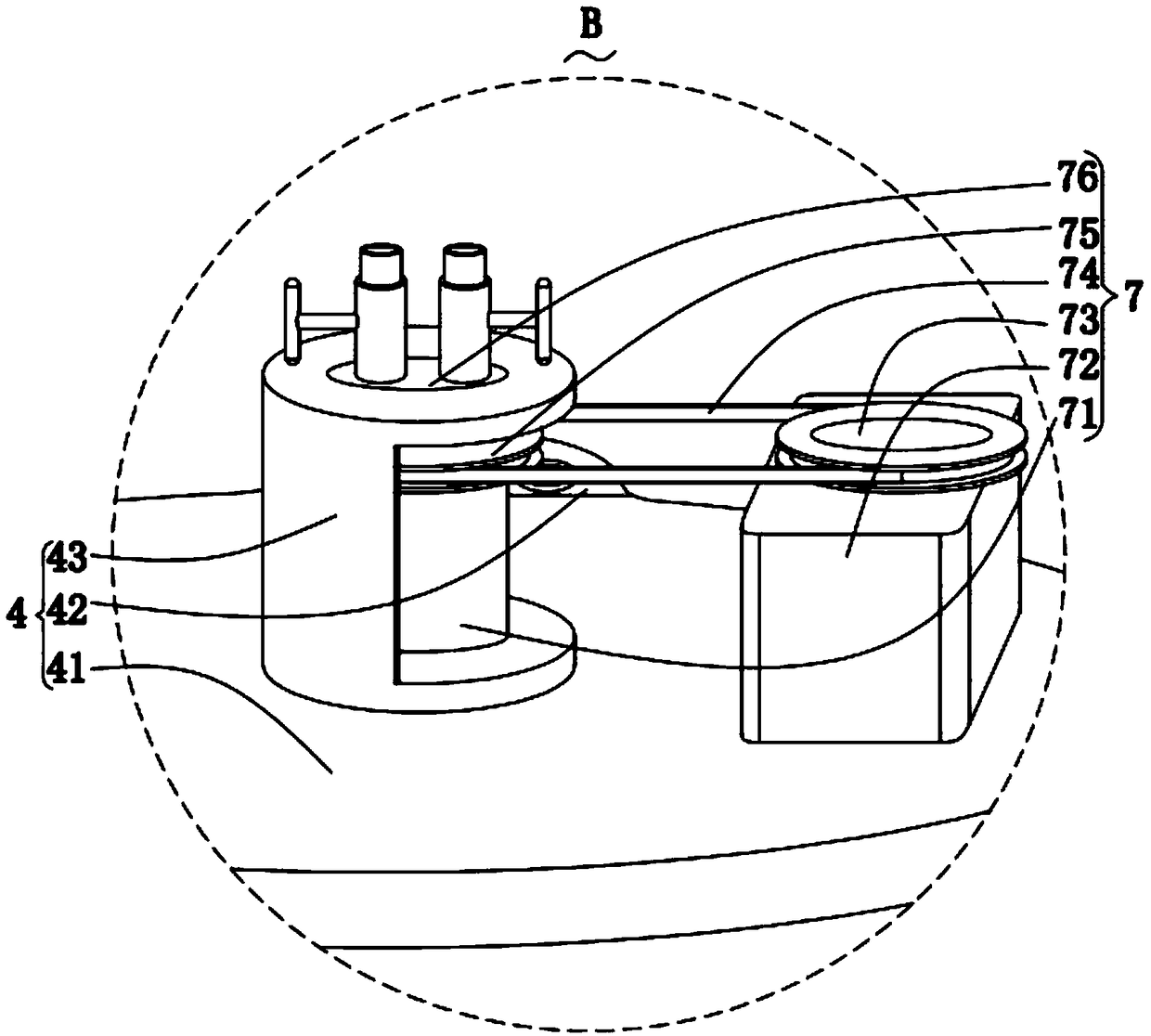

[0032] Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 Shown, a kind of epoxy resin chemical coating production technique of the present invention, this technique comprises the following steps:

[0033] S1, take epoxy resin GELR-128 (epoxy equivalent is 190), reactive diluent BGE (epoxy equivalent is 190) or D-1214 and curing agent H-113;

[0034] S2, putting the raw materials in S1 into an emulsifier for emulsification;

[0035] S3, put the paint emulsified in S2 into a bucket, and set aside;

[0036] The emulsifying machine adopted in this process includes a storage structure 1, a guiding structure 2, four valves 3, a sealing structure 4, an emulsifying structure 5, a driving structure 6, a stirring structure 7, a first c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap