A method for preparing aluminum samarium master alloy by sinking cathode molten salt electrolysis

A molten salt electrolysis and intermediate alloy technology, applied in electrolysis components, electrolysis process, electrodes, etc., can solve the problems of manpower consumption, difficulty in electrolytic cell design, etc., and achieve the effect of reducing Sm content and current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

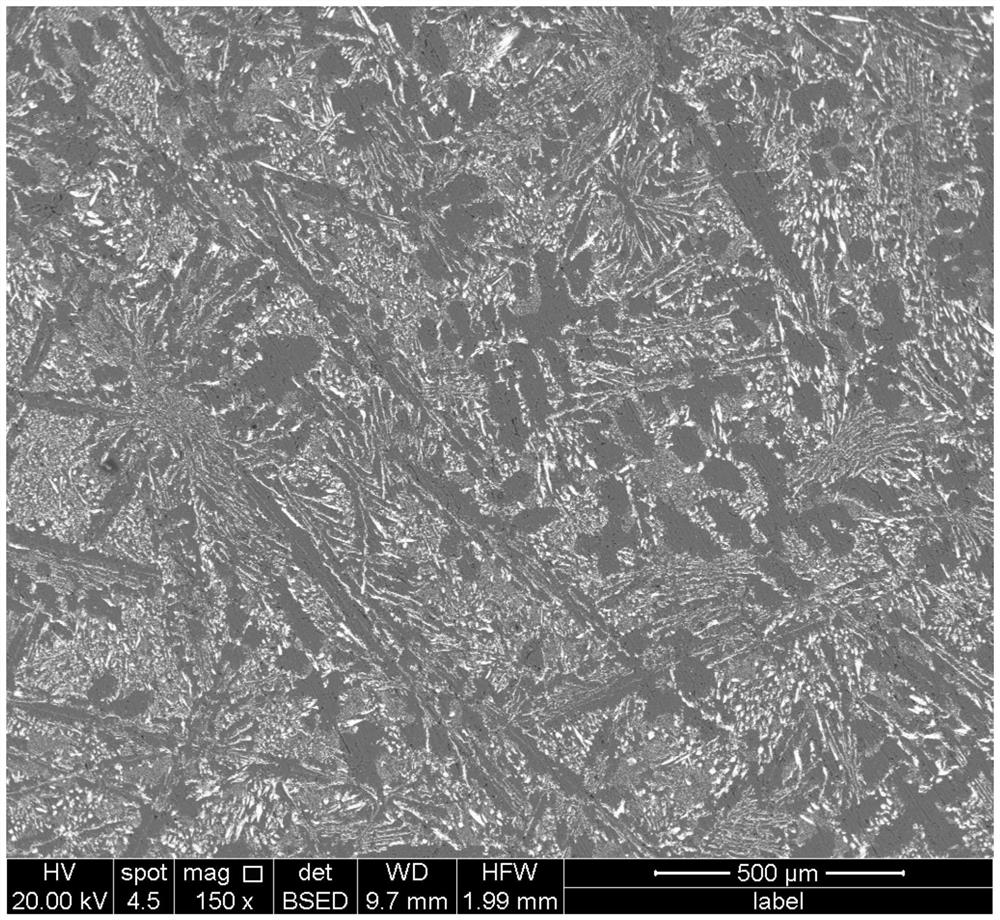

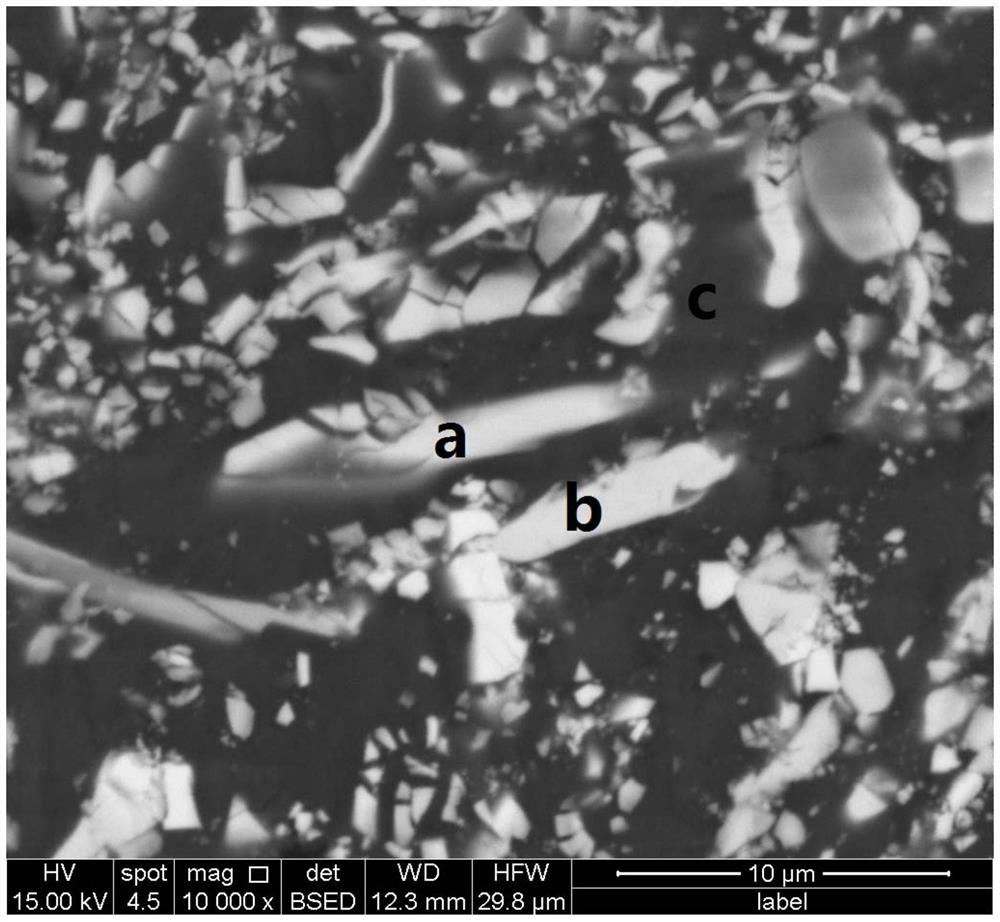

Image

Examples

Embodiment

[0029] A method for preparing an aluminum samarium master alloy by sinking cathode molten salt electrolysis, comprising the following steps:

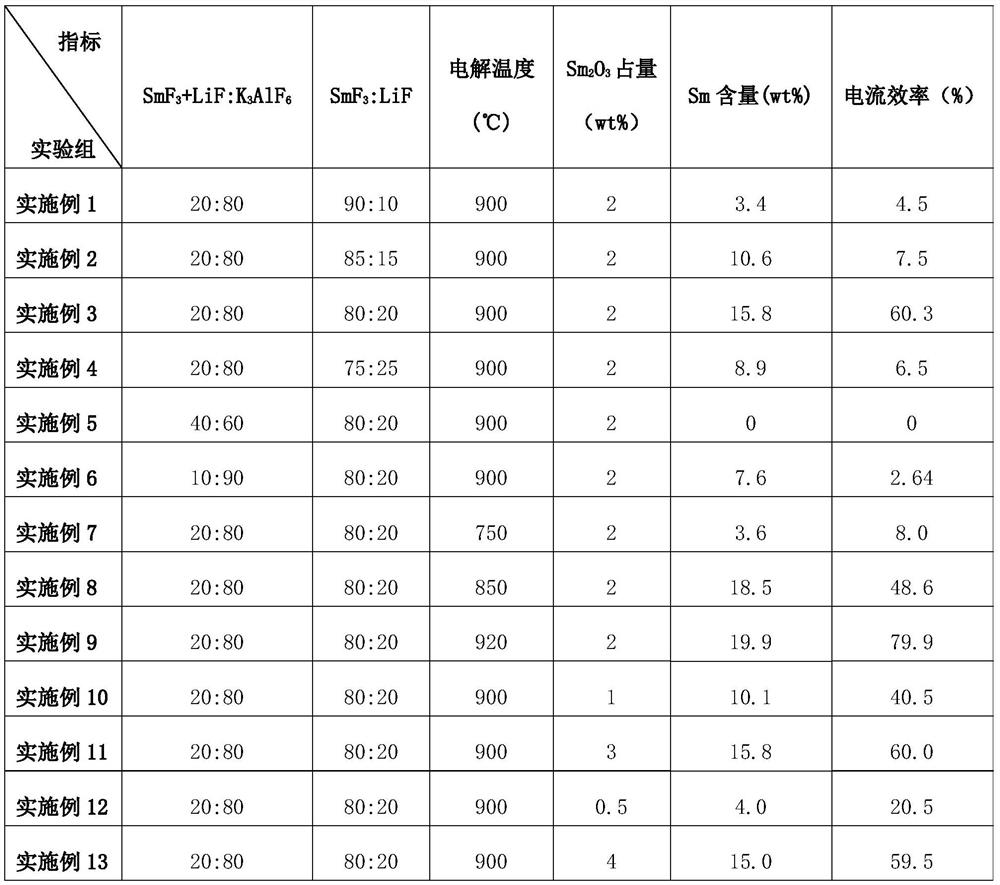

[0030] (1) Weigh the raw materials respectively: SmF 3 , LiF, K 3 AlF 6 、Sm 2 o 3 , aluminum ingots, to ensure that the mass ratio of raw materials is: (SmF 3 +LiF):K 3 AlF 6 =20:80-10:90, SmF 3 :LiF=75:25-90:10,Sm 2 o 3 The content is 1-3wt% of the total amount of molten salt, K 3 AlF 6 The content is 80-90wt% of the total amount of molten salt; and the weighed SmF 3 , LiF, K 3 AlF 6 、Sm 2 o 3 and aluminum ingots were dried and preheated at 200°C for 2 hours for later use.

[0031] (2) K after preheating in step (1) 3AlF 6 Put it into the electrolytic tank, heat up to 800-900°C, wait for K 3 AlF 6 Add preheated SmF after complete melting 3 and LiF; to be SmF 3 After the LiF is completely melted, add the preheated aluminum ingot, and add Sm after the aluminum ingot is melted 2 o 3 until melting;

[0032] (3) Car...

Embodiment 5

[0043] Embodiment 5 (SmF 3 +LiF:K 3 AlF 6 =40:60) of SmF 3 +LiF content is too high, the liquid aluminum is not in contact with the electrolytic cell and cannot be used as a cathode to conduct electricity (the density of the molten salt system is greater than that of liquid aluminum), so samarium cannot be electrolyzed.

[0044] (3) By the comparison of Example 3 and Example 7-9, it can be obtained that the increase of electrolysis temperature can effectively improve the current efficiency, but when the temperature is higher, the SmF 3 The solubility in the molten salt increases, and the samarium after electrolysis dissolves in the molten salt, which is not conducive to product separation. In addition, too high temperature will also cause K 3 AlF 6 Accelerated volatilization, resulting in increased costs, is not conducive to large-scale industrial production applications.

[0045] (4) embodiment 3, embodiment 10-13 are comparatively available, the Sm of embodiment 12 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com