Ge (germanium) element compensation method for CdGeAs2 single crystal growth

A technology of element compensation and crystal growth, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of large variation of Ge content at both ends of the single crystal, uneven Ge composition, inconsistent performance, etc., to achieve Avoid inconsistent crystal properties, uniform Ge elements, and reduce growth costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

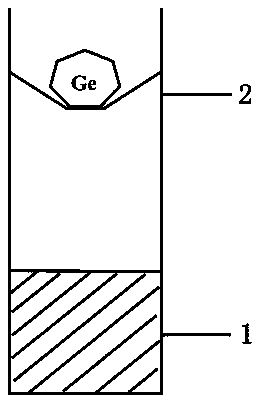

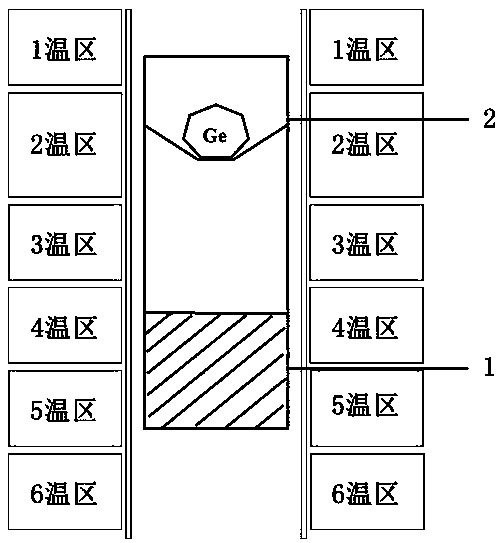

[0016] Embodiment: This method adopts a growth device composed of a single crystal growth crucible 1, a germanium element compensation device 2 and a six-temperature zone growth furnace to control the germanium element compensation for the growth of arsenic, germanium, and cadmium single crystals. This method is completed by the following growth steps :

[0017] A, take out 600g purity and be the arsenic germanium cadmium crystal growth raw material of 99.9999%, put into such as figure 1 The bottom part of the single crystal growth crucible 1 made of quartz is shown;

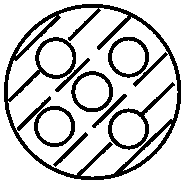

[0018] B. Put 4g of germanium element with a purity of 99.9999% into the germanium element compensation device 2, the material of the germanium element compensation device 2 is high-purity quartz, and the bottom of the germanium element compensation device 2 is as follows figure 2 The shown five-hole mesh structure allows the melted germanium solution to flow into the raw material solution for the growth of ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com