Prefabricated floor slab and prefabricated floor slab mould

A floor slab and mold technology, applied in the field of prefabricated floor slabs and prefabricated floor slab moulds, can solve the problems of increased labor costs and assembly costs, high assembly costs, and large manpower consumption, so as to save labor costs and construction time, use flexibly, and reduce time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

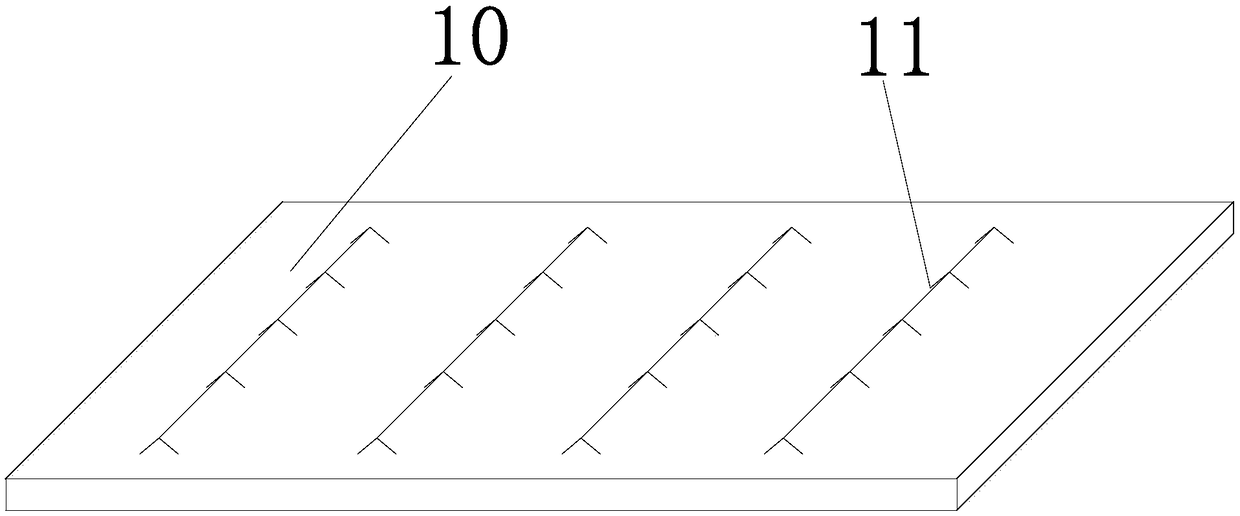

[0029] Such as figure 2 As shown, this embodiment provides a prefabricated floor slab, including a slab body and truss reinforcements arranged in the slab body; the lower chord of the truss reinforcement is buried in the slab body, and its upper chord is located in the post-cast concrete laminated layer, that is, the upper chord of the truss reinforcement is exposed Outside the upper surface of the slab, the post-cast concrete layer is the concrete layer cast on the slab during the on-site construction stage; in the actual production process, in order to increase the friction between the slab and the concrete layer, The upper surface of the slab body is a rough surface; when assembling the above prefabricated floor slab, place the prefabricated floor slab at a preset position, and then cast a concrete laminated layer on the upper surface of the slab body, thereby improving the tensile performance and crack resistance of the building Better performance and anti-seepage perform...

Embodiment 2

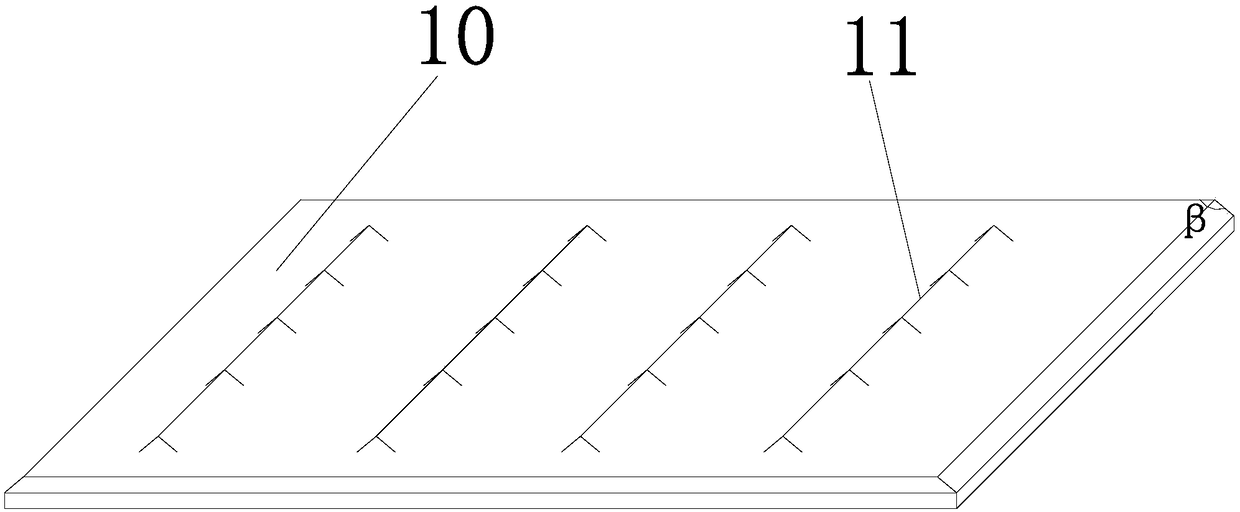

[0033] Such as figure 1 As shown, this embodiment provides a prefabricated floor slab, which includes a slab body and truss bars arranged in the slab body; the lower chord of the truss bars is embedded in the slab body, and its upper chord is located in the post-cast concrete laminated layer.

[0034] In this embodiment, the lower part of the plate body is a cuboid; the angle β between the side surface of the upper part of the plate body and its upper surface is not less than 90°, specifically, the angle β between two sides of the upper part of the plate body and its upper surface The included angle β is not less than 90°, thus corresponding to the inclined plane made by the folded edge of the above-mentioned prefabricated floor mold, which ensures that the building meets the mechanical requirements while reducing the rib surface.

[0035] This embodiment also provides a prefabricated floor mold for making the above-mentioned prefabricated floor, which includes a mold table, a...

Embodiment 3

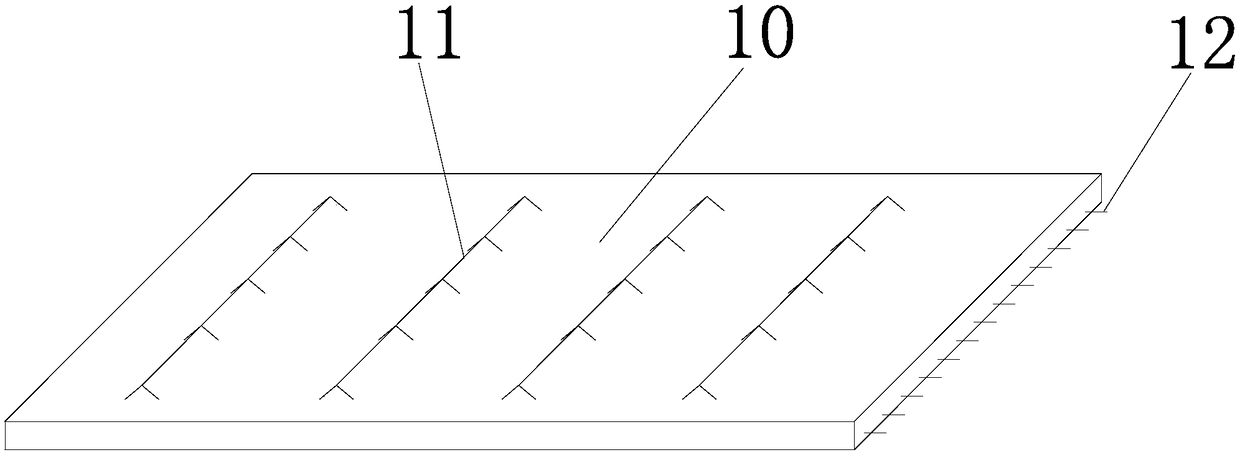

[0039] Such as image 3 As shown, this embodiment provides a prefabricated floor slab, which includes a slab body and truss bars arranged in the slab body; the lower chord of the truss bars is embedded in the slab body, and its upper chord is located in the post-cast concrete laminated layer. In this embodiment, a steel bar with one end protruding from the side of the plate body is arranged in the panel body. The steel bar can determine one or more sides of the current prefabricated floor according to the structure of the current building and the position of the current prefabricated floor in the building. The steel bar can make The connection between adjacent boards is more stable.

[0040] This embodiment also provides a prefabricated floor mold for making the above-mentioned prefabricated floor, which includes a mold table, and also includes a first side form, a second side form, and a third side mold located on the upper surface of the mold table and connected end to end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com