Ultrasound wax prevention and viscosity reduction equipment for oil-well wellhead

An ultrasonic and viscosity-reducing technology, which is applied in wellbore/well parts, cleaning equipment, earthwork drilling and production, etc., can solve the problems of reducing production efficiency, increasing crude oil flow resistance, and corrosion of downhole equipment, so as to improve transmission efficiency and reduce viscosity. Thickness, anti-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

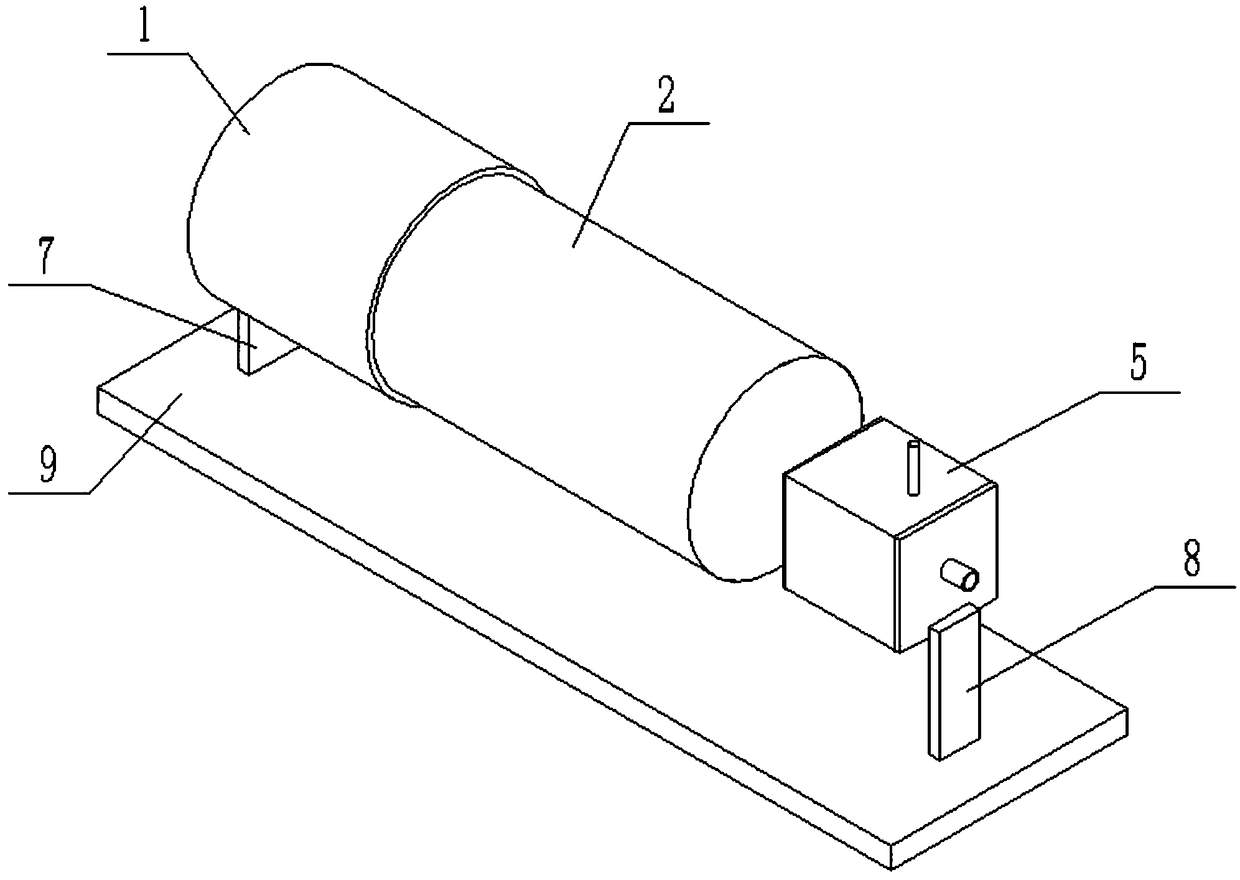

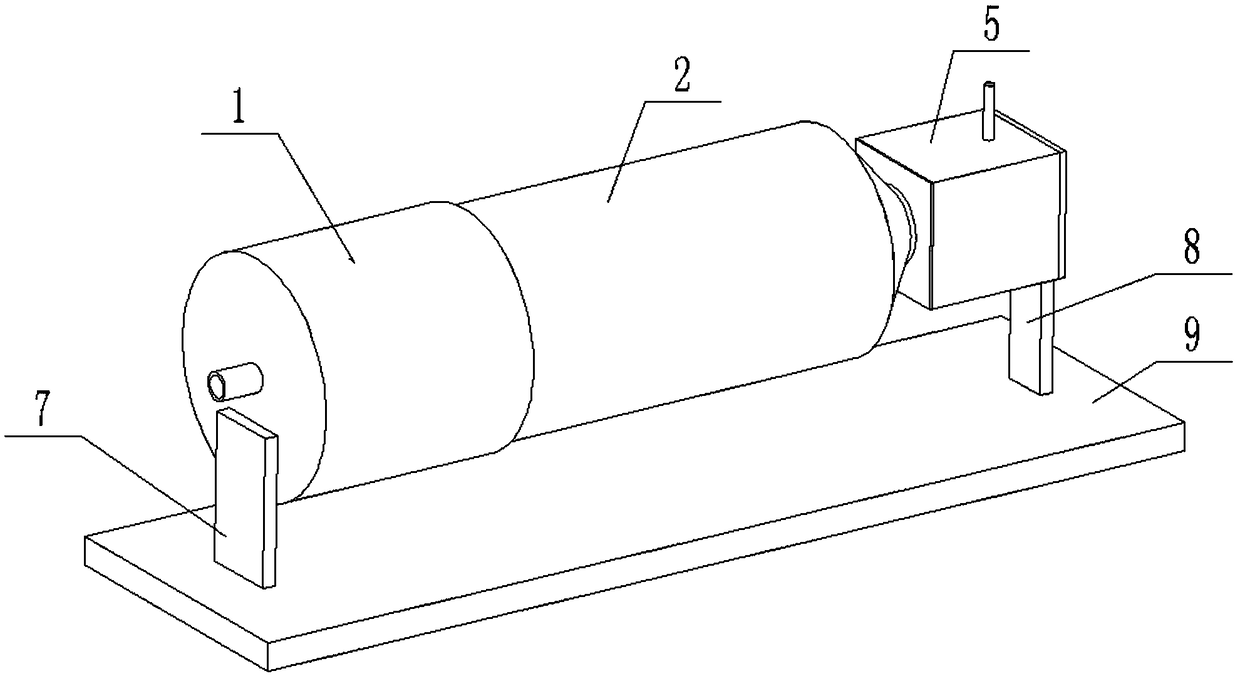

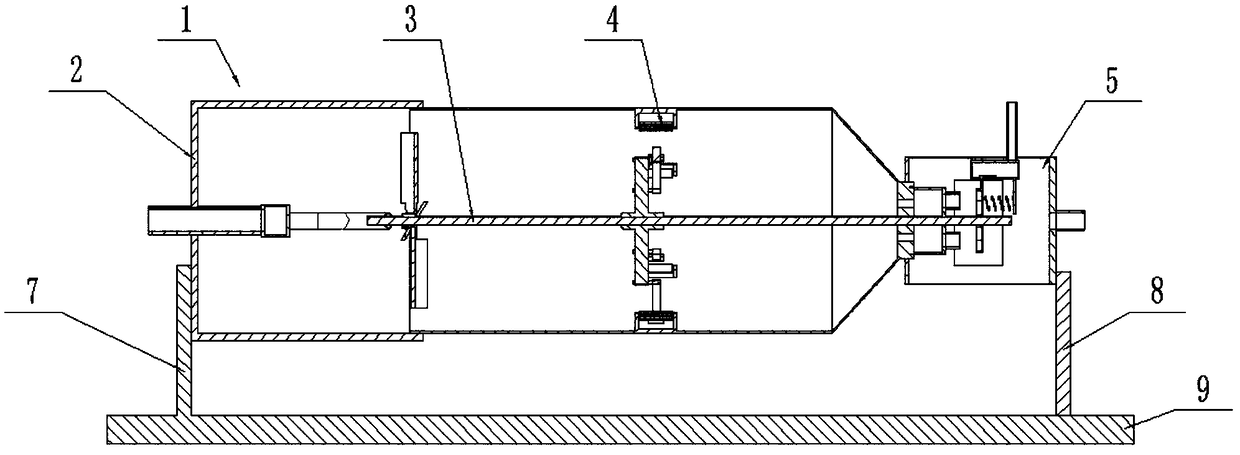

[0032] Such as Figure 1-14 As shown, the wellhead ultrasonic anti-wax and viscosity-reducing equipment for oil wells includes an oil inlet barrel 1, a stirring wax-proof barrel 2, a stirrer 3, multiple vibrators 4, an ultrasonic viscosity-reducing barrel 5, an ultrasonic transducer 6, a front bracket 7, and The rear bracket 8 and the base plate 9, the oil inlet cylinder 1 is fixedly connected to the front side of the top end of the base plate 9 through the front bracket 7; the rear end of the oil inlet cylinder 1 is hermetically connected and connected to the mixing wax-proof cylinder 2; The back end of the stirring wax-proof cylinder 2 is sealed and connected to the ultrasonic viscosity reducing cylinder 5; the agitator 3 is rotatably connected to the inner side of the stirring wax-proof cylinder 2; the inner surface of the stirring wax-proof cylinder 2 is evenly fixed and connected. A vibrator 4; the inner side of the ultrasonic viscosity reduction cylinder 5 is fixedly conn...

specific Embodiment approach 2

[0033] Such as Figure 1-14 As shown, the oil inlet tube 1 includes an oil inlet pipe 1-1, an oil inlet barrel body 1-2, an oil distribution box 1-3, and an injection oil pipe 1-4; the middle end of the oil inlet pipe 1-1 is connected in a sealed manner The front end of the oil inlet barrel body 1-2 and the rear end of the oil inlet pipe 1-1 are inserted into the inner side of the oil inlet barrel body 1-2. The rear end of the oil inlet pipe 1-1 is fixedly connected and connected to the oil distribution box 1-3. The rear end of the oil box 1-3 is fixedly connected to and communicated with two oppositely arranged injection oil pipes 1-4; the rear end of the oil inlet cylinder body 1-2 is sealedly connected and communicated with the stirring wax-proof cylinder 2. When the oil inlet cylinder 1 is in use, after the crude oil enters the oil separator box 1-3 through the oil inlet pipe 1-1, the crude oil is injected out through two injection oil pipes 1-4, and the crude oil is inject...

specific Embodiment approach 3

[0035] Such as Figure 1-14 As shown, the stirring wax-proof cylinder 2 includes a cylindrical cylinder 2-1, a conical cylinder 2-2 without a cone tip, and a short tube 2-3; the cylindrical cylinder 2-1, a cone without a cone tip The cylindrical body 2-2 and the short tube 2-3 are fixedly connected and communicated in sequence from front to back; the front end of the cylindrical body 2-1 is hermetically connected and communicated with the oil inlet cylinder body 1-2; The rear end is connected to the short tube 2-3 in a rotating fit; the rear end of the short tube 2-3 is fixedly connected and connected to the ultrasonic viscosity reducing cylinder 5.

[0036] The agitator 3 includes a stirring shaft 3-1, a rotating seat 3-2, a plurality of swirling inclined plates 3-3, a stirring and percussion mechanism 3-4, a rotating drum 3-5 hollowed out on the front side, and two jet straight Tube 3-6; The rotating seat 3-2 is fixedly connected to the front end of the stirring shaft 3-1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com