Magnetic levitation bearing structure and magnetic levitation motor

A technology of magnetic suspension bearing and clamping structure, which is applied to magnetic bearings, bearings, shafts and bearings, etc., can solve the problem that the interference between the shell and the radial ring cannot be satisfied, affect the reliability of the magnetic suspension bearing structure, and affect the coaxiality of the magnetic suspension assembly. Accuracy and other issues, to avoid multiple disassembly and assembly, reduce disturbance, reduce the amplitude and intensity of high-frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

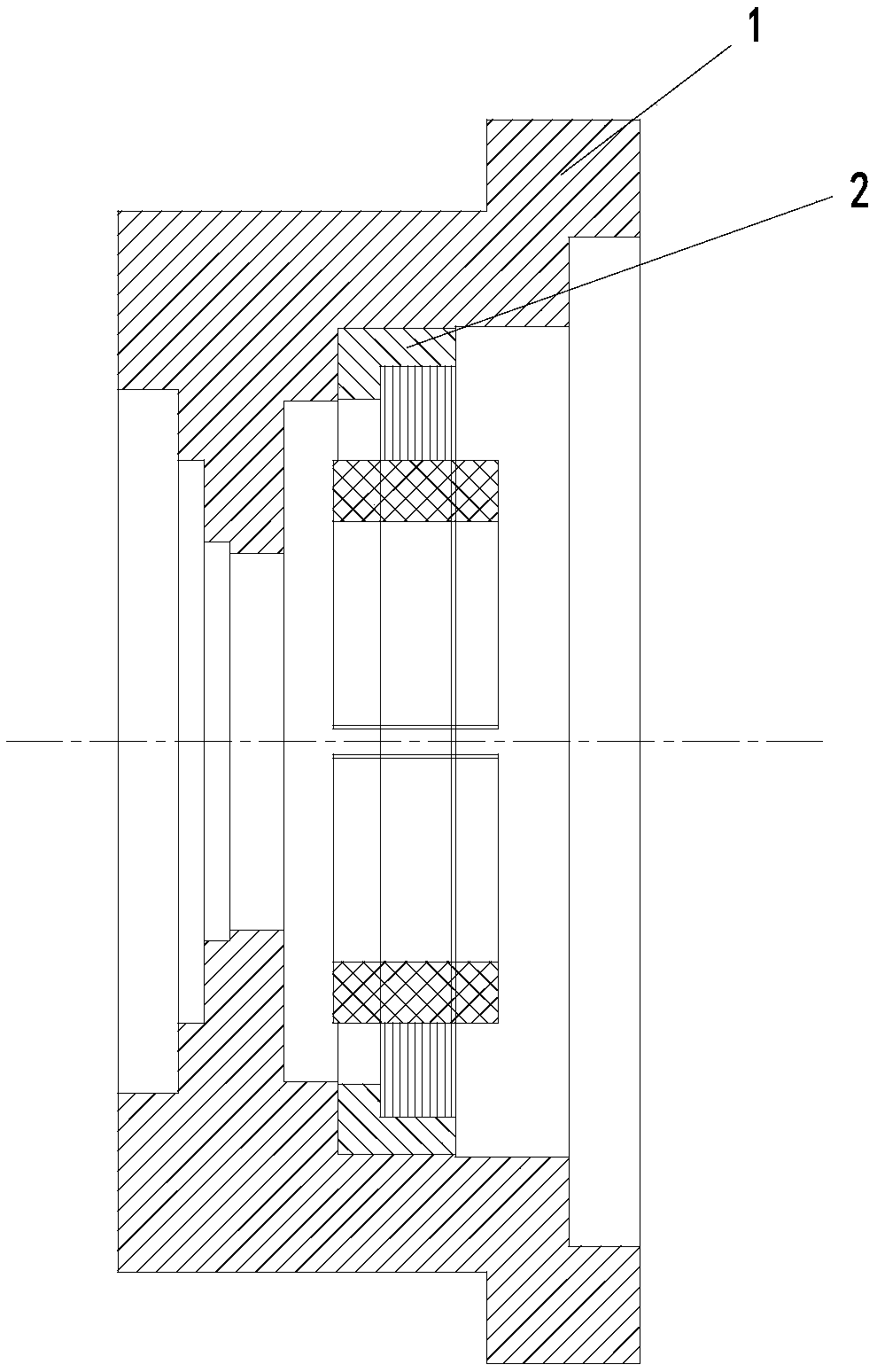

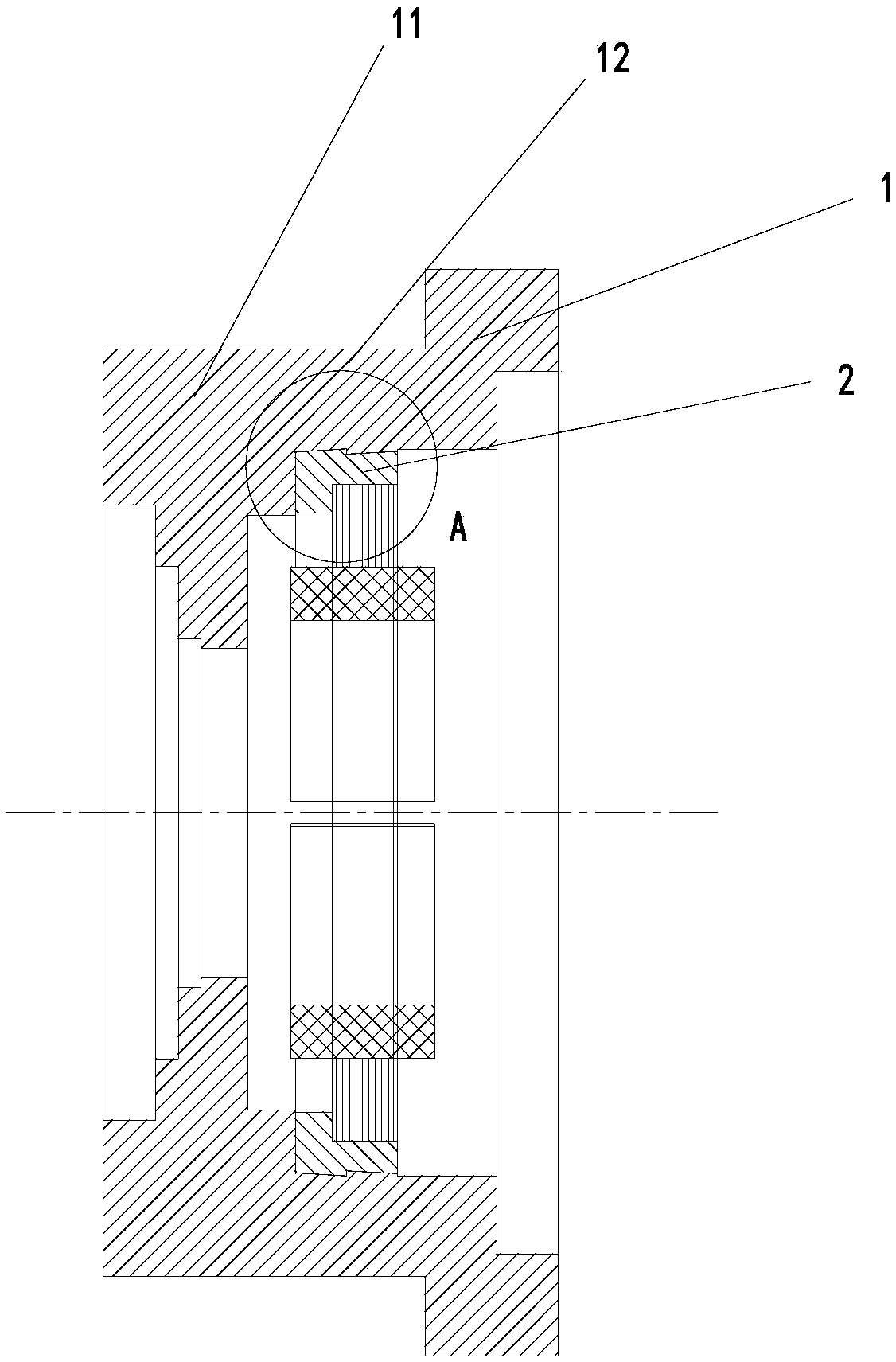

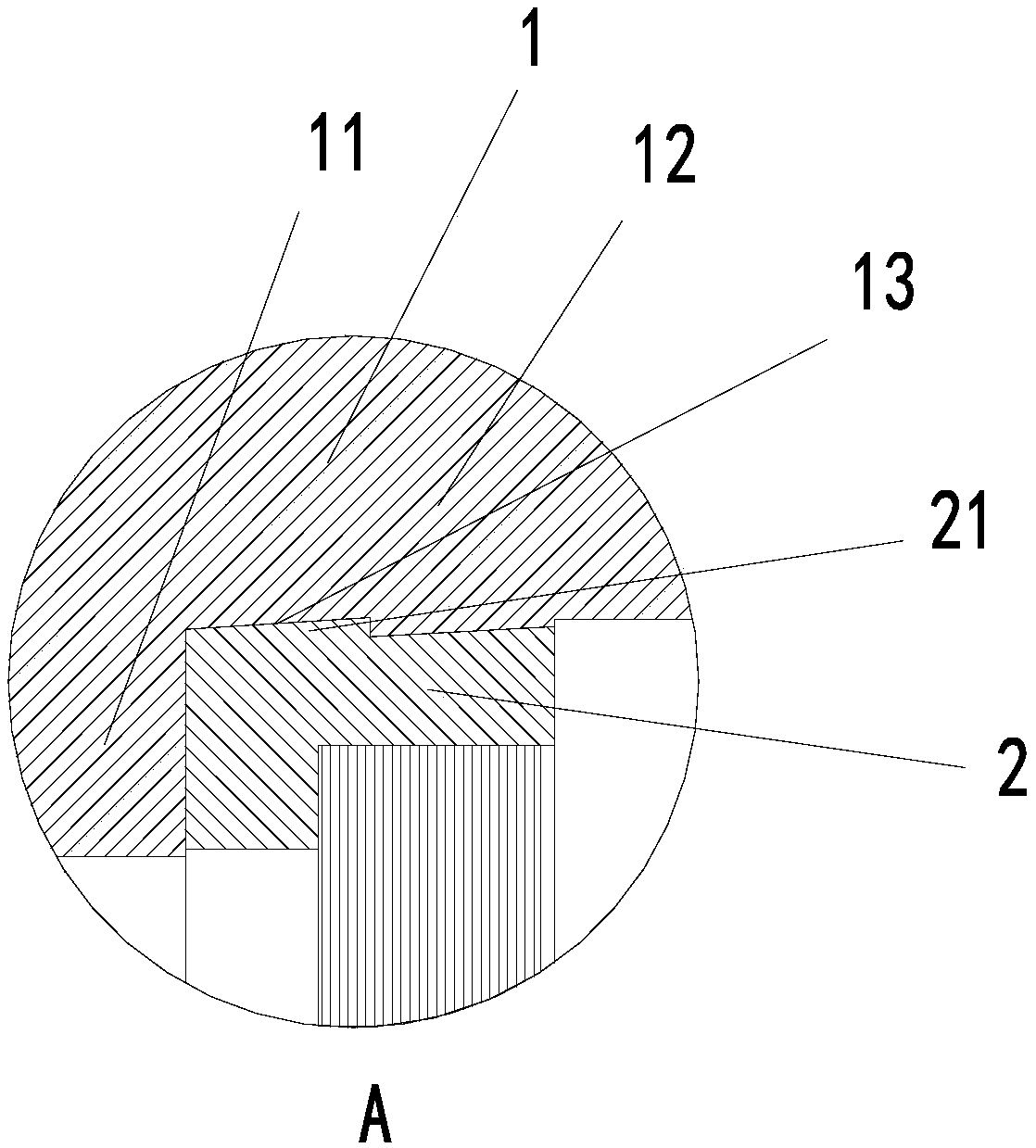

[0028] Magnetic levitation application products are ultra-high-speed machines. The magnetic levitation bearing is its key component. Once the magnetic levitation system breaks down, the magnetic levitation product will not be able to start levitation and cannot operate normally, resulting in production loss. The position limitation and fixation by positive fit cannot satisfy the effective position limitation and fixation of the casing 1 and the radial ring 2 under the condition of temperature rise or deformation, and thus cannot satisfy the reliability of the magnetic suspension bearing.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com